SATA UBE | 4

Scope of supply (standard version)

UBE spray gun with spraying tube and connection for dispos-

able cans

Technical Data

Maximum Pressure: 10 bar (145

psi)

Max. temperature of the coating material: 80° C

Air consumption at 3 bar (44 psi): approx. 200

Nl/min

Weight (without can): 660 g

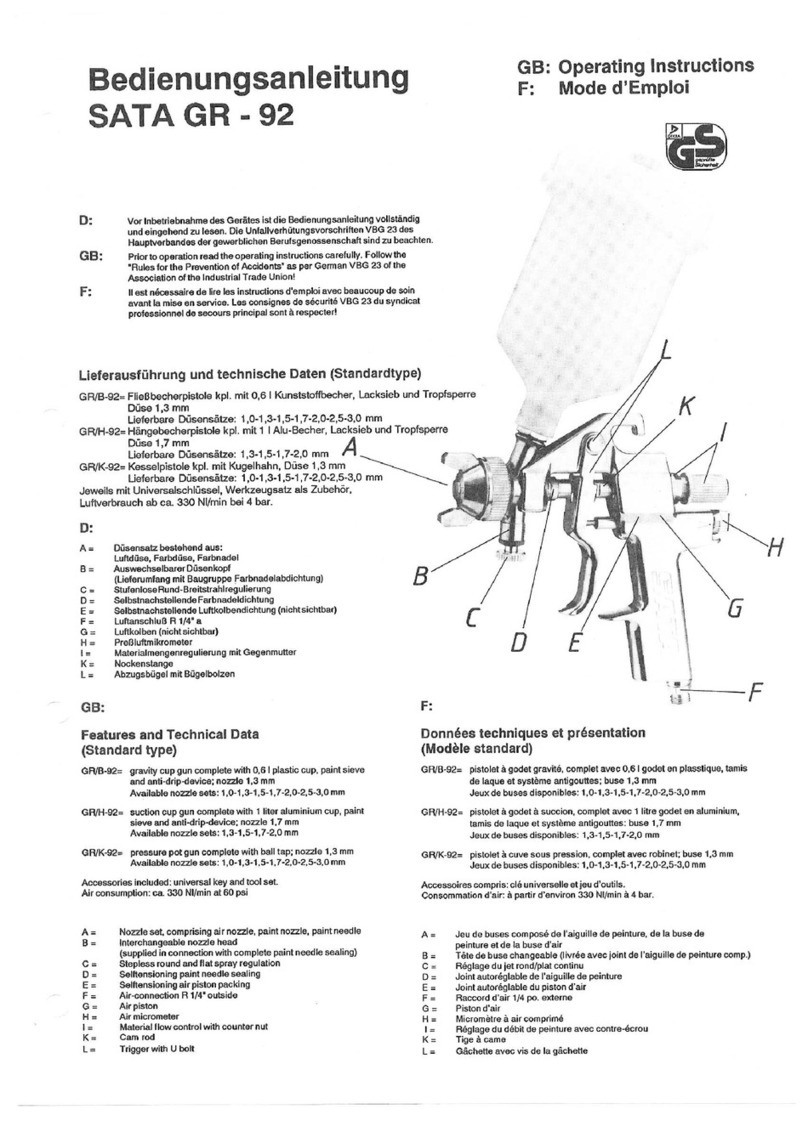

2. Functional Description

The SATA UBE is suitable for applying underbody protection and

stone chip protection materials, cold cleaner etc. from one-way

cans.

Materials that are abrasive, acidic or contain benzine must not be

used. The compressed air required for spraying is supplied via

the air connection which is screwed into the spray gun handle.

Pulling the trigger up to the first pressure point opens the air

valve. Pulling the trigger further pulls out the paint needle from

the fluid tip. The spraying medium then flows out of the fluid tip

and is atomised by the compressed air flow at the same time.

3. Safety Instructions

Warning! Attention!

Please note:

Never point the pressurised cup guns at yourself, at third per-

sons or animals. Solvents, cleaning liquids and thinners can

cause severe burns. Only the quantities of solvents, cleaning

agents and paints required for work progress should be pre-

sent in the direct surroundings of the application device (after

work, solvents and paints must be returned to their designated

storage rooms). Prior to any repair work, the device must be

disconnected from the air supply.

Prior to putting the device into operation, especially after

each cleaning and repair, check all screws and nuts for

tight fit as well as the sealing performance of gun and

hose.

Defective components must be replaced or repaired accord-

ingly. To obtain best possible coating results, and for maximum

safety, only use original spare parts.

Ensure that there are no sources of ignition (e.g. open flames,

burning cigarettes, lamps without ex-protection etc.) present

during the painting process, as easily flammable gas mixtures

are being generated.

Please observe safety regulations when painting (respiratory

protection etc.). Appropriate ear protection is required, as the

sound level of 85 dB (A) may be exceeded when painting under

higher pressure levels.

During use of the pressurised cup spray gun, no harmful vibra-

tions are transmitted which could affect the painter.

Recoil forces are minimal.

The use of this product in explosion hazard zones classified in

Category O is prohibited.

4. Use

Prior to putting the unit/spray gun into operation, carefully read

the complete operating instructions which must be strictly fol-

lowed. The instruction manual should then be safely kept in a

place accessible to every user of the equipment. The unit/spray

gun should only be operated by qualified staff (professional

users). Inappropriate use of the unit/spray gun, technical modi-

fications of any kind or the combination with non-original parts

could cause material damage, severe injury of either the operator

himself or third parties including animals, or even death. SATA

will not assume any liability for damages resulting from disre-

garding the operating instructions. The valid safety, workplace

and worker health protection regulations of the respective coun-

try in which the pressurised cup gun is operated must be strictly

followed (e.g. the German Regulations for Accident Prevention

BGR 500 (BGV D25) and BGV D24 issued by the Central

Officefor Statutory Accident Insurance and Prevention, etc.).

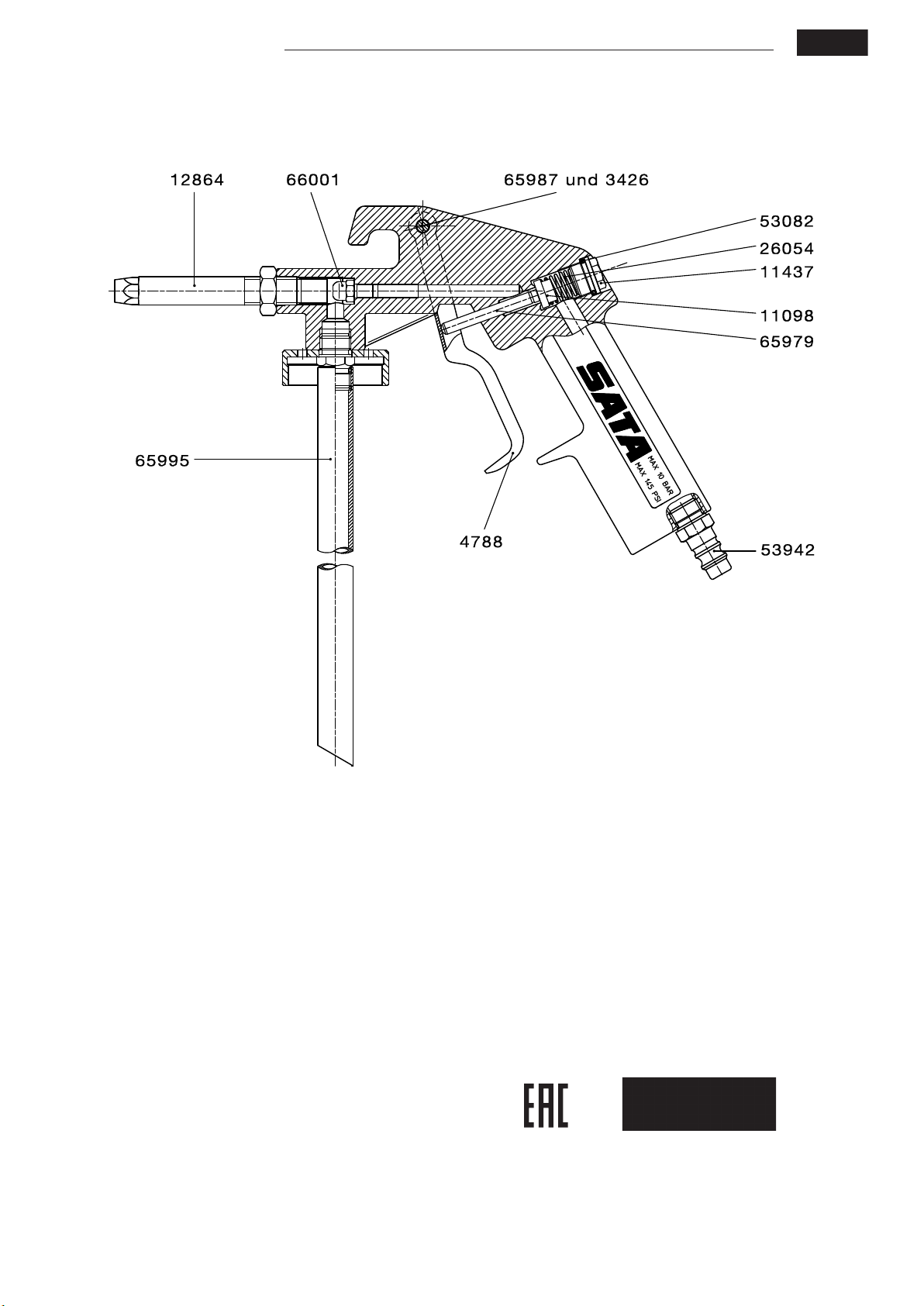

a) Prior to putting the unit into operation, check the spraying tube

for clogged sections. In particular after repair work, check

all screws and nuts for tight fit; tighten them if necessary.

The spray gun is immediately ready for operation after

removal of the packaging. The adjustable spraying tube

has been adjusted by the manufacturer to medium mate-

rial viscosity and fixed by means of the counter nut. By

adjusting the spraying tube correspondingly, the gun can

be adapted to the respective material composition. For

thin materials, the tube must be screwed in; and for high

viscosity materials it must be extended sufficiently far.

During adjustment, watch the spray pattern while pulling the

trigger (4788). When the pattern reaches optimum shape, fix

the counter nut.

b) The air connection is at the spray gun handle. Before

assembly, the air hose should be blown out. The air hose

must be solvent-resistant and show a pressure strength of

minimum 10 bars (150 psi) and a total electrical resistance of

less than 100 Mio. W.

5. Cleaning and Maintenance

a) Thoroughly flush the srpay gun with thinner or cleaning liquid.

b) Clean air cap with a brush. Do not immerse the gun in thinner

or cleaning liquid.

c) Never use improper tools to clean dirty drillings. Remove paint

residues at the spraying tube thread.

Warning! Attention!

Clogged drillings in the gun lid may cause the can to

explode.

d) Prior to any maintenance, the device must be disconnected

from the air supply.

e) Lubricate air piston and the spray-

ing pipe thread (12864)with oil on occasion.

Apart from that, the sturdy spray gun SATA UBE does not

require any further maintenance.

Note!

The spray gun can be manually cleaned with solvents or clean-

ing agents or in a conventional spray gun washing machine.

The procedures mentioned below will damage the gun/

system and may lead to expiry of the explosion proofness

certificate as well as total loss of any warranty:

• Immersing the paint spray gun in solvent or cleaning agents

for a period longer than required for the cleaning process as

such

• Failure to remove the paint spray gun from the gun washing

machine after nishing the cleaning process

• Cleaning the spray gun in ultrasound cleaning systems

EN

54635-BAL SATA UBE.indd 4 14.09.2015 10:51:00