Installation and Maintenance DUCTMASTERBIFURCATED

could be attached to the feet of the fan in order to determine

the ducting centreline relative to the mounting plane.

(Foot fixing centres are shown on fixing details drawing

which should allow the brackets to be pre fitted to the wall

ready to accept the fan assembly).

Consider the position of the fans electrical terminal box

when choosing an installation position.

Assuming that the position for mounting has been chosen.

and any wall brackets (if used) are already correctly located,

stand or support the unit in place and check the unit is

aligned with the ductwork in both horizontal and vertical

planes. A degree of adjustment is provided on the feet but it

may be necessary to pack up the height under the mounting

feet. See fixing details on page 9.

Mark on the floor / structure the fixing positions for the feet

or resilient mountings and if necessary drill suitable holes to

accept bolt or screw fixings (screws not supplied).

If matching silencers are to be installed, these should be

fitted to the fan with any other accessories such as flexible

connectors etc. before installation and the complete assembly

mounted in position using the same procedure.

The matching flanges if required on the installation are

fixed to the ductwork ends with rivets etc. Ensure the

clamping collars have been placed onto the ducting before

drawing the flanges together. Note: make sure the flange

faces are properly mated before fitting and tightening the

clamping collars.

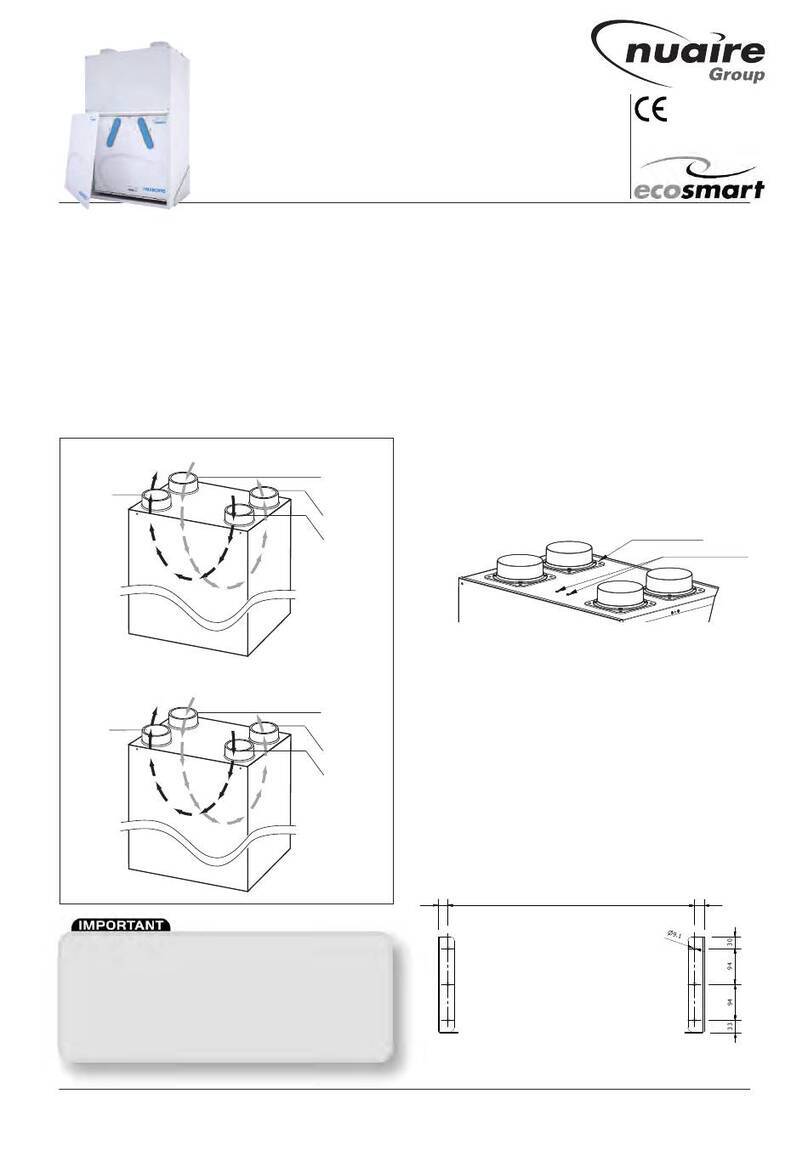

Suspended horizontally or vertically

The only difference for suspension is in the positioning of

the mounting feet which are now fixed to the sides of the

mounting pads by the smaller single hole leg of the feet.

See fixing details on page 9.

If Resilient Mountings are to be included note that the

rubber mountings must remain in compression - this

involves fixing the rubber mounting upside down inside

the foot. The large metal safety washers must be fitted

under the studding nuts on each mounting. See Resilient

Mounting assembly (suspended) drawing on page 6.

General.

Motors are totally enclosed and protected to IP55 (Dust and

low pressure water jets). Motors may incorporate drain

holes to allow any condensation to escape from the motor

casing. It is essential therefore that these drain holes

are positioned at the lowest point of the fan motor

when the unit is horizontally mounted.

All bearings are pre-packed with grease and sealed for life.

3

Handling

The DuctMaster fan impeller is carefully balanced prior

to despatch. Care must be taken on site when handling the

unit not to damage or distort the blades or alter the motor

position. Do not pass lifting slings etc through the impeller.

Always use the mounting pads (top or bottom) for sling

attachments.

The fan is supplied with installation accessories i.e. two

matching flanges, two clamping collars and four mounting

feet attached. These items are fitted before delivery to

ensure parts are not lost on site. If the optional flexible

connectors are specified these will be fitted for delivery to

the customer. However care must be taken when handling

the unit assembly as the flexibles can be distorted or damaged.

Installation

Application

Unit

For external use it is good practice that the unit is installed

so that the motor tunnel is horizontal. Also the unit will be

painted RAL9014 (grey) which is suitable for maximum

temperatures of 230oC.

For internal use it is good practice that the unit be installed

so that the motor tunnel is vertical for a horizontal airflow.

Prior to installation the impeller should be rotated by hand

to check for smooth rotation and that no transit damage has

occurred.

Horizontal on floor etc.

Before commencing work it will be necessary to remove the

clamping collars and loose flanges. Simply unscrew the

clamp nut using a suitable spanner.

Note: during installation, ensure that the flanges are mated

together correctly before tightening the clamps.

The position of the shakeproof washers on the foot

mountings is important as these washers are fitted to restrain

any longitudinal movement of the feet. See fixing details on

page 6 noting that you have a choice of two holes when

fitting the feet for floor mounting.

If the optional resilient mountings have been chosen these

should be attached to the unit feet at this stage. See Resilient

Mounting assembly (floor mtg) drawing on page 6.

Note that the large steel safety washers in the mounting kit

are not required for floor mounting and can be discarded.

Details of resilient mounting kit selection is shown in the

table on the same page.

If the optional wall support brackets are to be used they