QB OWNER’S MANUAL ABOUT YOUR QB

NU-VU®FOOD SERVICE SYSTEMS MENOMINEE MICHIGAN 49858-1029

(906) 863-4401 ♦ (800) 338-9886 Sales Fax (906) 863-5889 ♦ Service Fax (906) 863-6322 page 1

ABOUT YOUR QB

The NU-VU®QB is an electrically powered and operated commercial baking/cooking appliance. It does not

require exterior venting under normal circumstances; however, hood and venting requirements vary from country

to country, state to state, and even from locality to locality. For this reason, NU-VU®cannot give specific detailed

information regarding your individual application. Your local building inspector, licensed contractor, or installer is

best qualified to determine your specific needs.

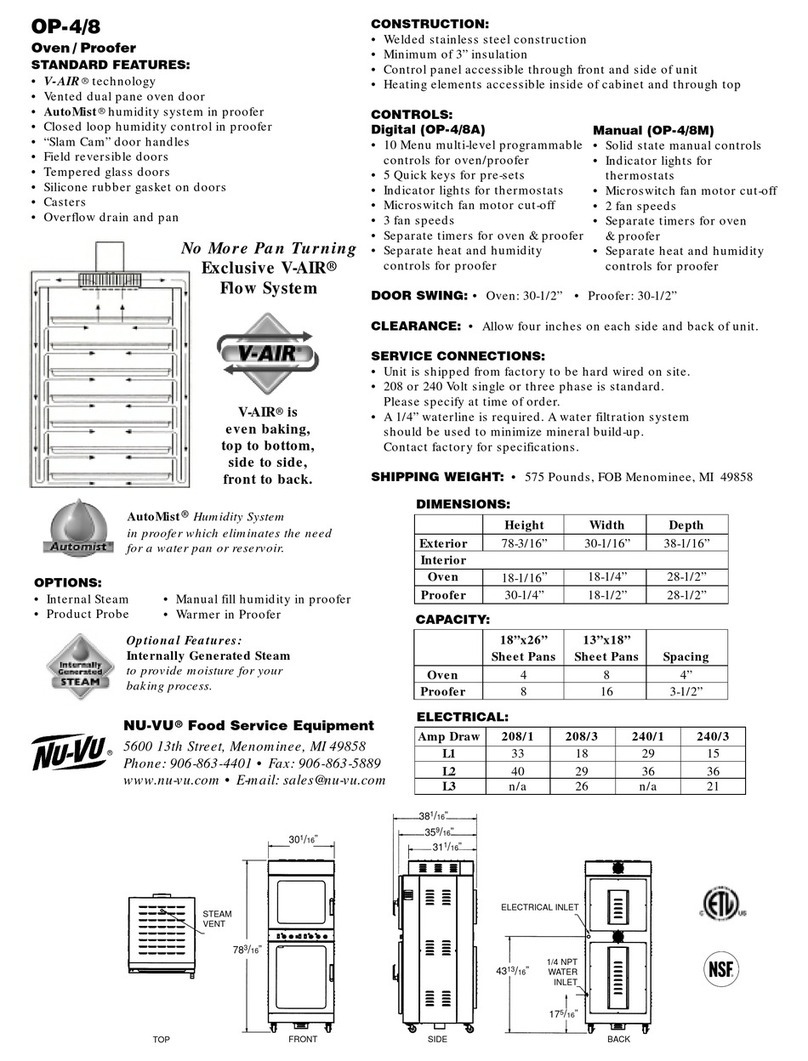

The oven section of the QB features our patented V-AIR®air movement system. A top-mounted blower moves the

air down through the side walls to be heated, then out through specially designed hole patterns to provide even

heat distribution throughout the oven. Your product is baked evenly from top to bottom, side to side, front to back

without turning pans. You can load the oven completely with pans having the same product, bake, and remove the

entire load at the same time. The bake is uniform because each shelf now receives essentially the same air pattern.

It is constructed of stainless steel both inside and out. The front and back frames are cut from single sheets of

stainless steel. Components such as temperature and humidity controls, timers, switches, motors, heating elements,

and others are thoroughly tested before shipment. Ongoing research and development projects are used to

introduce the latest and most dependable components.

The NU-VU®QB is designed for:

•Automatic pan positioning •Dependability

•Rapid and even baking •Low energy consumption

•Easy cleaning •Low maintenance

•Simple operation •Rapid servicing

The AUTOFILL option eliminates the manually filled water pan in the proofer, but requires connection to a

pressurized potable water supply. The immersible element in the AUTOFILL water pan distributes humidity

evenly throughout the proofer compartment to provide the controlled humidity necessary for proper proofing

action.

IMPORTANT: This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning use of

the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.