2

24. 03. 22. Document Number 671432

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

ES-ISCInstallation Manual

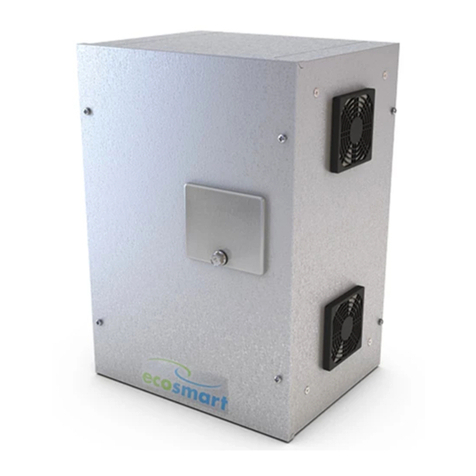

2.0 INTRODUCTION

The Ecosmart Energy Saving Speed Control is designed to control

selected Nuaire fans and to match the range of integrated

Ecosmart control systems.

The control is only available for three phase electrical supply.

The case material is of Aluzinc corrosion resistant steel, incorporates a

frequency inverter, Ecosmart control board and is directly compatible

with the Ecosmart range of user controls, time clocks, ‘stats and

sensors.

3.0 DELIVERY & HANDLING

All equipment is inspected prior to despatch and leaves the factory in

good condition. Upon receipt of the equipment an inspection should be

made and any damage indicated on the delivery note.

Particulars of damage and/or incomplete delivery should be endorsed

by the driver delivering the goods before offloading by the purchaser.

No responsibility will be accepted for damage sustained during the

offloading from the vehicle or on the site thereafter. All claims for

damage and/or incomplete delivery must be reported to Nuaire within

two days of receipt of the equipment.

The weight of the unit modules and palletised items are displayed

on the packaging. Some of the modules have an uneven weight

distribution, and this will be indicated by labelling where appropriate.

Offloading and positioning of the equipment is the responsibility of

the purchaser. Items should only be lifted by competent personnel

following appropriate risk assessment.

Always handle with care to avoid damage and distortion, and where

lifting slings are employed use spreaders to ensure slings do not come

into contact with the unit case, or control pack.

Assembly with

base frame

Palletised

Forklift

Slings via spreaders fitted to unit

with base frame.

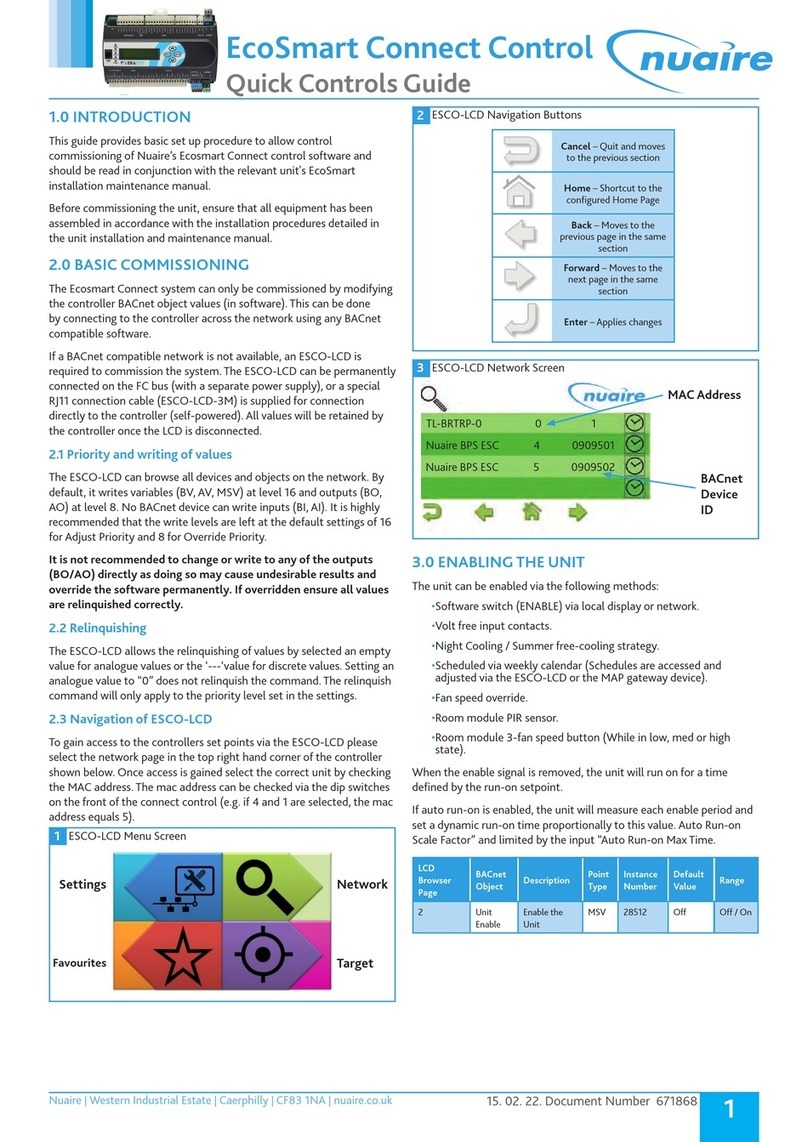

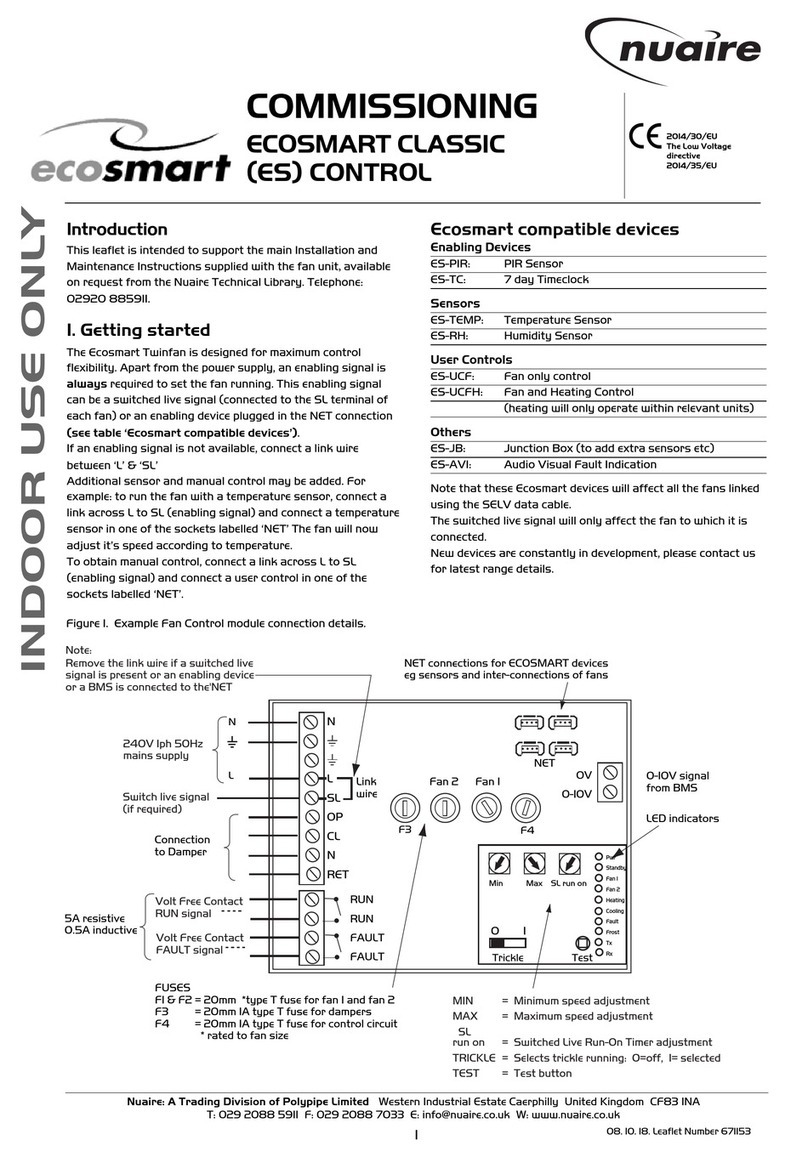

1 Typical Lifting Methods

4.0 DIMENSIONS (mm) & WEIGHTS (kg)

Control sizes are selected by matching the unit full load current with

the control code i.e. control code ES-ISC3.3A is suitable for a fan with a

maximum full load current of 3.3A.

The Inverter overload is pre-set at the rating plate value, if a lower

setting is required fit an appropriately sized overload relay to the output

contactor and adjust accordingly.

E

A

C

D/2

D/2

B

D

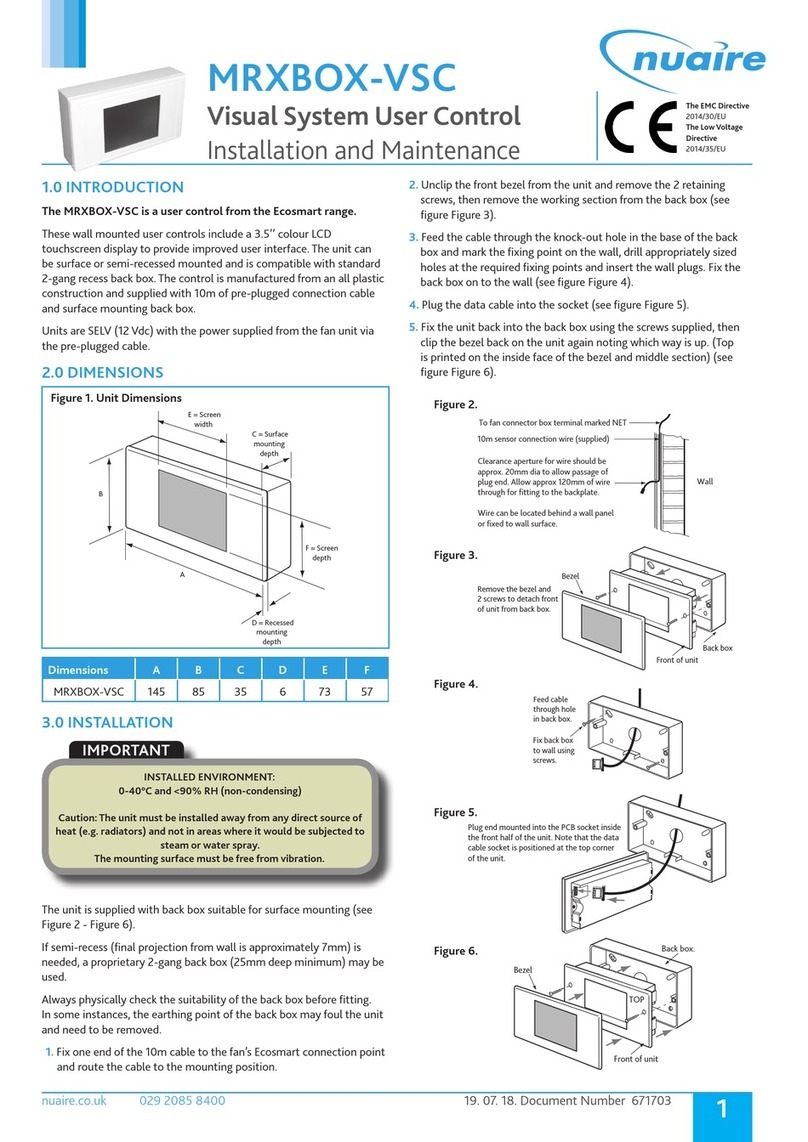

2 Dimensions and Drill Pattern

Unit Code A B C Weight Drill Pattern

D E

ES-ISC1.2A 230 325 410 6 340 298

ES-ISC2.4A 230 325 410 6 340 298

ES-ISC3.3A 230 325 410 6 340 298

ES-ISC4.1A 230 325 410 6 340 298

ES-ISC5.6A 290 390 455 14 470 373

ES-ISC7.3A 290 390 455 14 470 373

ES-ISC8.8A 290 390 455 14 470 373

ES-ISC12.5A 290 390 455 20 470 373

ES-ISC15.6A 290 390 455 20 470 373

ES-ISC23.1A 290 390 455 20 470 373

ES-ISC38.0A 355 525 805 40 710 510

5.0 INSTALLATION

Installation must be completed by competent persons, in accordance

with good industry practice and should conform to all governing and

statutory bodies i.e. IEE, CIBSE, etc.

The ES-ISC is designed to be installed indoors, away from any water

spray or steam generating source. Fix or mount in upright position to a

secure vibration free vertical surface (Figure 2). Ensure the ventilation

grilles are free of obstruction. Minimum distance of 50mm between

grilles and any side obstruction. Minimum distance of 100mm between

grilles and any top obstruction. If the unit is installed outdoors, the

matching size weathering cover ES-ISC-WP(A-C) must be used to

provide weather protection.

The operating range is -10°C to 40°C, up to 85% relative humidity

(non-condensing). Installation in unventilated loft is not

recommended.

Ensure that the unit is electrically isolated from the mains supply

before commencing work. When the fan is isolated, allow 5

minutes for the capacitors in the inverter to discharge before

commencing any work on the unit.

Motors of 4kW and above must be connected to Delta ∆.

The screening of the power cable must be continuous. Bridge any

breaks (e.g. at local isolators) using braided earthing cable. Ensure

the screening is earthed at both ends.