IP9032_A Page | 3 © 2022 nVent All Rights Reserved

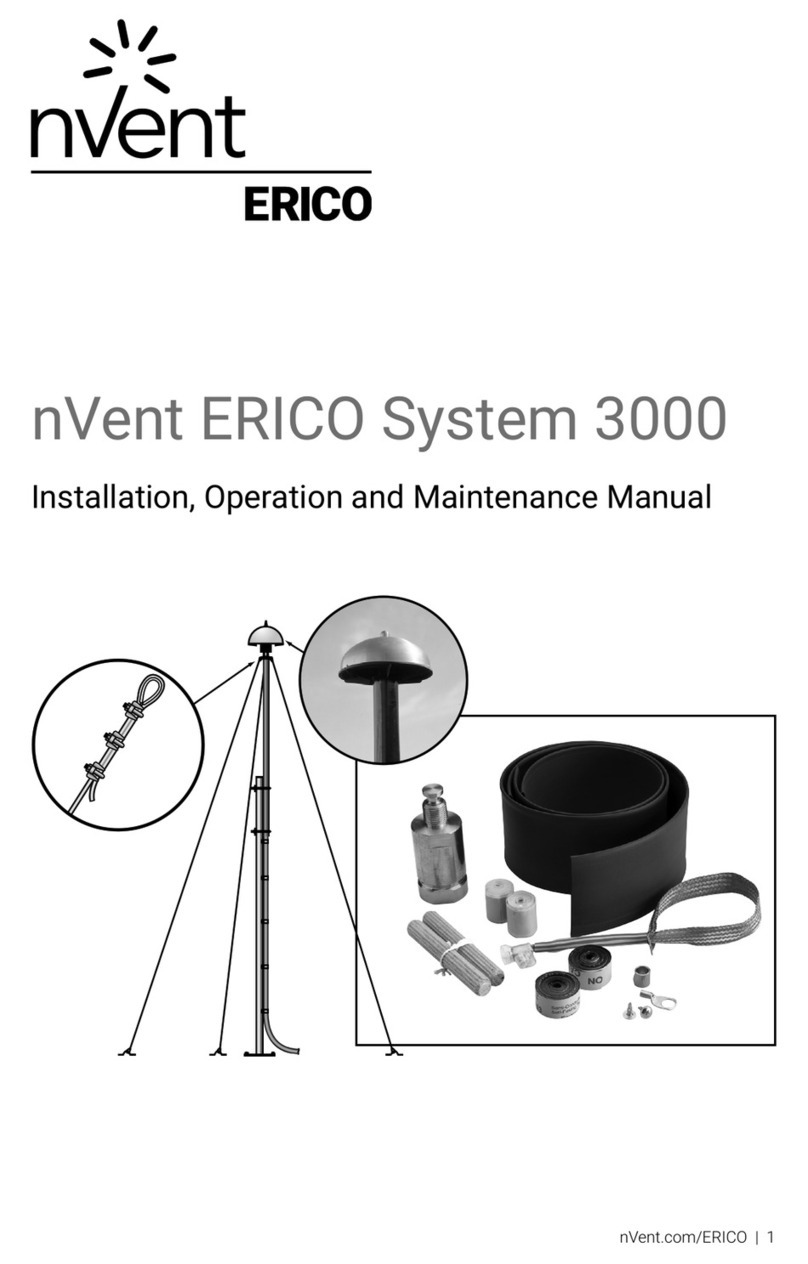

Introduction

Due to ongoing research into the phenomena of lightning and lightning protection technology and product

improvement, nVent ERICO reserves the right to alter any information and specifications contained herein at any

time without notice. Users should check with nVent ERICO to ensure they have the latest edition of this manual.

During thunderstorm conditions, when the lightning down leader is approaching ground level, an upward leader

may be created by any surface. In the case of a passive lightning rod, the upward leader propagates only after

a long period of charge reorganization. In the case of the ESE i-Series, the initiation time of an upward leader

is significantly reduced. The ESE i-Series generates controlled magnitude and frequency pulses at the tip of

the ESE terminal during high static fields prior to a lightning discharge. This enables creation of an upward

leader from the ESE air terminal that propagates toward the thundercloud downward leader.

PURCHASER ACKNOWLEDGES THAT LIGHTENING IS A NATURAL EVENT WITH STATISTICAL

VARIATION IN BEHAVIOR AND 100% PROTECTION IS NOT OFFERED AND CANNOT BE PROVIDED.

The design methods for the placement of nVent ERICO System 1000 ESE air terminals on structures are based

on the calculations using formulas published in the Standard NF C 17-102. The French standard NF C 17-102

is the guiding document for ESE lightning protection systems. The NF C 17-102 standard and this manual shall

be used as the main references for the System 1000 installation. Please note that the French Standard NF C

17-102 is used in other countries under different names of the local standard. Some examples include: Argentina

IRAM 2426, Spain UNE 21186, Macedonia MKS N.B4 810,Portugal NP 4426, Romania I-20, Slovakia STN 34

1391.

IN ALL CASES THE INSTALLER AND THE AUTHORITY HAVING JURISDICTION OVER THE SITE ARE

RESPONSIBLE FOR THE INSTALLATION OF THE ERICO SYSTEM 1000 ESE AS WELL AS ENSURING

THAT THE INSTALLATION COMPLIES TO THE LATEST NF C 17-102 AND IEC EN 62651-2 STANDARDS.

IMPROPER INSTALLATION, MISUSE, MISAPPLICATION OR OTHER FAILURE TO COMPLETELY FOLLOW

ERICO’S INSTRUCTIONS AND WARNINGS MAY CAUSE PRODUCT MALFUNCTION, PROPERTY DAMAGE,

SERIOUS BODILY INJURY AND DEATH. NVENT EXCLUDES ALL OTHER LIABILITY EXCEPT SUCH

LIABILITY THAT IS DIRECTLY ATTRIBUTABLE TO THE GROSS NEGLIGENCE OF NVENTS EMPLOYEES.

SHOULD NVENT BE FOUND LIABLE BY A COURT OF COMPETENT JURISDICTION ITS LIABILITY SHALL

IN NO EVENT EXCEED THE TOTAL PURCHASE PRICE PAID UNDER THE CONTRACT. NVENT SHALL IN

NO EVENT BE RESPONSIBLE FOR ANY LOSS OF BUSINESS OR PROFITS, DOWNTIME OR DELAY,

LABOR, REPAIR OR MATERIAL COSTS OR ANY SIMILAR OR DISSIMILAR CONSEQUENTIAL LOSS OR

DAMAGE INCURRED BY PURCHASER. ALL OTHER TERMS AND CONDITIONS FOR THIS PRODUCT ARE

AS SET OUT IN NVENT ERICOS QUOTATION DOCUMENTS AND TERMS AND CONDITIONS OF SALE.

Operation

The ESE air terminal contains a passive charging circuit that operates automatically. The air terminal becomes

active only during thunderstorms. It does not require external power or component replacement during normal

operation.

Warning: Do not attempt to install the nVent ERICO System 1000 during periods of lightning activity.

This Installation, Operation and Maintenance Manual assumes that in all cases, the System 1000 is designed

by nVent ERICO Engineering or other qualified representative with specific experience in Standard NF C 17-

102. It is understood that a design is formulated using data provided by the customer as to site layout and

measurements and in accordance with all relevant standards.

NVENT DISCLAIMS LIABILITY FOR LOSS OR DAMAGE THAT MAY ARISE DUE TO THE INSTALLATION

OF PRODUCTS WHERE ACTUAL SITE CONDITIONS VARY FROM THOSE PROVIDED TO NVENTIT IS

THE RESPONSIBILITY OF THE CUSTOMER TO ENSURE THAT THE INSTALLATION OF THE PRODUCTS

DOES NOT DEVIATE FROM THE DESIGN PROVIDED BY NVENT OR OTHER QUALIFIED