www.NutrichefKitchen.com www.NutrichefKitchen.com

PART THREE: TROUBLE SHOOTING GUIDE

1. Faucet Leakage:

Solution: Please screw out and remove the faucet and

install again, make sure the faucet matches the connection

of spear tightly.

2. SpearCross-bar Leakage:

Solution: There is a nut under spear main body, tighten the

nut to prevent leakage.

3. Too Much Foam:

Solution: Flow-control block would help to reduce the

speed of beer owing and reduce amount of foam.

If there is too much pressure, please pull on the pressure

relieving ring for a couple of seconds.

When pressure within keg reach 30PSI, the pressure

relieving ring would release C02 automatically to keep safe.

4. C02 Leakage:

C02 capsule should be installed properly and

tightly. In case there is C02 leakage, please observe the

position of leakage and continue with the tightening

process, but never screw out if gas remains.

PART FOUR: WARNING

1. Keep away from children under 18.

2. Never point cylinder towards someone's face.

3. Do not heat over 140°F as rupture may occur!

4. Discontinue using of this equipment if unsolvable leakage

or visible damage is found.

5. Capsule end become punctured when turned into

regulator base. Unscrewing capsule before it's empty can

result in loss of high pressure gas. Please remember, never

unscrew the C02 capsule before gas used up, liquid C02

spray onto unprotected skin may cause freezing burns.

6. Exterior of capsule may become frozen when in use, this is

normal. But don't touch with bare hands, your ngers

could stick to the frozen surface and cause frostbite.

7. Please ship via land or sea shipment, never bring C02

capsule when you travel by air.

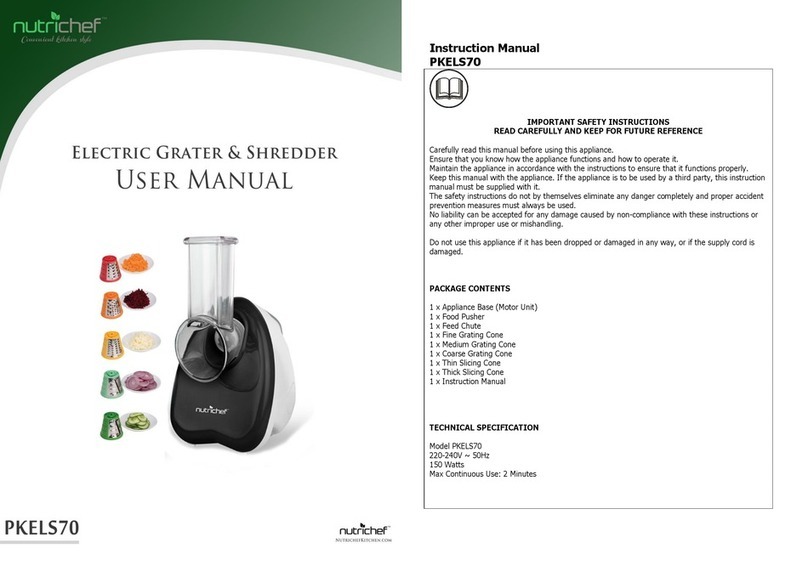

Features

• Complete Stainless Steel Mini Keg System

• CO2 System Keeps Homebrew Fresh & Carbonated All Day

• Solid Stainless Steel Construction Keep Beverage Colder Longer

• Made of Food Grade S/S 304 Rust Proof Stainless Steel

• With Neoprene Sleeve

• CO2 Safety Pressure: 30 PSI

PKBRTP50

64 Oz Stainless Steel Complete Set Dispenser & CO2 System

Weight: 4.1 lbs.

Dimesions: 13.4 x 7.5 x 6.9 inches

PKBRTP100

128 Oz Stainless Steel Complete Set Dispenser & CO2 System

Weight: 4.80 lbs.

Dimesions: 19.5 x 7.5x 6.9 inches

3. Pull on the pressure relieving ring for a

couple of seconds. If the keg was

shaken in transit or warmed, it may

contain excessive pressure which must

be relieved before tapping. A hissing

noise is expected.

4. Slowly turn the regulator knob in

clockwise direction to 5 PSI, and stop

for 2 seconds and turn o regulator.

Wait for 2 mins, then pull on the pressure relieving ring

for a couple of seconds. This is for adjusting pressure of

keg beer.

5. Put a glass or pitcher under the faucet spout,with the

faucet knob pulled forward (ON), slowly turn the regulator

knob on in clockwise direction, until beer starts to ow

out. Don't continue adding pressure,suggest tapping 5-8

PSI(max pressure 30PSI), so please stop turning the

regulator knob when the pressure is enough to tap beer

out with perfect foam. Too much pressure would cause

over foam. When the beer stopped or ow slower, try

turning the regulator knob on slowly, to get bigger

pressure.

6. When you nish tapping, please turn regulator knob to

OFF position.

7. If no beer ow out,then the C02 capsule needs to be

replaced, unless no beer is rema ined. (Normally,16g

capsule can tap 4-5 liters of beer).

Caution: Removing a punctured capsule from regulator

should be done slowly. Swish is expected if pressure

remains.

8. Turn the regulator knob o

and install a new capsule into

the regulator by following

above steps