Installation and Maintenance OPUS (R range)

2

Installation

a) An opening should be prepared to accept the fan case

plus a clearance of 5 - 10mm which will be necessary to

allow for the fixing brackets. Therefore an area 327mm x

245mm will be required. Care must be taken during this

operation as an aperture larger than 335mm x 253mm

will not be covered by the front panel skirt.

It is assumed that a solid non reverberant mounting posi-

tion has been selected, and the necessary passages for

ductwork, from outlet spigot and to subsidiary inlet

spigot (if a second room is to be ventilated) as well as the

electrical connection prepared. It is also assumed that

compatible ductwork is already installed.

b) Mounting brackets are supplied with all OPUS fans but,

depending on the type of unit, may need to be shortened.

The bracket has a series of notches, one of which is suit

able for your unit. Offer up the bracket to the unit (small

leg of bracket to back of unit) and note the notches which

correspond with the back of the skirt. Using a hacksaw

cut the bracket tolength. Similarly prepare the two

remaining brackets. (Fig. 3).

Attach the three brackets to the large 'Y' shaped plate

using the self tapping screws supplied to form a

mounting frame. (Fig. 4).

Position the mounting frame in the prepared aperture so

that the ends of the three cut brackets are flush with the surface

of the wall. Secure the mounting frame with suitable fixings.

c) Unclip and remove the fan module from the case.

Knock out a suitable cable entry hole in the rear face of

the case.

If a second room is to be served remove the appropriate

weakened area from the case, and, working from the

inside fit the subsidiary inlet spigot by passing it through

the case and turning it one quarter of a turn to lock in

position, see fig. 5.

Fig.3. Selecting bracket length.

Fig. 4. Mounting frame assembly.

Fig. 5. Fitting a subsidiary spigot (supplied in optional kit)

d) Offer up the casing to the mounting frame feeding the

supply cable through the entry hole. Engage the outlet

spigot(s) in the ductwork and fix the casing to the frame

using the three screws supplied.

e) Connect the wiring to the internal terminal block/socket.

f) Fit the fan module to the case, mating it's plug fully with

the internal socket. Secure in position with the two spring

clips.

g) Re-fit the cover using the 4 screws provided. Fit the fiters

into the front cover panel rebates. NOTE: If a subsidiary

spigot kit is employed the Balancing Plates included can be

inserted under the filters to adjust the extract from the

rooms.Test / run the unit.

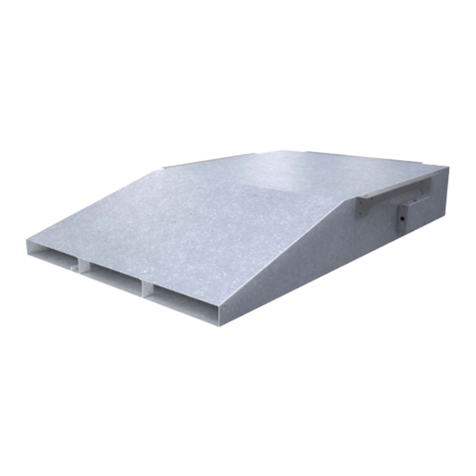

Fig. 6. Flatduct installation

Installing the unit into flatduct.

It is assumed that the flatduct is already fitted with a plenum

section incorporating a 100mm dia. spigot in the area of the pro-

posed extract fan.

a) Proceed as in steps (a), (b) & (c) above.

b) Feed the 100mm flexible ducting (supplied) through the

rear of the mounting frame and fit to the spigot on the

flatduct plenum.

c) Offer up the casing to the mounting frame and join the

other end of the flexible ducting to the outlet spigot using

tape (not supplied). Fig. 6.

Feed the electrical supply cable through the entry hole and

fix the case to the mounting frame using the three screws

supplied.

Continue as in (e) to (g) above.