54 JUMBO LIFT 3200 NT - HYMAX XX 3200 PH 19.05.2015 AD H9402

4 Assembly and commissioning

4.1 Set up guidelines

Lift set up is done by trained manufacturer per-

sonnel or a contract partner. If the operating

company has appropriately trained assemblers,

the system can also be set up by them. Set up is to

be done according to the assembly instructions.

A standard system may not be set up in explosion

endangered spaces or wash halls.

foundation or make it according to the guidelines

in the foundation plan. The set up location must

be level and even. Foundations in open air and

spaces where winter storms or frost are to be ex-

pected, must have a foundation to frost depth.

The operating company is solely responsible for

the set up location.

+ PE, 400 V, 50 Hz, fuses with 16 A, slow. The con-

nection point is on the operating unit.

To protect the electrical cable all cable conduits

-

tic pipes.

commissioning, the operating company must

have the lift grounding conductors inspected on-

insulation resistance test is also recommended.

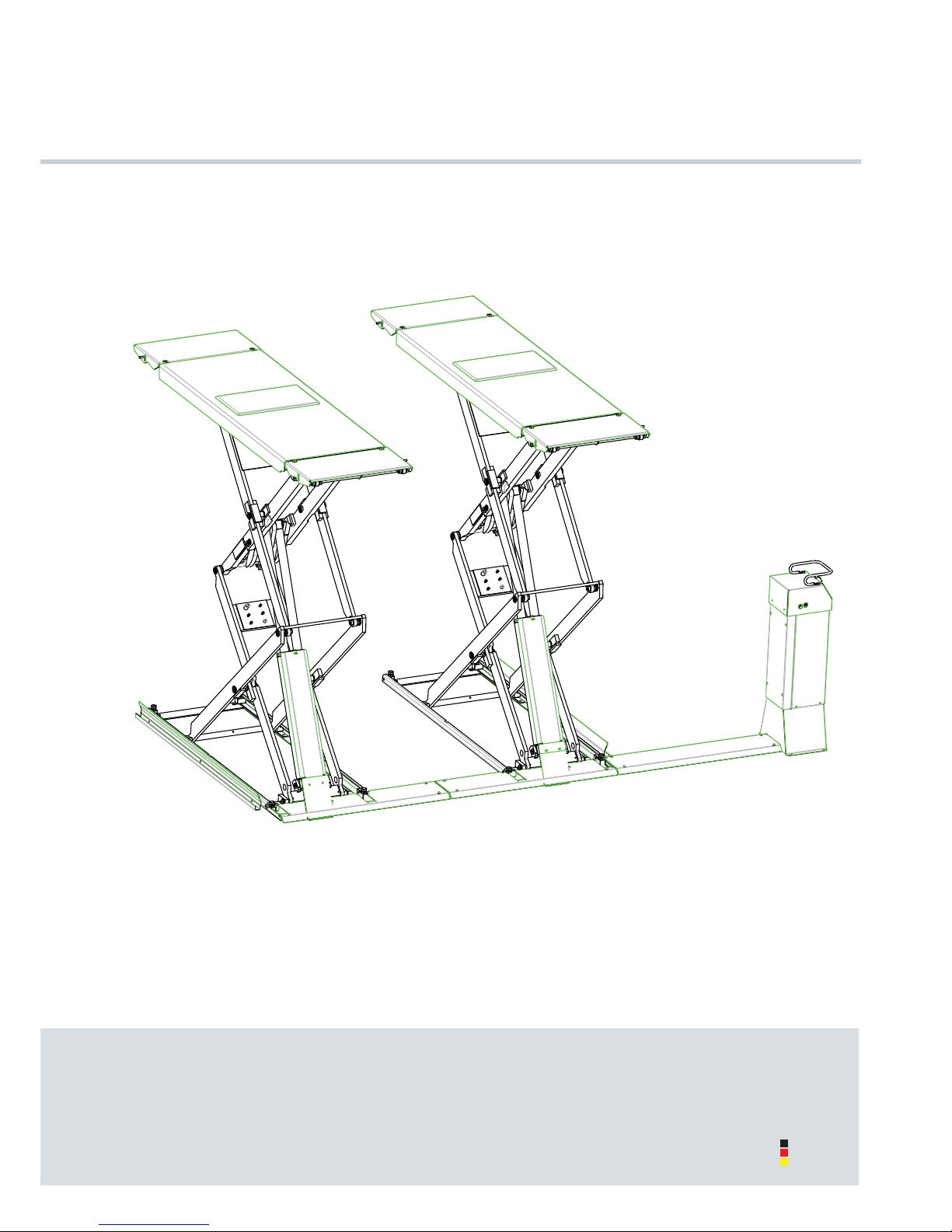

4.2 Setting up the lift

Before setting up the lift, ensure that everything

possible is done to prevent accidents due to care-

less assembly. This includes, above all, the use of

-

Carefully remove the lift from the wooden crate

and check for damage.

Position the lift according to the data sheet at the

desired set up location.

Set up the unit, connect power supply.

iThe set up location of the operating unit can be

selected from two variants. Either in the drive-in

direction at the front right or left.

Fill with hydraulic oil, the manufacturer recom-

mends a high value hydraulic oil with a viscosity of

32 cst. The required oil volume is approx. 14 litres.

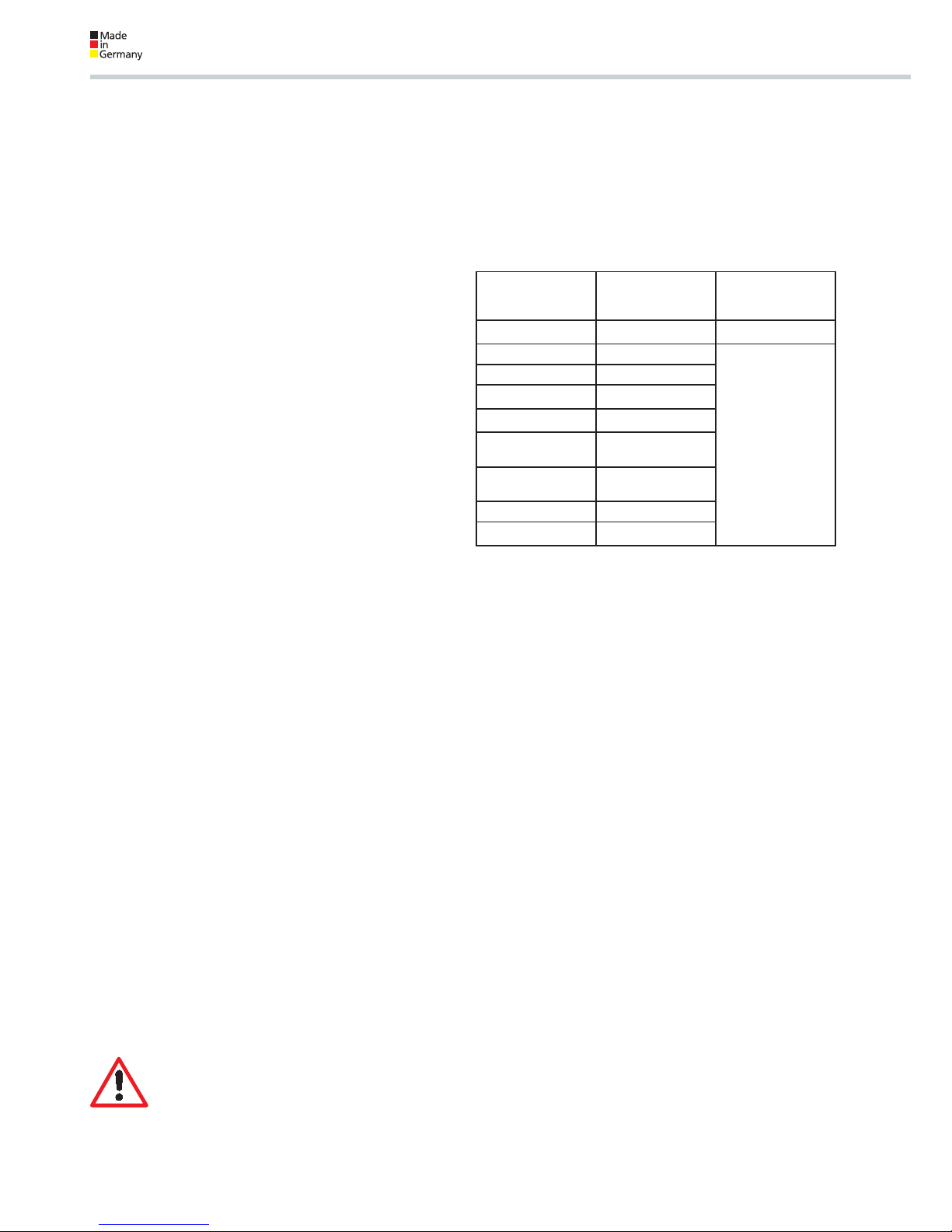

12 A1 13 A2

14 N1 15 N2

Move the lifting upwards to approx. 1,500 mm

Check the alignment of the base plates again

to be placed through the holes in the base plates.

Clean the bore holes by blowing them out with

air. Insert safety anchors into the holes.

The manufacturer recommends using approved

safety anchors and to follow anchor manufac-

turer's instructions.

Before anchoring the lift, check whether the con-

-

chor length from the anchor manufacturer's data

the weight bearing concrete, the thickness of this

covering must be determined.

13 12

14 15

11