Machine Inspection

1. Now that the machine is unpacked, remember to

recycle all the packing materials.

2. Inspect the machine for damage or missing

components. If damage is found, contact the local

freight company to le a claim.

• Located in the far left side of the control panel is the

Power Switch. The toggle switch is in the “OFF”

position when it is down and is in the “ON” position

when it is up. When turned on, the pump will turn on

and pressurize the system. Note: the Power Switch

will not work unless the Circuit Breaker is in the reset

(lower, locked) position.

• Located next to the Power Switch is the Circuit

Breaker The circuit breaker is rated for 10 amps.

The machine is shipped with the circuit breaker in the

“Disconnected” or tripped position. The circuit breaker

is reset by depressing the plunger until is click in to the

lower, locked position.

• The Battery Meter is located in the center of the

control panel. The battery meter is a 10 segment LED

display. When fully charged, the right most LED will

be illuminated. As the battery discharges, the LED

will move to the left indicating a 10% lower amount of

battery charge. When the battery is 70% discharged

the 2nd LED segment from the left will be ashing.

When the battery is 80% discharged, the two left most

LEDs will ash. See the section on Battery Charging

for further instructions.

• Pump Pressure Control is to the right of the Battery

Meter. The pump pressure control varies the speed of

the pump. This will decrease or increase the pressure

and ow of the pump. To decrease the pressure/

ow, turn the control knob counter clockwise. To

increase the pump pressure/ow, turn the control knob

clockwise.

• Spray Bar Switch is located on the right-hand side

of the control panel. To turn the spray bars on, ip this

switch to the “UP” position. Note: The spray bars will

not work unless the Power Switch is “On”, powering

the pump.

Solution Pump - The solution pump is a self-priming 60

PSI pump. It has a pressure switch that will shut o when

the pressure reaches 60 psi. The pump will turn back on

when the pressure drops below 45 psi.

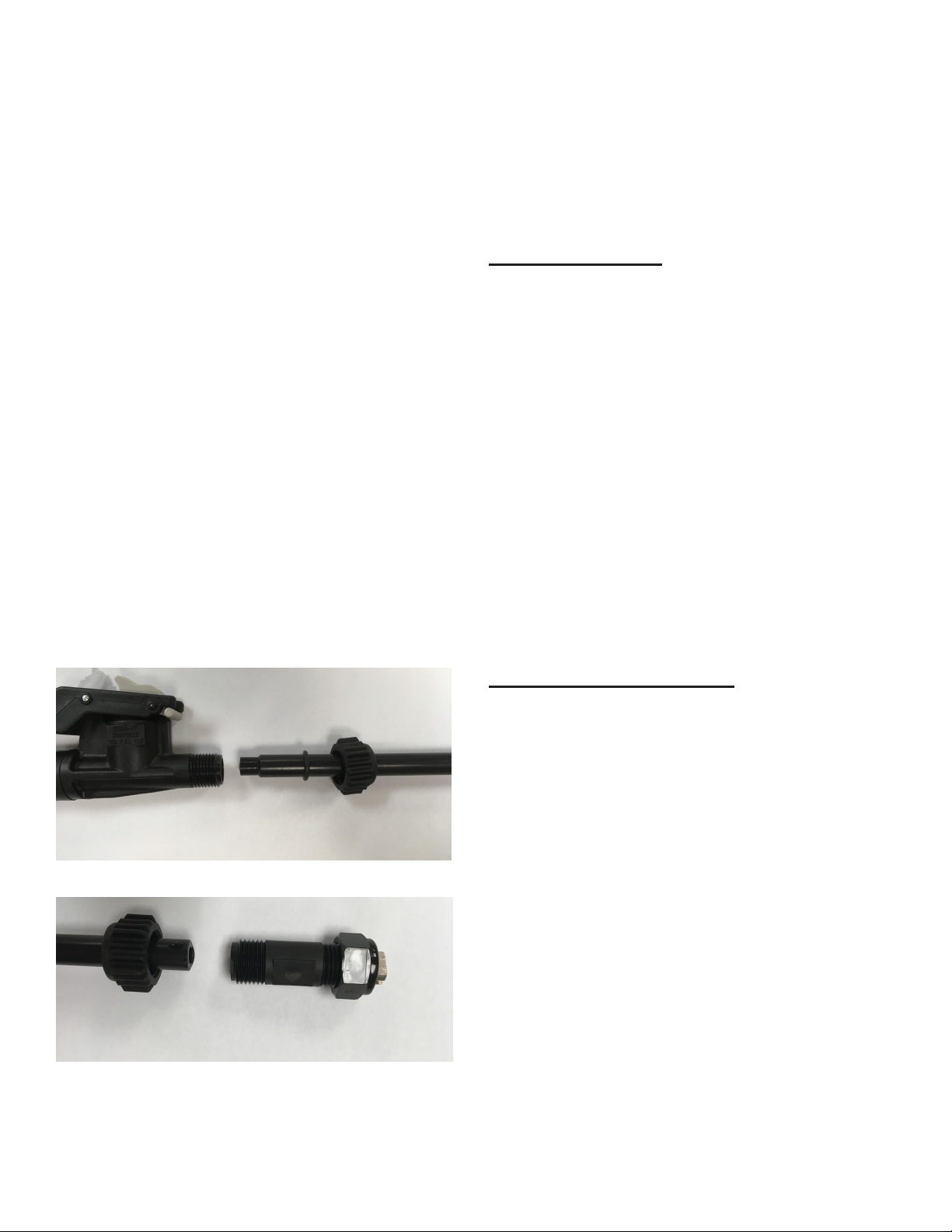

In-Line Screen - The solution pump is protected from

debris that may enter the solution tank by an in-line lter

screen. The solution screen is located under the machine

near the back. There is a ball valve just ahead of the In-

line screen. To clean the screen, shut the ball valve and

unscrew the clear plastic sight glass. The screen can be

removed and rinsed under running water. Replace the

screen and re-install the sight glass. Open the ball valve to

allow water to ow from the solution tank to the pump.

Center Spray Bar - The center spray bar contains two

spray tips that spray in an overlapping fan shape. Each tip

will ow 0.1 GPM of solution when the pump is at 40 PSI

running pressure (nominal.) To turn on the Center Spray

Bar, turn on the Power Switch and the Spray bar Switch.

Unpacking Instructions

1. Carefully cut the two (2) bands from around the carton.

2. Remove the staples and open the top aps.

3. Remove the staples from the bottom of the carton

attached to the pallet.

4. Remove the carton.

5. Locate the small box under the machine, remove from

the pallet and set aside.

6. One at a time, unbolt the front axle bolt and remove

the lag screws holding the pallet mounting bracket.

Reinstall the rst axle bolt before working on the

second side. -This will free the machine from the

pallet.

7. Locate the rear of the machine where the handle is

located.

8. Use the handle to back the machine o the pallet,

lifting the caster wheels o the pallet and setting them

on the oor.

9. Once the caster wheels are on the oor, press down

to pivot the machine’s weight onto the caster wheels,

lifting the 10” wheels o the pallet.

10. Back the machine up until the 10” wheels are clear of

the pallet. Set all the wheels on the ground.

11. Remove and read all operation instructions.

12. Switch the circuit breaker to the “ON” position on the

control panel.

13. Recycle the carton and pallet.

Intended Use

The Opti-Mist 20B is intended for commercial use, for

spraying of liquid solutions on level oors in an indoor

environment, for example in hotels, schools, hospitals,

factories, shops, oces and retail businesses. The

spraying settings can be adjusted to suit the spraying task.

Water quantity, pump pressure, walking speed and solution

concentration can be adjusted by the user.

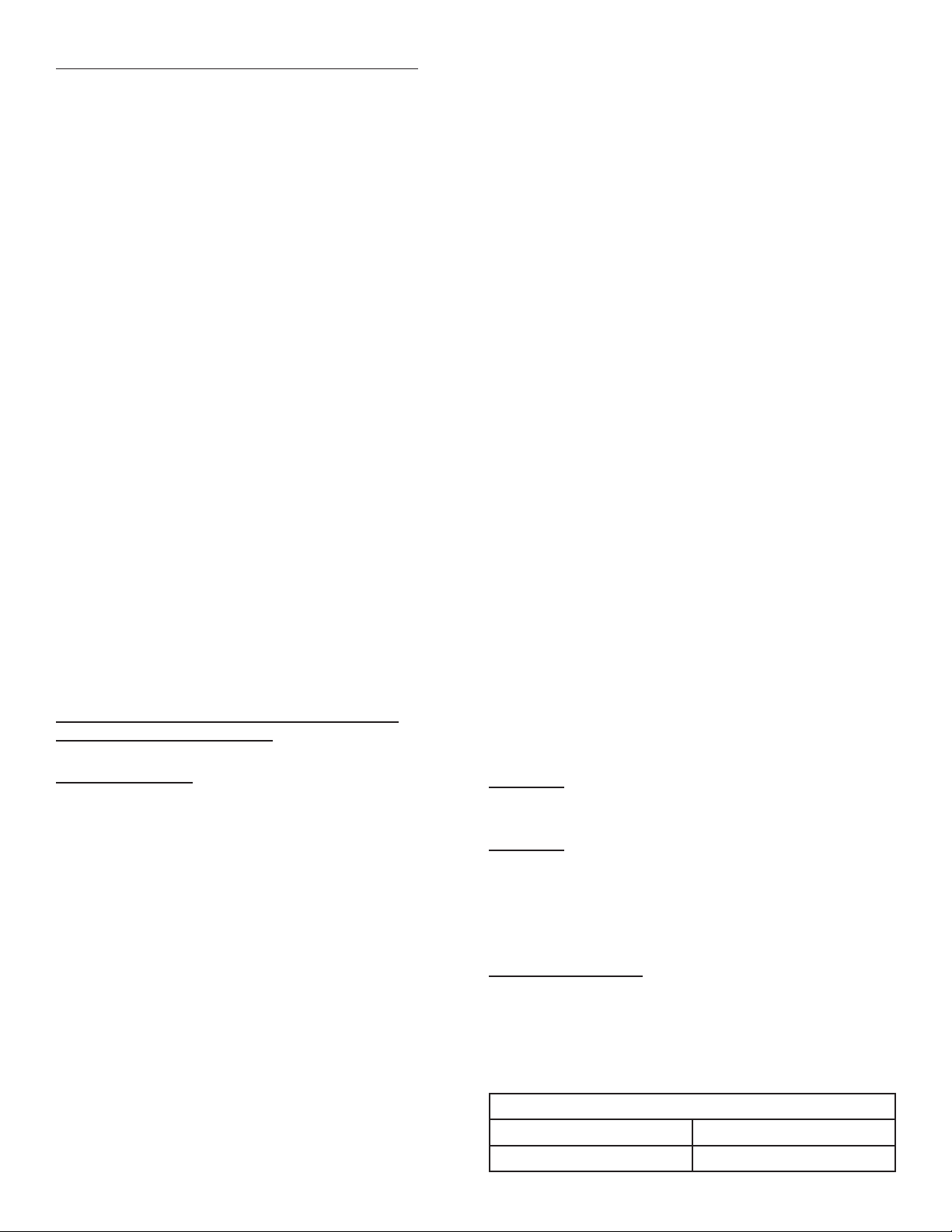

Machine Components

Solution Tank - The solution tank is the plastic tank body.

It has a capacity of 20 gallons (75 liters.)

Control Panel - The operator control panel is located at

the upper rear area of the machine. Operator controls are

positioned for ease of use, and include icons for simplied

user training. This panel has components that control

various machine functions: