4

Once the terminal has been configured, press <F12> to prompt if the setup is to be saved. Select Yes by pressing space and

then press <F12> again to exit setup mode. If any IP addresses or Ethernet settings have been defined or edited, the terminal

must now be power cycled by using the switch at the rear of the terminal (ensure that no serially connected host is present prior to

power cycling the terminal). If the host server is connected and active, pressing return (if Auto Connect was set to OFF) should

now display a server login prompt.

Each of the defined servers may be selected by using <ALT> and a function key. For example to connect to a server which has

been defined as Remote IP Address 3, press <ALT> and <F4> (since the IP addresses are defined from 0 to 11 and the function

keys are labeled 1 through to 12).

When connecting to a server which is switched OFF or does not have telnet configured, a 10 second timeout will occur when the

server is selected (if Auto Connect is ON), or after pressing return when the server is selected (if Auto Connect is OFF). During

this 10 second timeout, it is not possible to select another server or enter setup.

Please ensure that the Page Length is set to ‘1*Lines’ in the Display Setup (F1 in setup) to prevent possible problems when

switching between different servers.

Technical Specifications

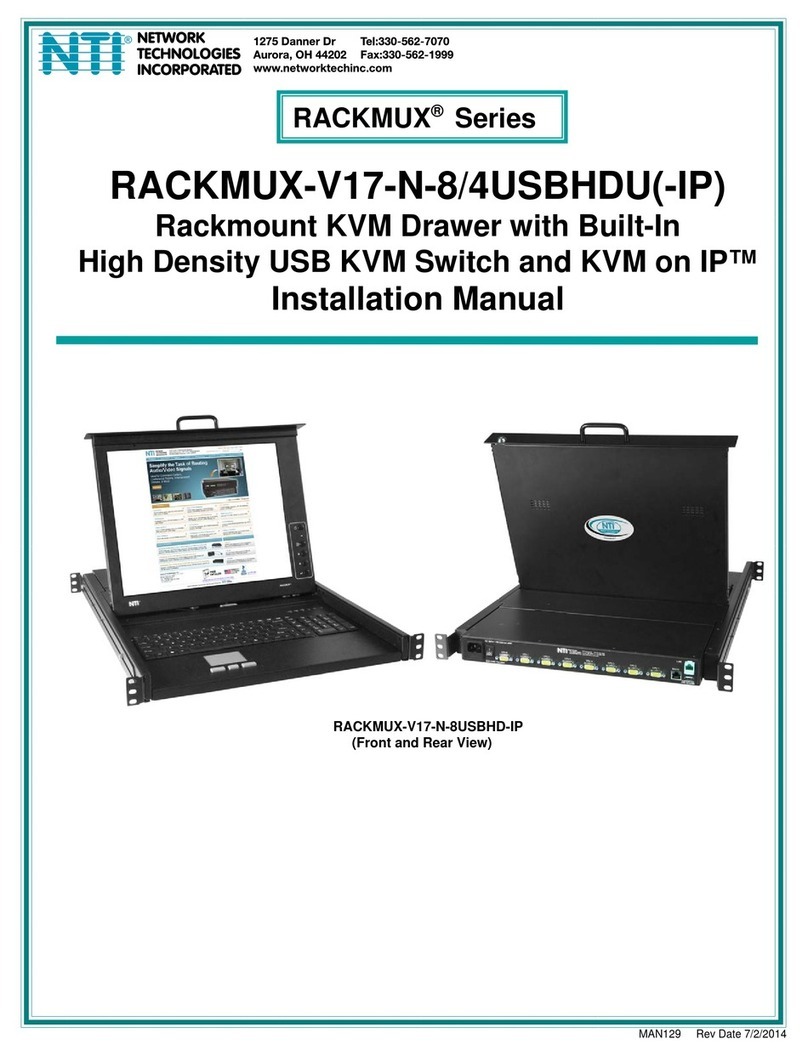

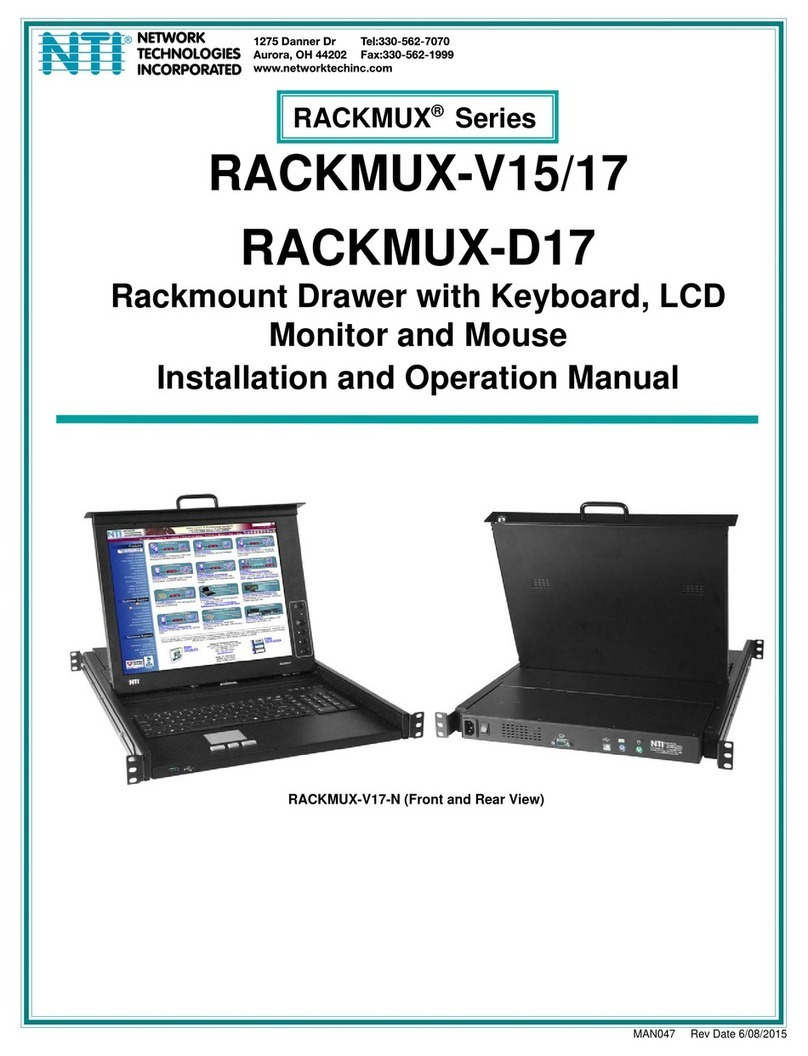

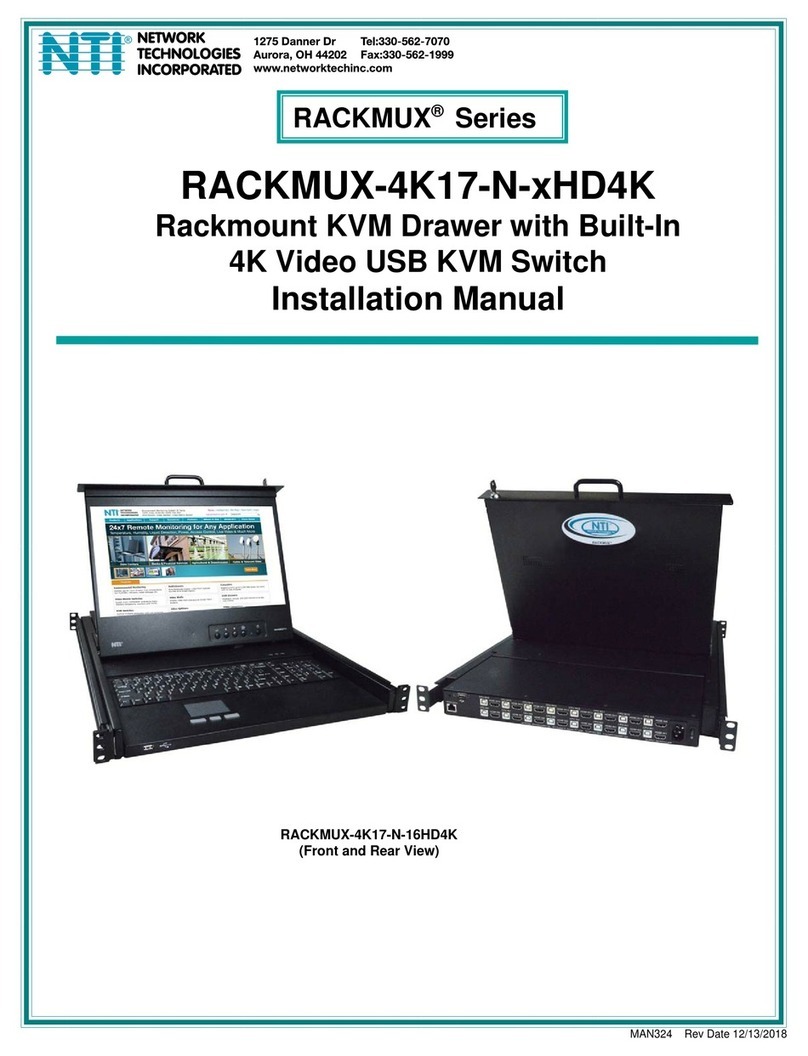

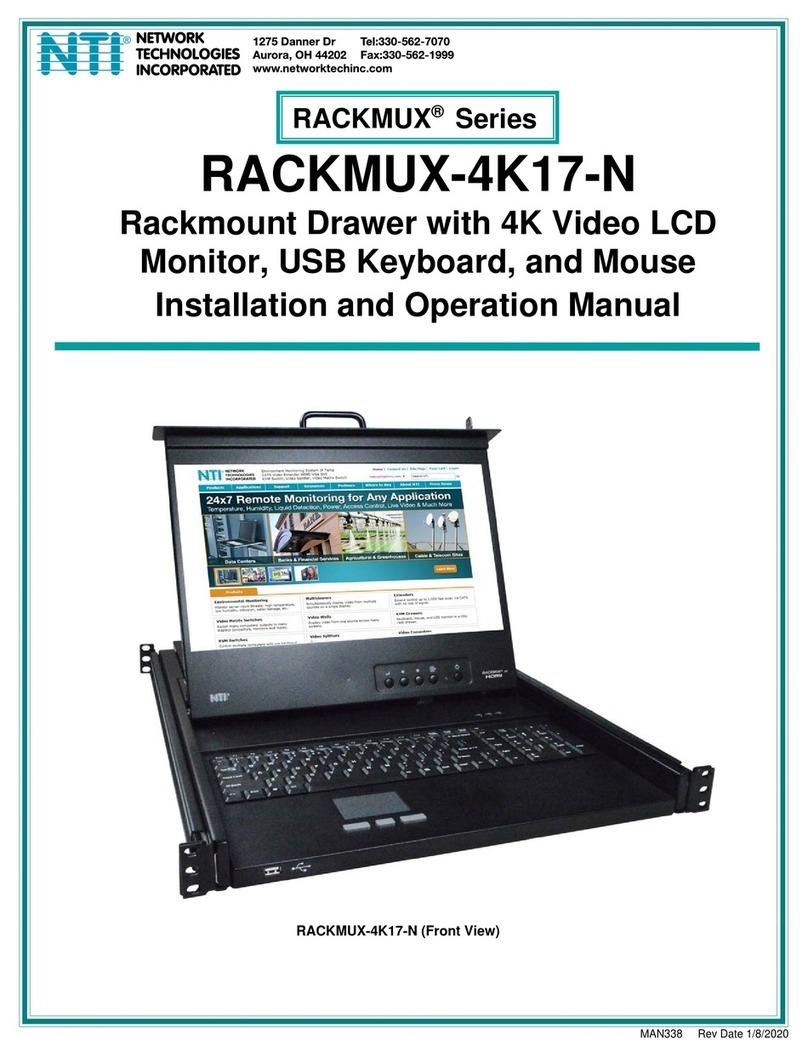

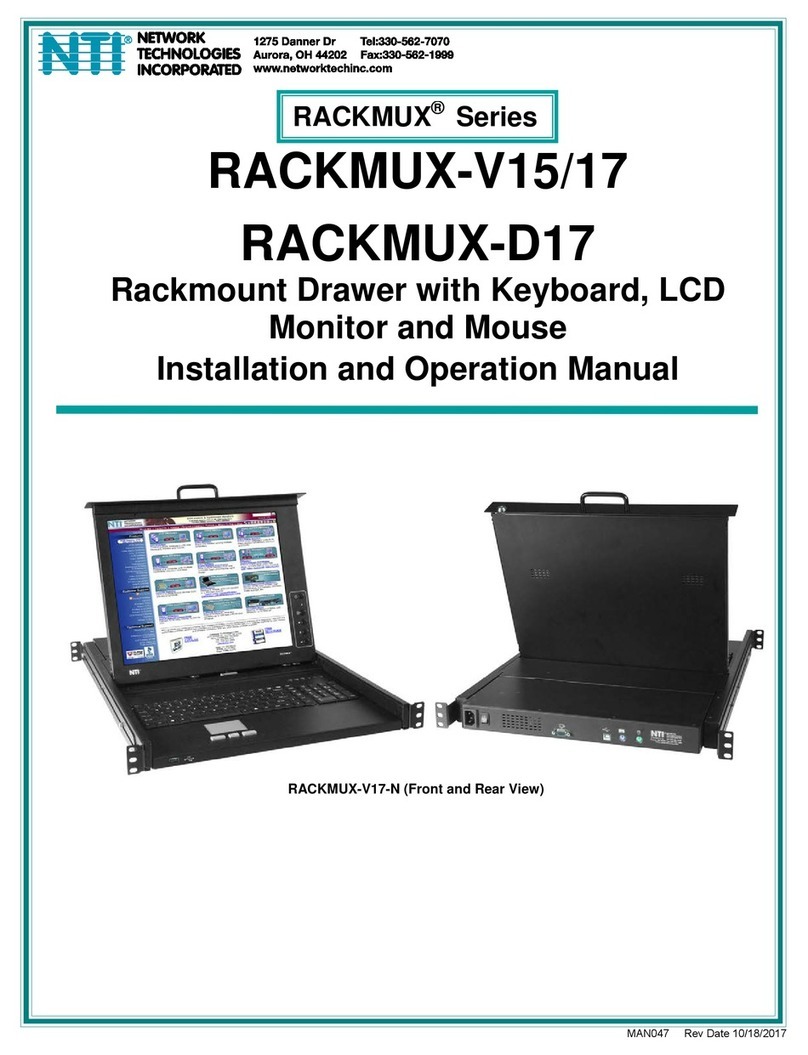

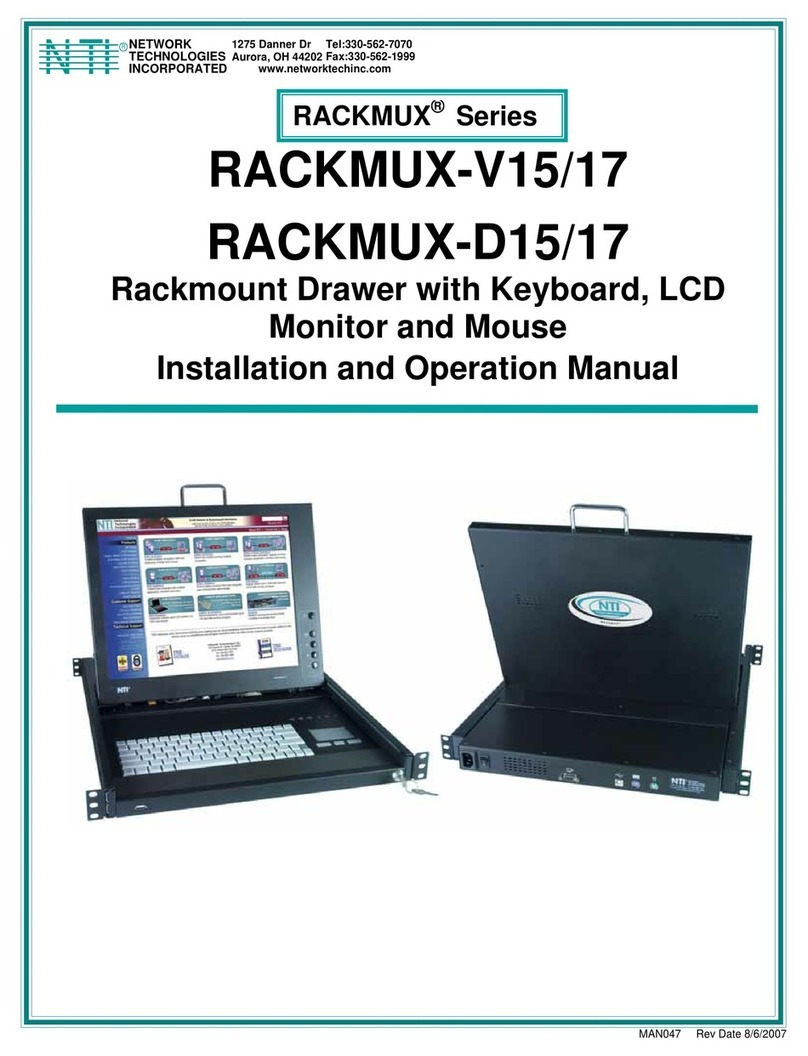

Physical

Size (In.) WxDxH 19x21.9x1.725

Weight 23.3 lbs.

Temperature 0°~40°C operating, -20°~60°C storage

Humidity 20% to 90% non condensing

Power Supply (Standard) 110/220VAC, 50-60Hz

Power Supply (RACKMUX-T15-

48V model only) 36-72VDC

Power Consumption 60W (max), <25W (standby)

Cables Included IEC Power cord (country specific), 1-1/2 foot 15HD VGA,6 foot DB9 female to DB25 male null modem cable

Rack mount kit Included for Sun & most EIA 19” racks

LCD Panel Specifications

Screen size 15.1” visible diagonal

Resolution 800x600

Controls contrast, brightness, auto-adjust, color temperature

Brightness 250cd/m2(Nits)

Contrast 500:1 (typical)

Viewing Angle 140°H / 125°V

Keyboard Specifications

Type 83 key (US) / 84 key (Europe)

Terminal Emulation

Emulations VT52, VT100, VT220, Console ANSI, PC TERM, TVI910+/925, WY-50+, WY-60, WY-100, WY-120, WY-325,

PCG Alpha

Character matrix 7x12 dot matrix in 10x16 cell with 3 dot descenders

Screen size 80x25

Page length 1, 2, or 4 screens (multiple screen page length reduces maximum number of possible telnet sessions)

Cursor Blink or steady, block or underline

Modes Full duplex, half duplex, block mode, half block mode

Color modes 16 foreground and 16 background colors

Communication Ports

Serial port for host connection One DB9M RS232 port

Network port One RJ45 10Base-T Ethernet port

Local printer ports One DB25F Parallel and one DB9M RS232 port

Serial baud rates 50 to 115,200 bps

Data format 7 or 8 data bits with or without parity, 1 or 2 stop bits

Serial handshake XON/XOFF, XPC, and hardware DTR

Communications options Single RS232 server connection, or up to 12 Ethernet telnet sessions to predefined IP addresses. Both serial

and Ethernet connections can not be used concurrently.

Man030 Rev 7/30/2007