Pro Trio Analyzer Manual

Page 3

NUVAIR www.nuvair.com

Table of Contents

Introduction ................................................................................................................................................5

1.0 System Description .......................................................................................................................6

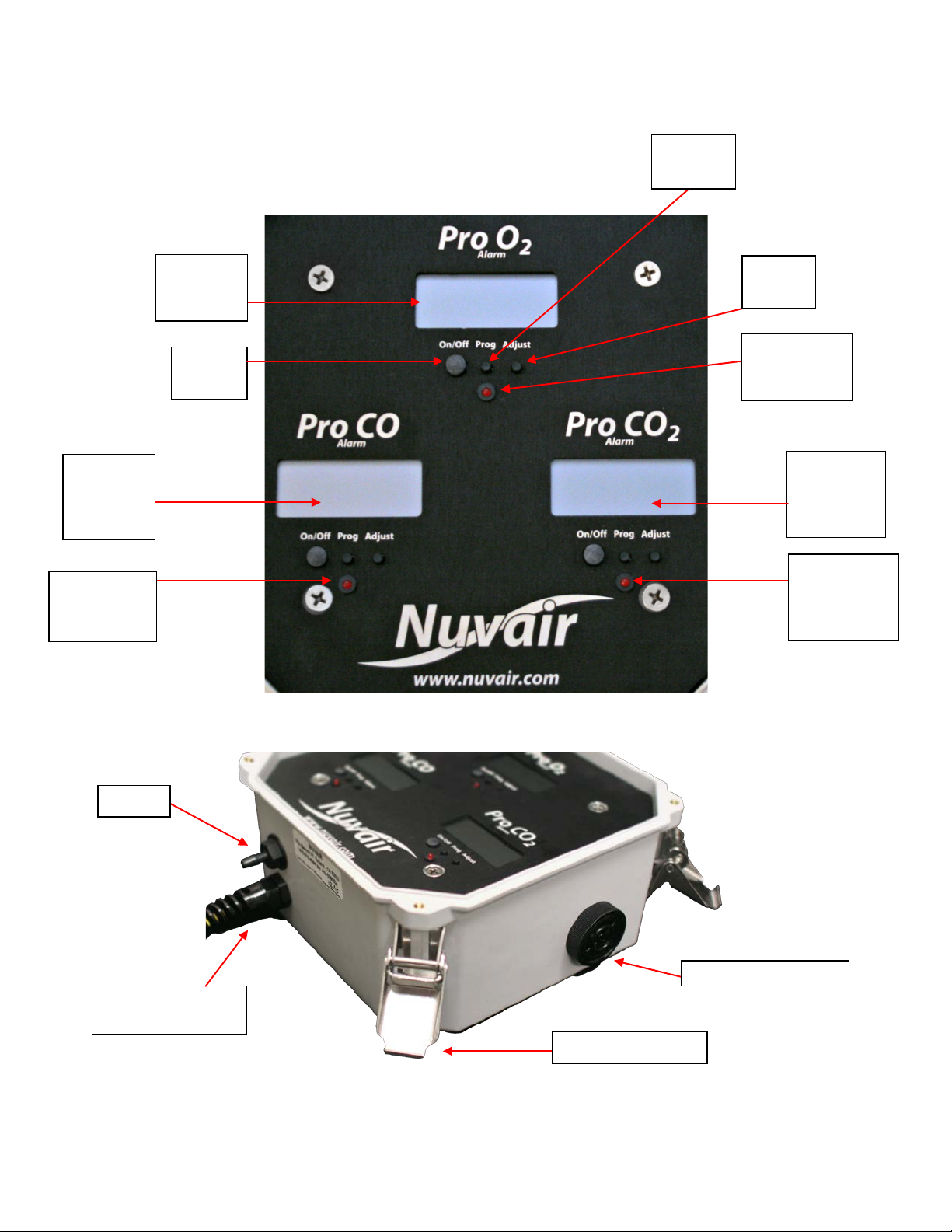

1.1 Identification of Analyzer Components...........................................................................................7

2.0 Individual Specifications of the Analyzers..............................................................................9

2.1 Oxygen Sensor:................................................................................................................................9

2.1 Carbon Monoxide Sensor:...............................................................................................................9

2.2 Carbon Dioxide Sensor: ...................................................................................................................9

3.0 Requirements for Operation of Analyzer Trio......................................................................10

3.1 Gas Flow ........................................................................................................................................10

3.2 AC Power .......................................................................................................................................10

3.3 Gas Sensors....................................................................................................................................10

4.0 Calibration......................................................................................................................................11

5.0 Operation of Analyzer Trio ........................................................................................................12

5.1 Turning on Analyzers:....................................................................................................................12

5.2 Threshold Alarms...........................................................................................................................14

Each Analyzer has independent threshold alarms that are user programmable....................................14

5.3 Powering off ..................................................................................................................................14

Hold down the On/Off button for a couple of seconds on each of the analyzers in the Analyzer Trio.

The Analyzer will display “OFF” and then go blank. ................................................................................14

6.0 Factory Reset................................................................................................................................14

7.0 Maintenance ..................................................................................................................................15

7.1 Analyzer Care.................................................................................................................................15

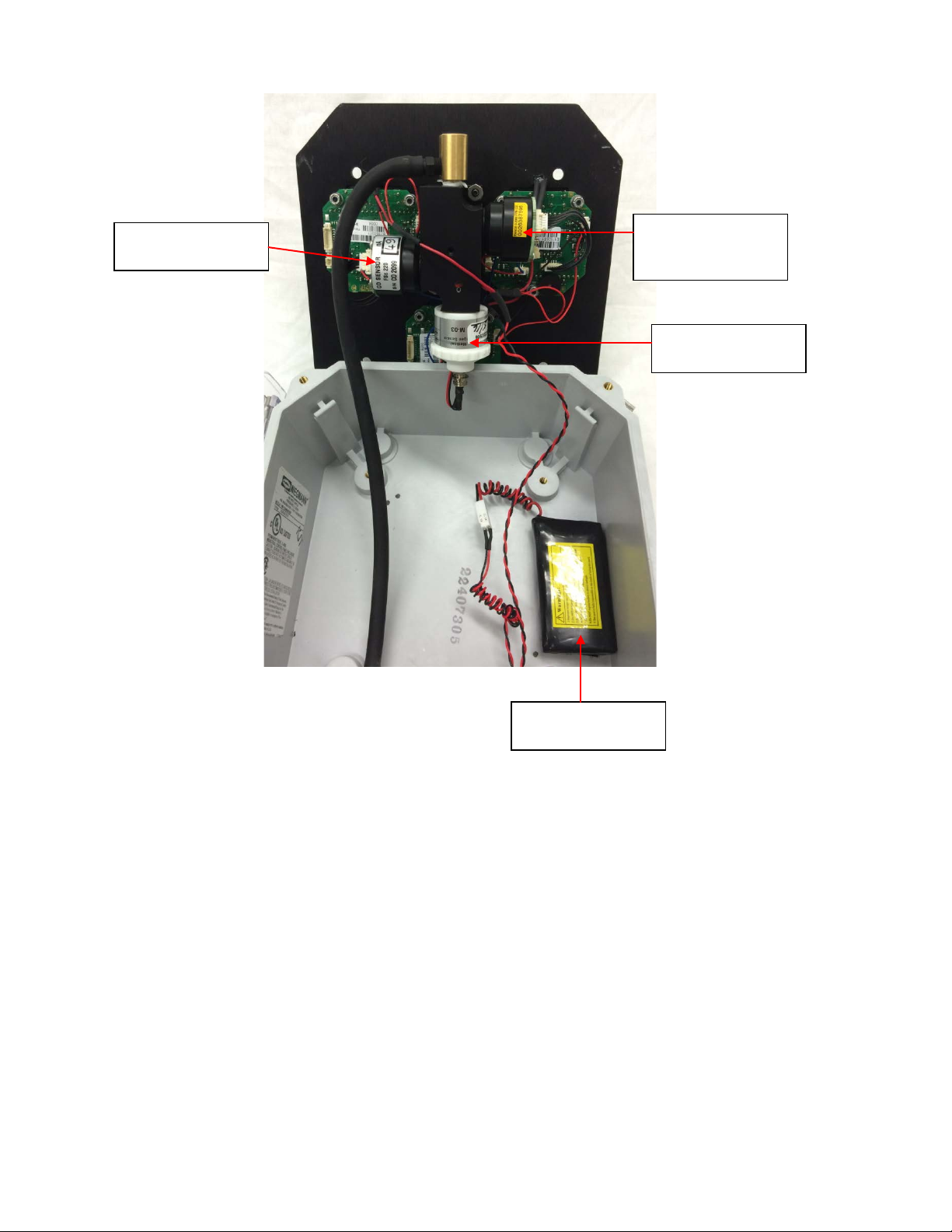

7.2 Battery Replacement.....................................................................................................................16

7.3 Sensor Replacement......................................................................................................................16

8.0 Programming of the Analyzers in the Analyzer Trio ..........................................................16

9.0 Pro O2Alarm Analyzer................................................................................................................17

9.1 Pro O2 Analyzer Controls ...............................................................................................................18

9.2 O2Analyzer Alarm .........................................................................................................................18

9.3 O2Analyzer Sensor ........................................................................................................................18

9.4 Pro O2Calibration Methods ..........................................................................................................19

9.5 Pro O2 Analyzer Operation............................................................................................................20

9.6 Programming Procedures..............................................................................................................21

9.7 Alarm Setting (AL 1 & Al 2) ...........................................................................................................22

9.8 Full Scale Value Setting (FSC) ........................................................................................................22

9.9 Calibration Oxygen Value (O2c) ....................................................................................................22

9.10 Threshold Alarms.......................................................................................................................23

9.11 Powering on and warming up....................................................................................................23

9.12 Powering Off ..............................................................................................................................24

9.13 Factory Reset .............................................................................................................................24

10.0 Pro CO2Carbon Dioxide Analyzer .......................................................................................24

10.1 Pro CO2Controls ........................................................................................................................25

10.2 Pro CO2Display ..........................................................................................................................25

10.3 Pro CO2Alarm ............................................................................................................................26

10.4 Pro CO2Sensor...........................................................................................................................26

10.5 Pro CO2Calibration ....................................................................................................................26

10.6 Pro CO2Operation .....................................................................................................................27