22. 01. 18. Leaflet Number 671730 3

The EMC Directive

2014/30/EU

The Low Voltage

Directive

2014/35/EU

XBOXER XBC 75 & 85 (AT Models)

Supply & Extract Ventilation Unit with Heat Recovery

Installation and Maintenance

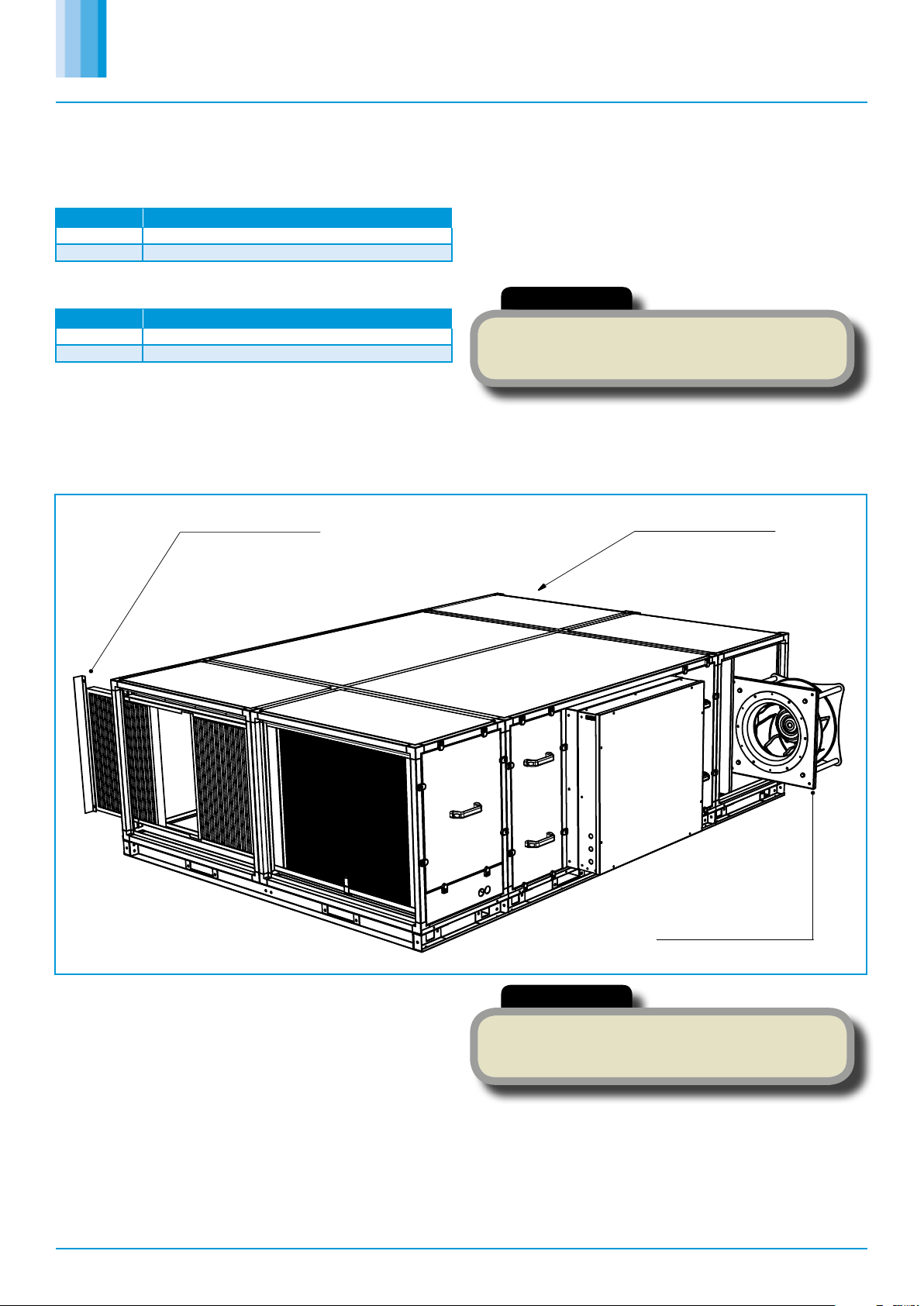

1.0 XBC 75 & 85 Horizontal Ecosmart Adapt

(Trend) (AT) Control Models

The information contained in this document provides details of

installation, operation and maintenance for installers and users of

the XBOXER XBC75 & 85 Supply and Extract Ventilation Units with

Heat Recovery.

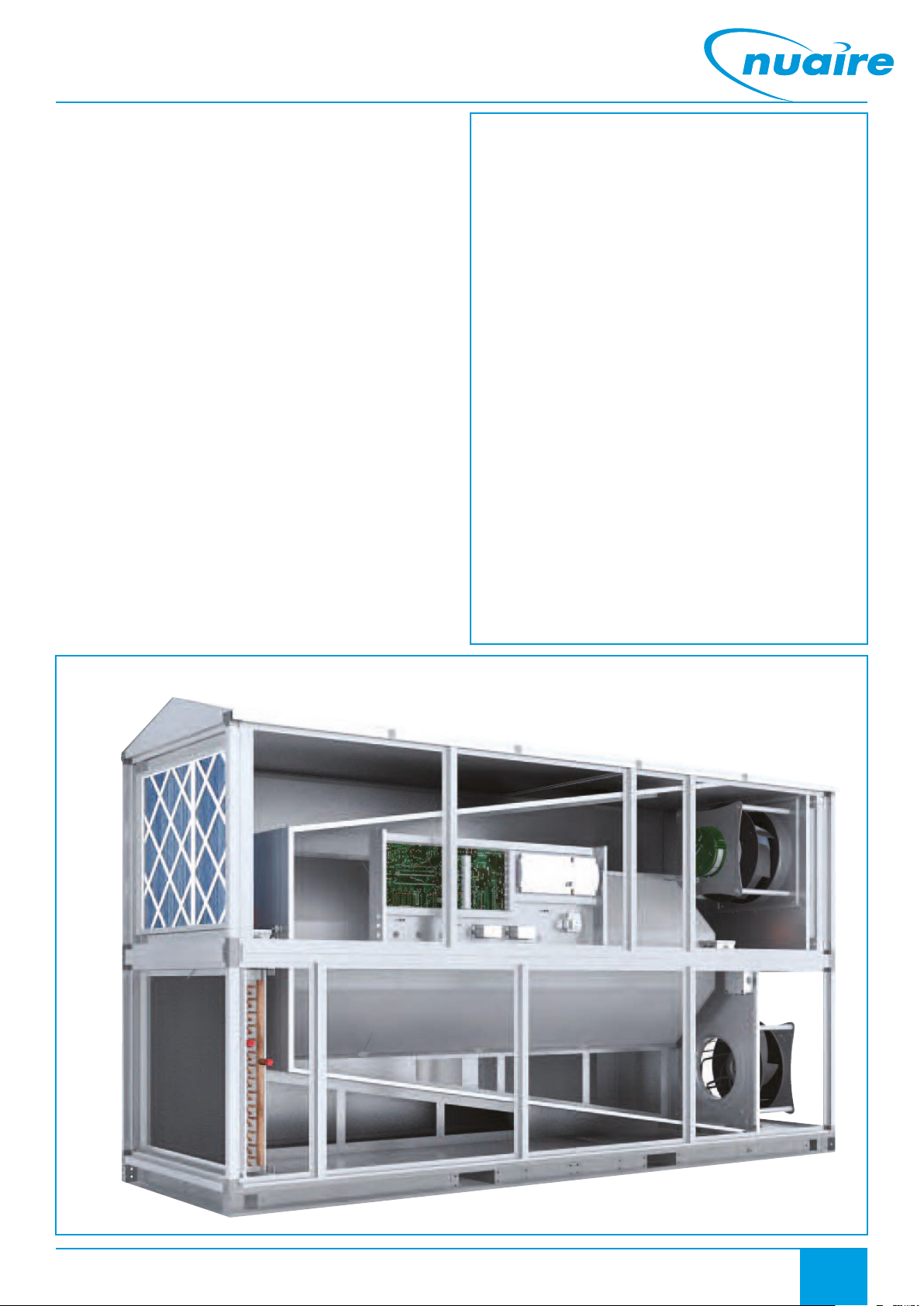

This supply and extract air handling unit range comprises an

combination of high efficiency centrifugal fans with EC motors, a

counterflow design plate heat exchanger, filters, optional heaters

(LPHW and Electric) and a casing with high mass acoustic treatment.

The one-piece ventilation unit shall be constructed with double

skinned Aluzinc panels on an aluminium Pentapost frame with integral

acoustic mineral fibre ensuring low breakout noise levels. The unit

shall incorporate a high efficiency aluminium counterflow plate heat

exchanger matrix with a thermal efficiency of up to 92%, fitted with

a segmented 100% bypass facility and actuator (patent app. for)

operating under automatic control.

A range of matched, side by side internal and external attenuators

(horizontal units) and double deck internal and external attenuators

(vertical units) with a similar construction method to that of the unit is

available.

General information regarding performance and specifications for the

equipment may be obtained from our Technical Literature, and / or

project specific documentation.

Code description: XBOXER XBC Ventilation Unit

XBC 75 - H - LAT - R - WP

| | | | | | |

1 2 3 4 5 6 7

1. XBOXER XBC Range

2. Unit size 75 & 85

3. H = Horizontal Side by Side layout

4. N = No Heater

L = LPHW Heater

E = Electric Heater

5. AT = Adapt (Trend)

6. R = Opposite arrangement

7. WP = Separate Matched Weather Roof if required

Code description: Matched Attenuator

XBC 75 - H - SIL900

| | | |

1 2 3 4

1. XBOXER XBC Range

2. Unit size 75 & 85

3. H = Horizontal Attenuator

4. SIL900 = 900mm Attenuator

SIL900WP = 900mm Attenuator with roof

Figure 1. Layout Overview of the XBC horizontal unit, viewed from

above with lid removed.