TABLE OF CONTENTS

Customer Support....................................................................................................................4

Introduction.............................................................................................................................5

Transport and Handling............................................................................................................5

Sensor Identification ................................................................................................................5

Electrostatic Discharge (ESD) & Circuit Protection .....................................................................5

Using This Manual....................................................................................................................6

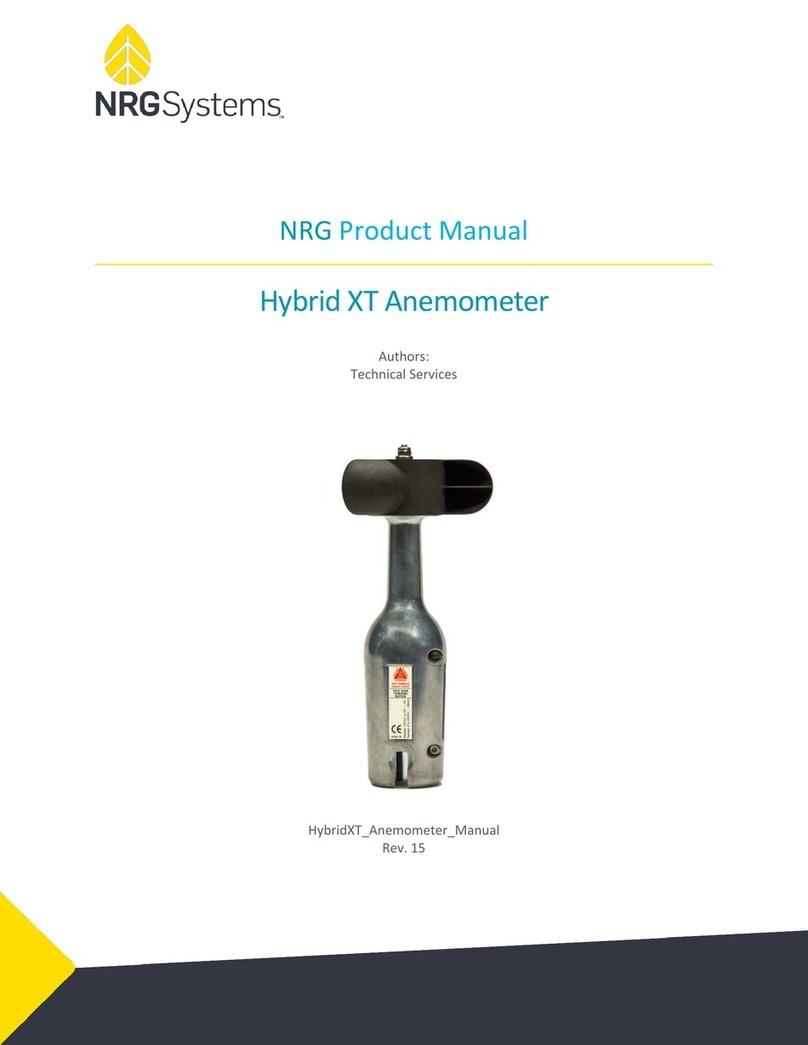

Hybrid XT Anemometer............................................................................................................7

Operation ...................................................................................................................................................... 7

Calibration.....................................................................................................................................................7

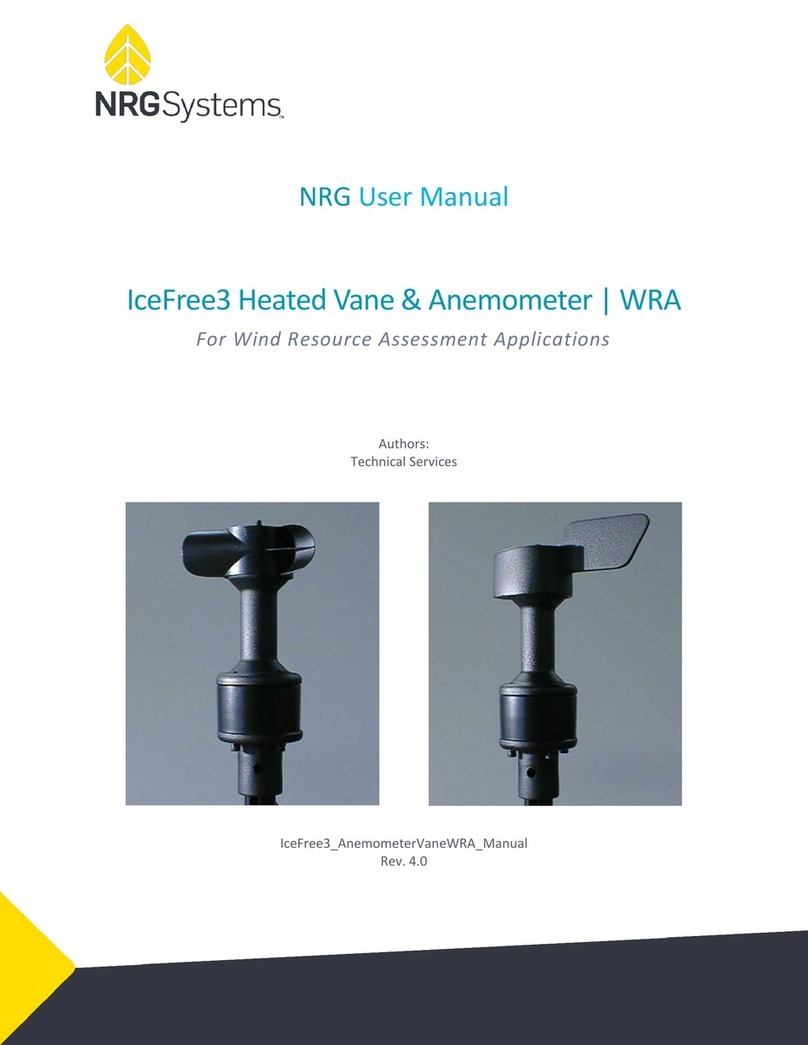

Hybrid XT Vane ........................................................................................................................7

Operation ...................................................................................................................................................... 7

South Mark....................................................................................................................................................7

Sensor Heater ..........................................................................................................................8

Operation ...................................................................................................................................................... 8

Power Considerations....................................................................................................................................8

Heater Power Supply Requirements ..............................................................................................................8

Sensor Power Supply Requirements............................................................................................................... 9

Sensor Installation.................................................................................................................. 10

Parts Required............................................................................................................................................. 10

Mounting Mast Orientation.................................................................................................... 12

Prepare Shield........................................................................................................................ 12

Mount Connector................................................................................................................... 13

Mount Sensor ........................................................................................................................ 14

Vane:........................................................................................................................................................... 15

Note: This configuration requires the external sense resistor NRG # 17884 (RES 125 OHM 1-2W 0.1% Axial)

.................................................................................................................................................................... 15

Boom bearing should be entered as actual, based on the site. Vane Mounting Angle is always

270 based on the bolt hole alignment, if "toward rotor" is away from the tower. Vane

Mounting Angle would be 90 if "toward rotor" is towards the tower............................................. 15

Logger Wiring:............................................................................................................................................. 15

Logger Programming................................................................................................................................... 16

Anemometer: .............................................................................................................................................. 16

Vane:........................................................................................................................................................... 16