Thank you for purchasing this piece of Barloworld Scientific equipment. To get the best performance from the

equipment, and for your own safety, please read these instructions carefully before use.

This equipment is designed to operate under the following conditions:-

For indoor use only

Use in a well ventilated area

Ambient temperature range +5°C to +40°C

Altitude to 2000m

Relative humidity not exceeding 80%

Pollution degree 2 IEC664

If the equipment is not used in the manner described in this manual the protection provided by the equipment may

be impaired.

General Description

The Stuart sample concentrator, when used in conjunction with a Stuart block heater accelerates the evaporation

process of samples of solution for analysis. With the heat generated from the block heater and the steady flow of

gas above the surface of the sample, to carry away evaporated products, the rate of sample concentration is

significantly increased. The Stuart sample concentrator is only compatible with the three block, SBH130D/3 or

SBH200D/3, models of Stuart block heater.

The sample concentrator is made up of gas chamber sited on a height adjustable stand, to allow accurate

positioning above the samples. Hyperdermic needles penetrate a membrane within the gas chamber and carry the

gas from the chamber into the sample test tubes.

Safety Advice Before Use

Care should be taken when using hot apparatus, high temperatures can cause serious burns and ignite

combustible material

Never move or carry the unit when in use

Always use a gas regulator to control the flow of gas to the sample concentrator, do not exceed 2 psi at the

intake valve

Do not put hot objects near combustible objects

Do not place liquid directly into your block heater

Installation

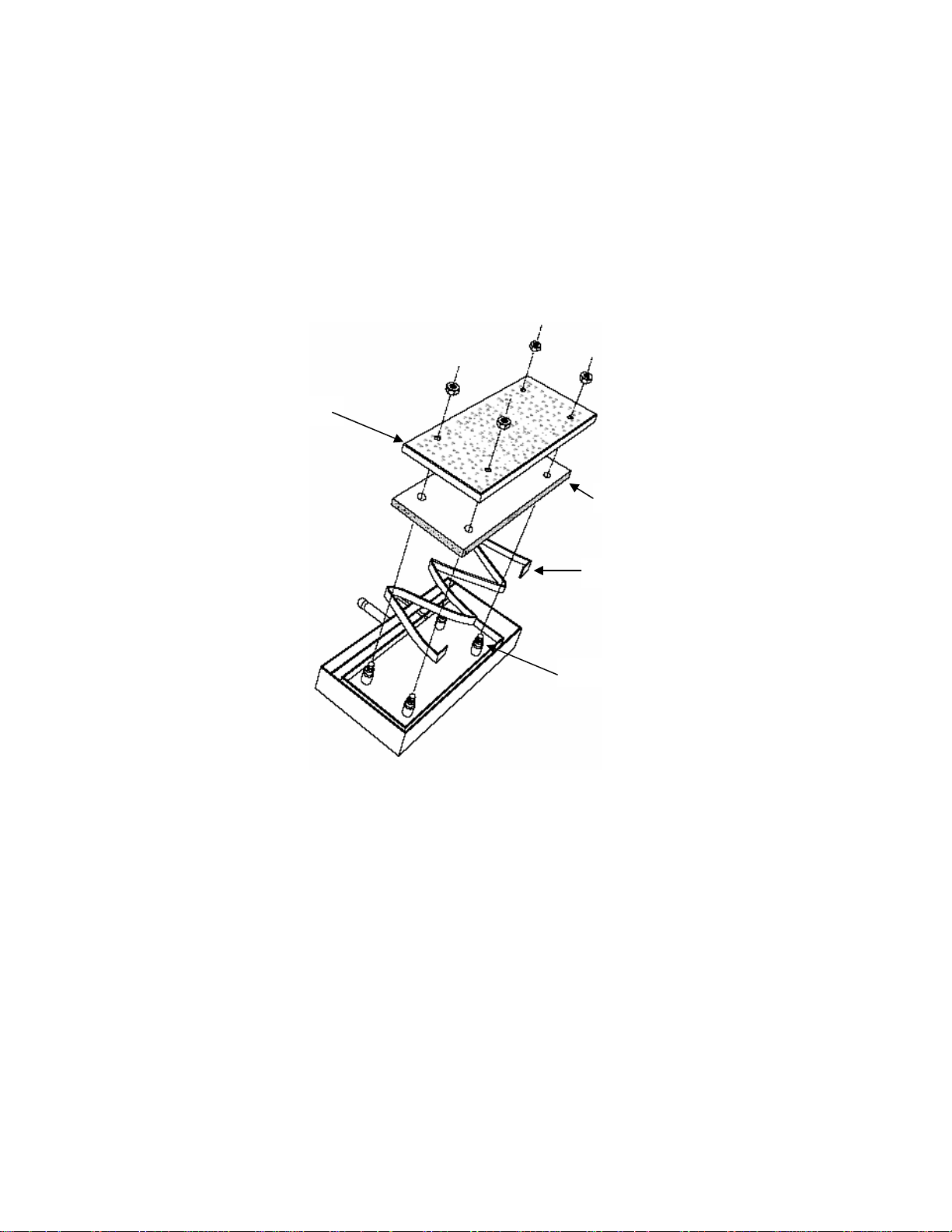

To help reduce packaging material the sample concentrator is delivered in three parts; the base board, the column

and carriage, and the gas chamber. Follow the instructions and diagram below to reassemble:

1. Unscrew the fastening knob at the rear of the base board, locate the column on the two pins in the

support bracket. Tighten the fastening knob to secure the column in place.

2. Insert the locating pin at the rear of the gas chamber into gas chamber location hole on the carriage,

taking care to line up the positioning pin, tighten the locking nut at the side of the carriage to secure the

gas chambers position.