2

In the event of a breakdown contact

your Numatic dealer or the

Numatic Technical

help line +44 (0)1460 269268

Machine Overview ................................. Pages 2-3

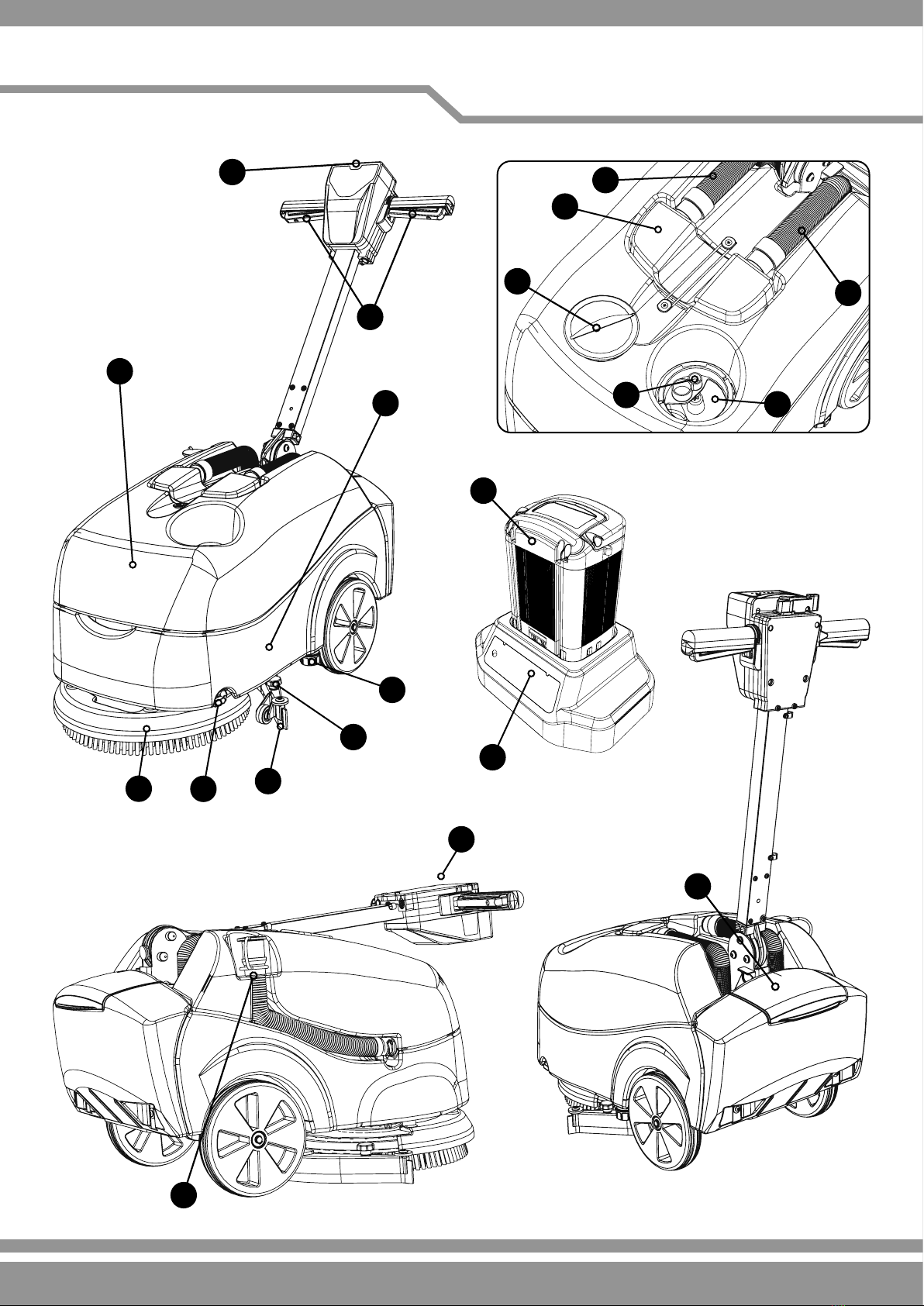

Control Panel Overview ................................. Page 4

Quick Set up Guide ................................. Page 5

Machine Set up Guide ................................. Page 6-7

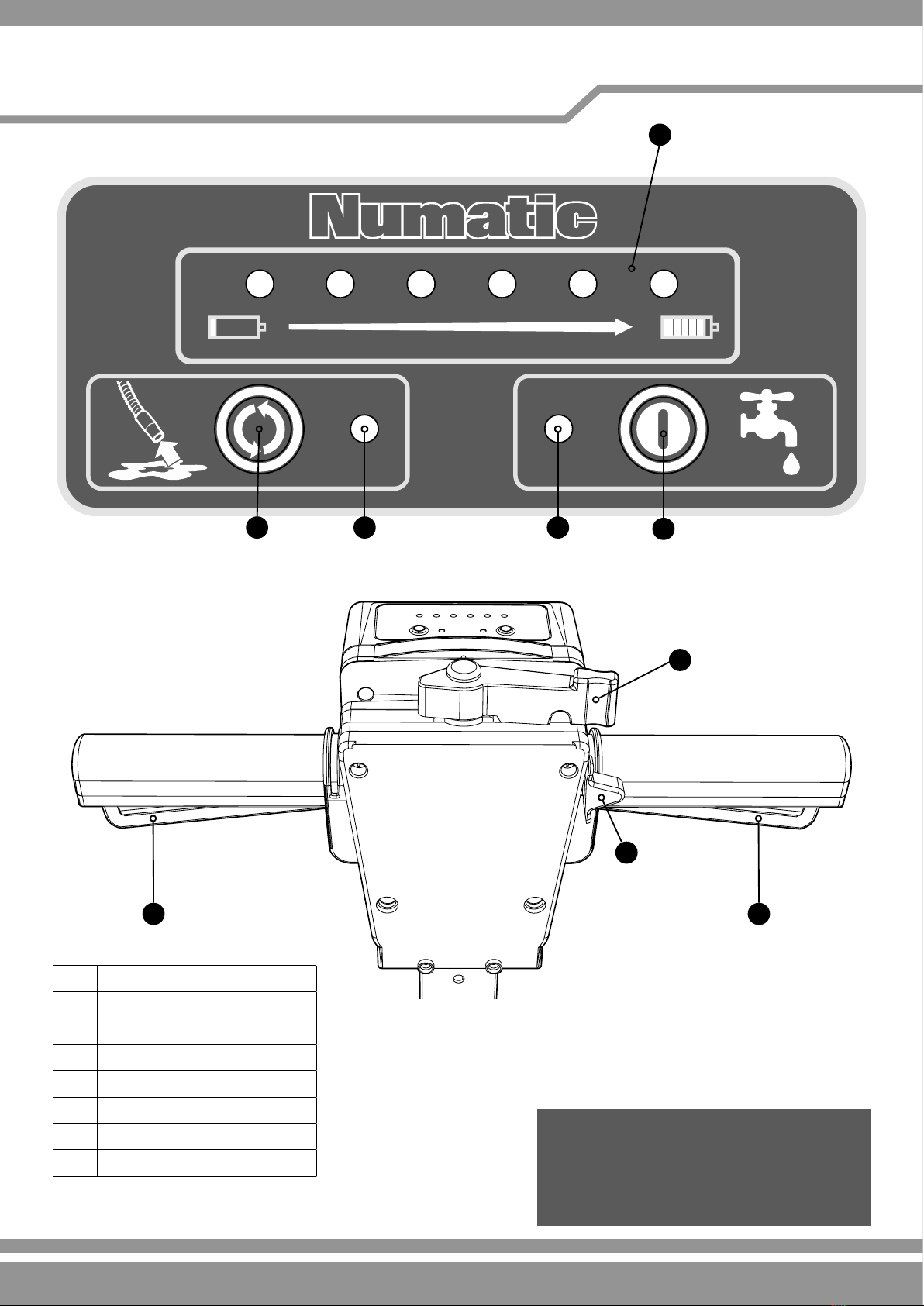

Fitting the Brush / Pad ................................. Page 6

Fitting the Floor-tool ................................. Page 6

Filling the Clean Water Tank ........................... Page 7

Fill Level Indicator ............................... Page 7

Water Flow Adjustment ................................. Page 7

Machine Operation ................................. Pages 8-9

Setting the Cleaning Controls ......................... Page 8

System Error Indicators ................................. Page 8

Raising/Lowering Floor-tool.............................. Page 9

Machine in Use ................................. Page 9

Regular Maintenance ................................. Page 10

Emptying Top/Bottom Tank............................... Page 10

Separator ................................. Page 10

Changing Floor-tool Blades ............................. Page 11

......................... Page 11

Lifting the Machine ................................. Page 12

Specications ................................. Page 13

Trouble Shooting ................................. Page 13

About the Machine ................................. Page 14

Rating Label / PPE / Recycling ....................... Page 14

Twintec Maintenance ................................. Page 14

Information for Scrubber Dryer .................... Page 15

Battery Information ................................. Pages 16-19

Recommended Spare Parts ............................. Page 19

Schematic Diagram ................................. Page 20

Warranty ................................. Page 21

EU Declaration Document ........................... Page 22

Company Address ................................. Page 24

Index

After the removal of all the packaging,

carefully open and check the contents

●Owner Manual

• Battery & Charger Manual

●Battery Charger & Lead

●Battery●Scrub Brush

●Squeegee Assembly

PLEASE READ

BEFORE COMMENCING

OPERATION.

KEEP FOR FUTURE REFERENCE

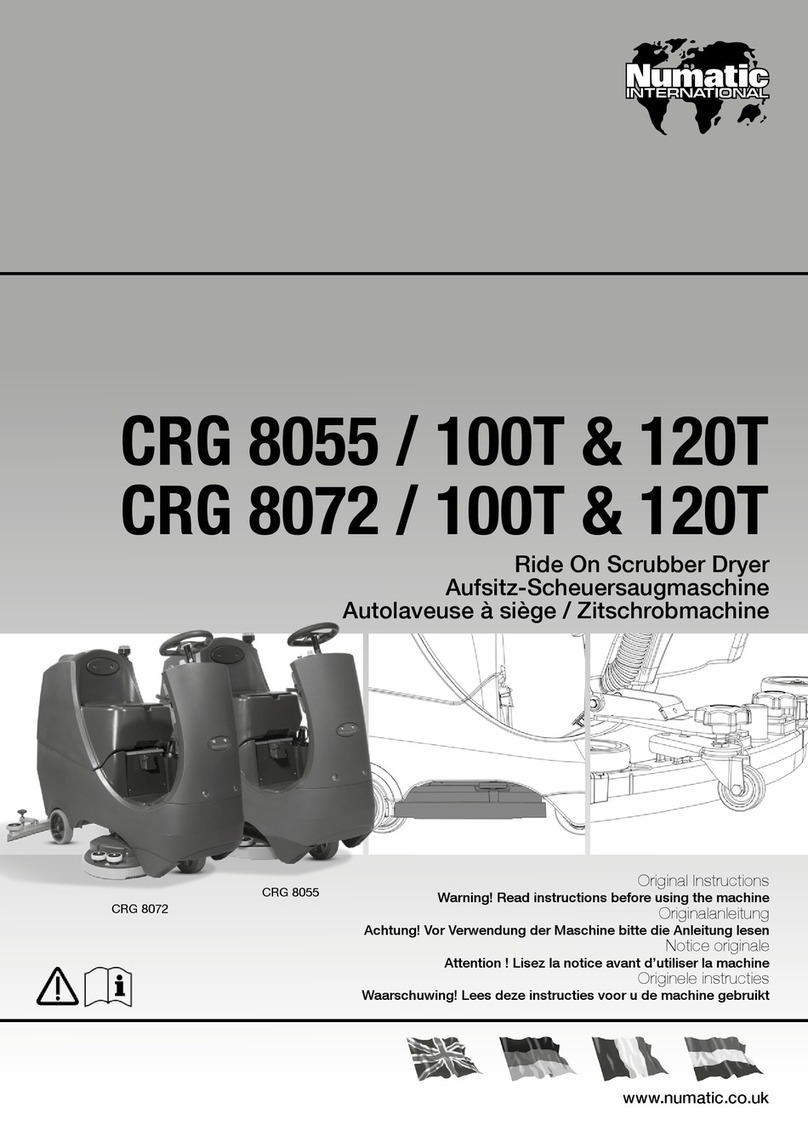

Machine Overview

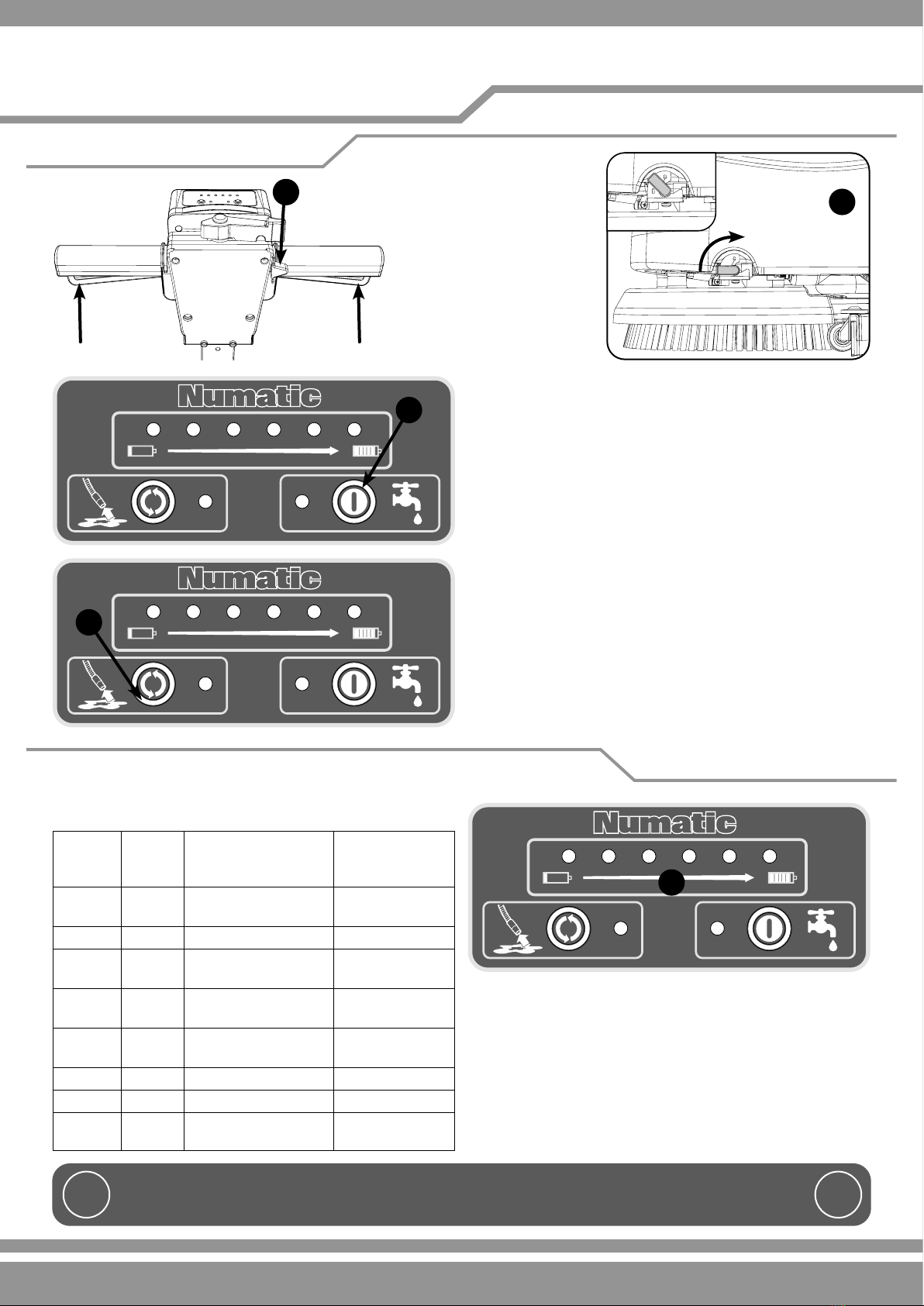

1Operator control panel ( see page 4 )

2Triggers

3Waste-water tank

4Clean-water tank

5Brush deck

6Squeegee blades

7Floor-tool retaining knobs

8

9Clean-water emptying cap

10 Floor-tool vacuum hose

11 Vacuum hose

12 Separator

13

14 Clean-water level indicator

15

16 Start Switch

17 Top tank (waste water) drainage hose

18 Battery compartment

19 Battery

20 Battery charger