2|ni.com |NI PXIe-4353 and TC-4353

Contents

What You Need to Get Started ................................................................................................. 3

Installation ................................................................................................................................3

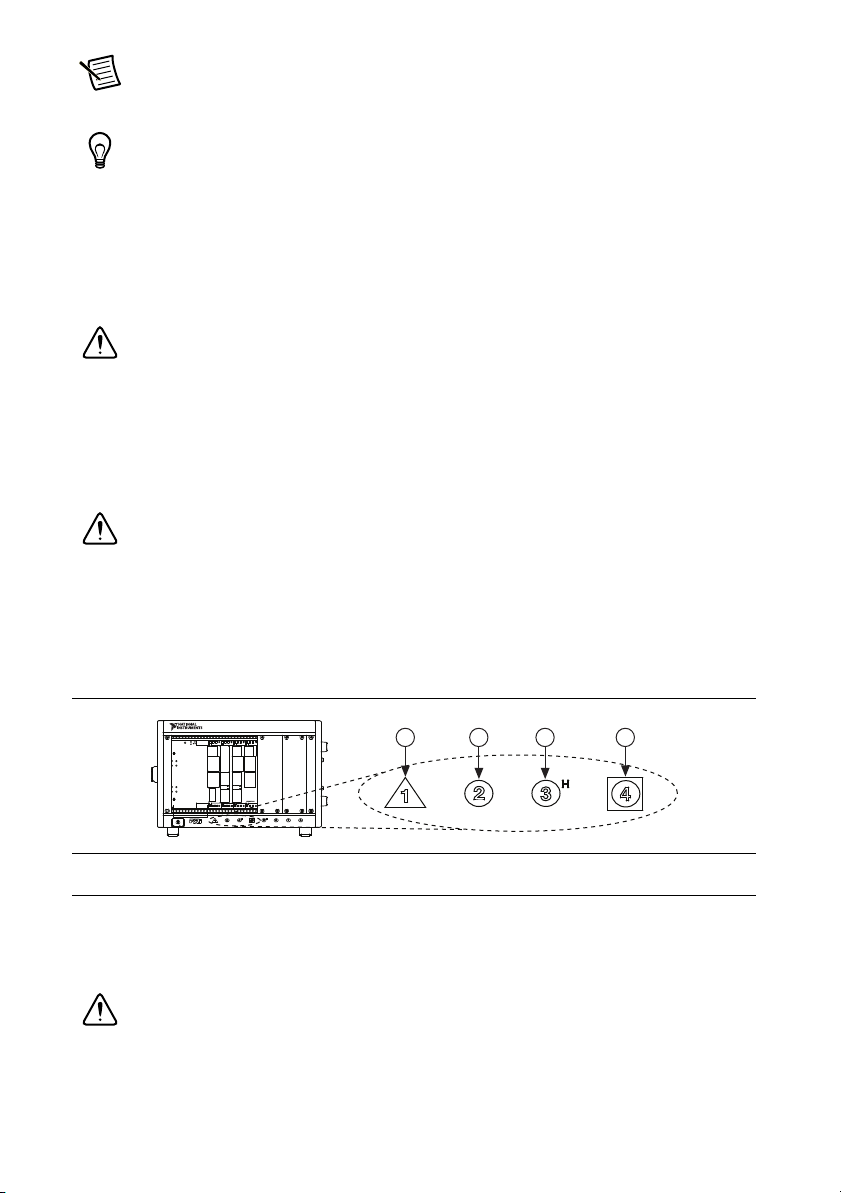

Step 1. Install the Software ...............................................................................................3

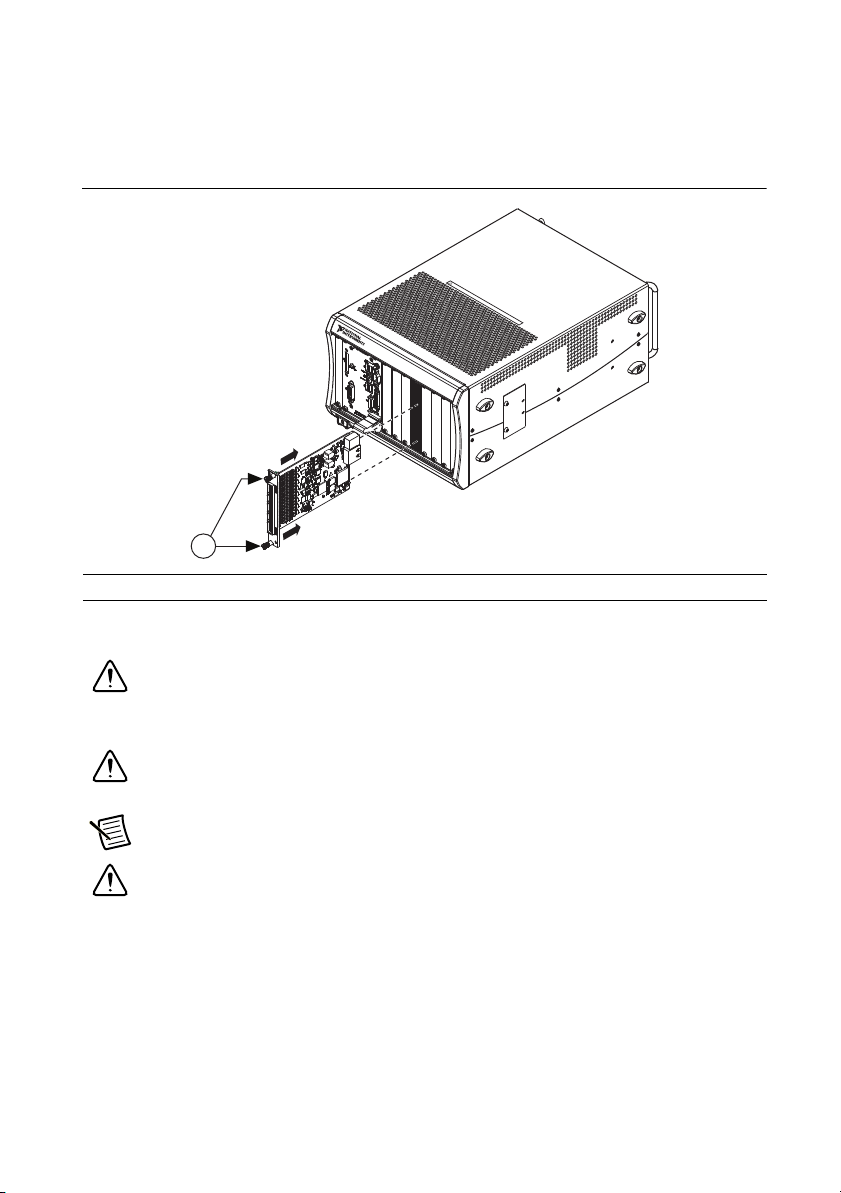

Step 2. Unpack and Install the Module............................................................................. 4

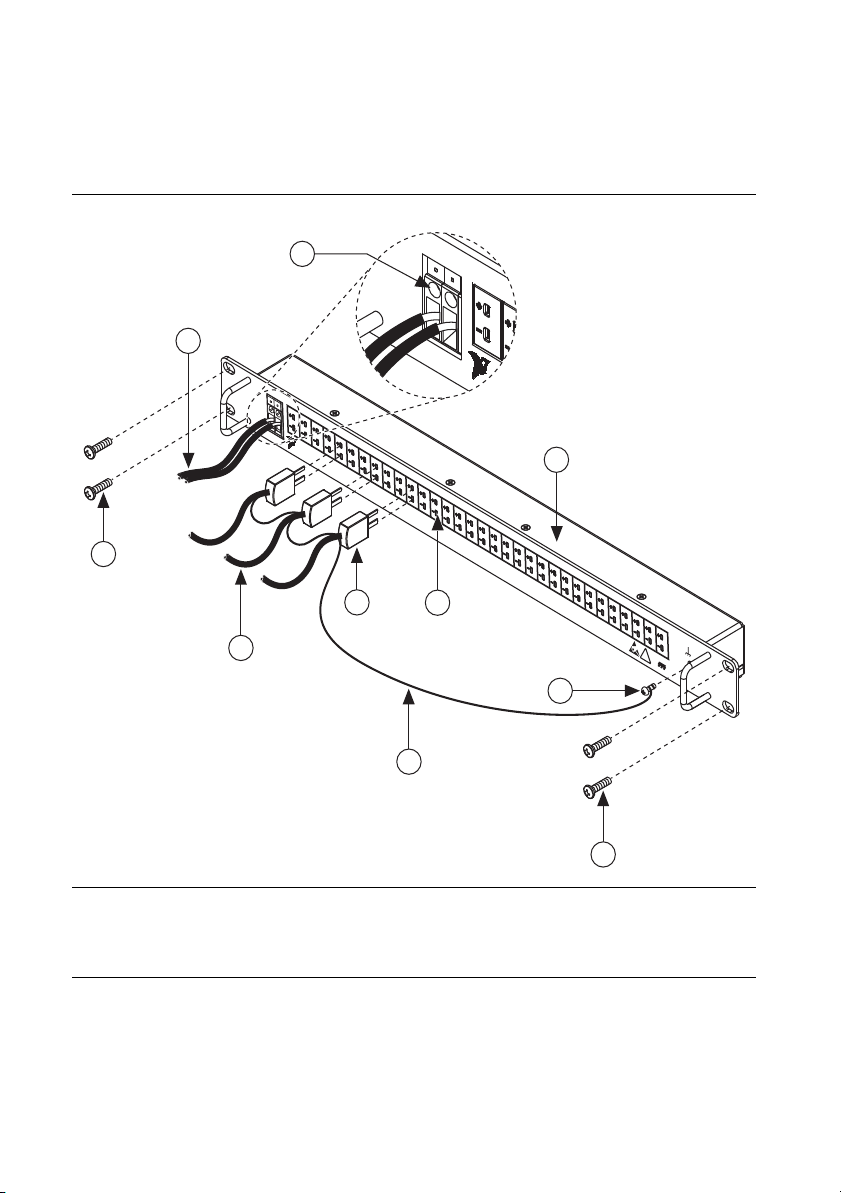

Step 3. Install the Terminal Block, Chassis, and Cables .................................................. 5

Step 4. Confirm NI SC Express Module Recognition ...................................................... 9

Step 5. Run Test Panels .................................................................................................... 10

Step 6. Take an NI-DAQmx Measurement ...................................................................... 10

NI-DAQmx Channels and Tasks .............................................................................. 10

Configure a Task Using the DAQ Assistant from MAX.......................................... 10

Step 7. Use Your NI SC Express 4353 in an Application ................................................11

Programming Examples............................................................................................ 11

Removal .................................................................................................................................... 12

Step 1. Remove the Terminal Block and Cables ..............................................................12

Step 2. Remove the Module..............................................................................................12

Create a Simulated Device........................................................................................................13

Cold-Junction Compensation....................................................................................................14

Minimizing Thermal Gradients ........................................................................................15

Calibrate the Module and Terminal Block ...............................................................................15

More Information......................................................................................................................16

Troubleshooting ................................................................................................................ 16

Specifications............................................................................................................................ 16

Calibration ........................................................................................................................16

Electrical ...........................................................................................................................16

Mechanical........................................................................................................................18

Physical .............................................................................................................................18

Environmental Specifications ...........................................................................................18

Operating Environment............................................................................................. 18

Storage Environment ........................................................................................................19

Shock and Vibration .........................................................................................................19

Safety Voltages .................................................................................................................19

Safety Standards ............................................................................................................... 20

Electromagnetic Compatibility ................................................................................................. 20

CE Compliance ................................................................................................................. 20

Online Product Certification.............................................................................................21

Environmental Management.............................................................................................21

Worldwide Technical Support ..................................................................................................21