04/26/02 1 Revision 1.11

TABLE OF CONTENTS

INTRODUCTION............................................................................... 2

General .............................................................................................................2

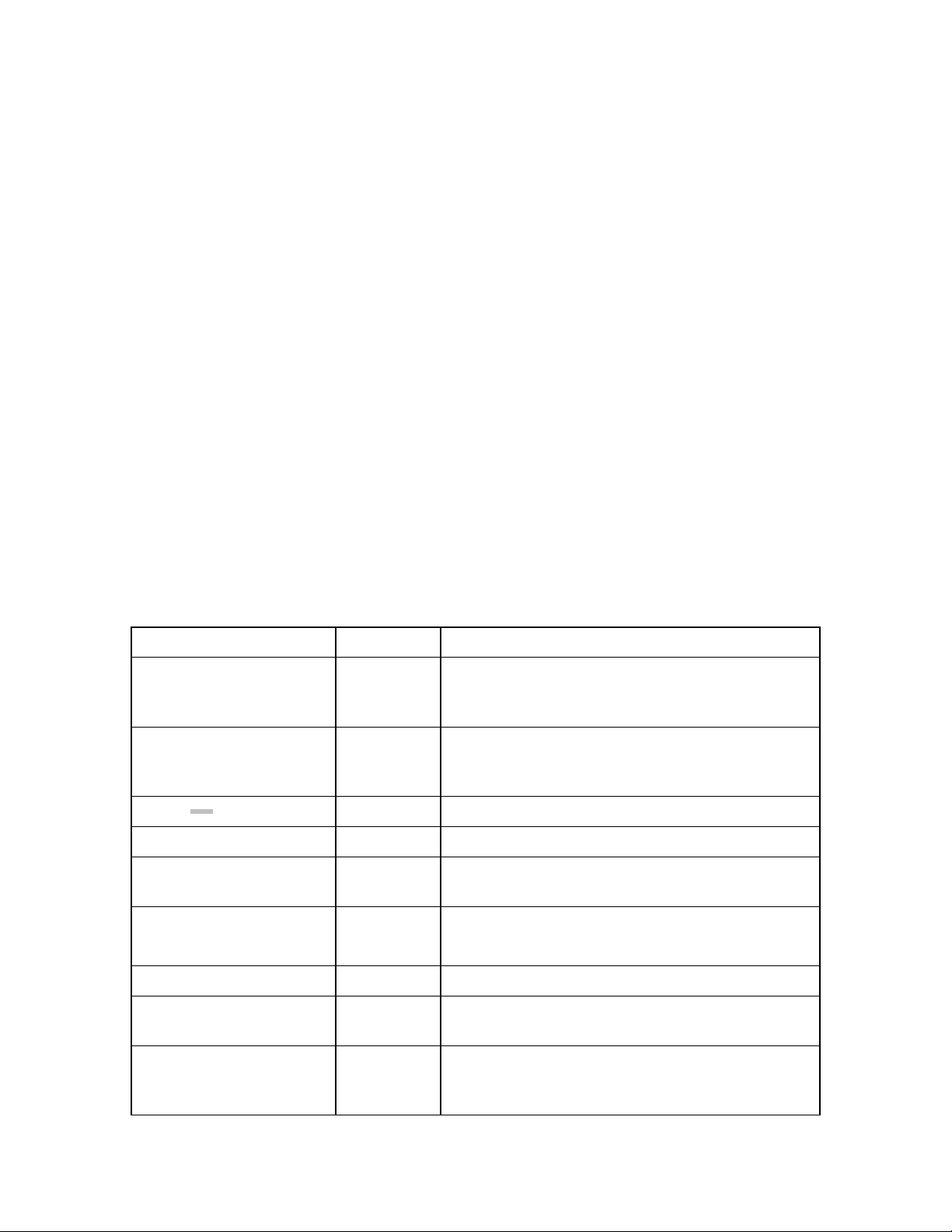

Specifications ....................................................................................................4

INSTALLATION................................................................................ 5

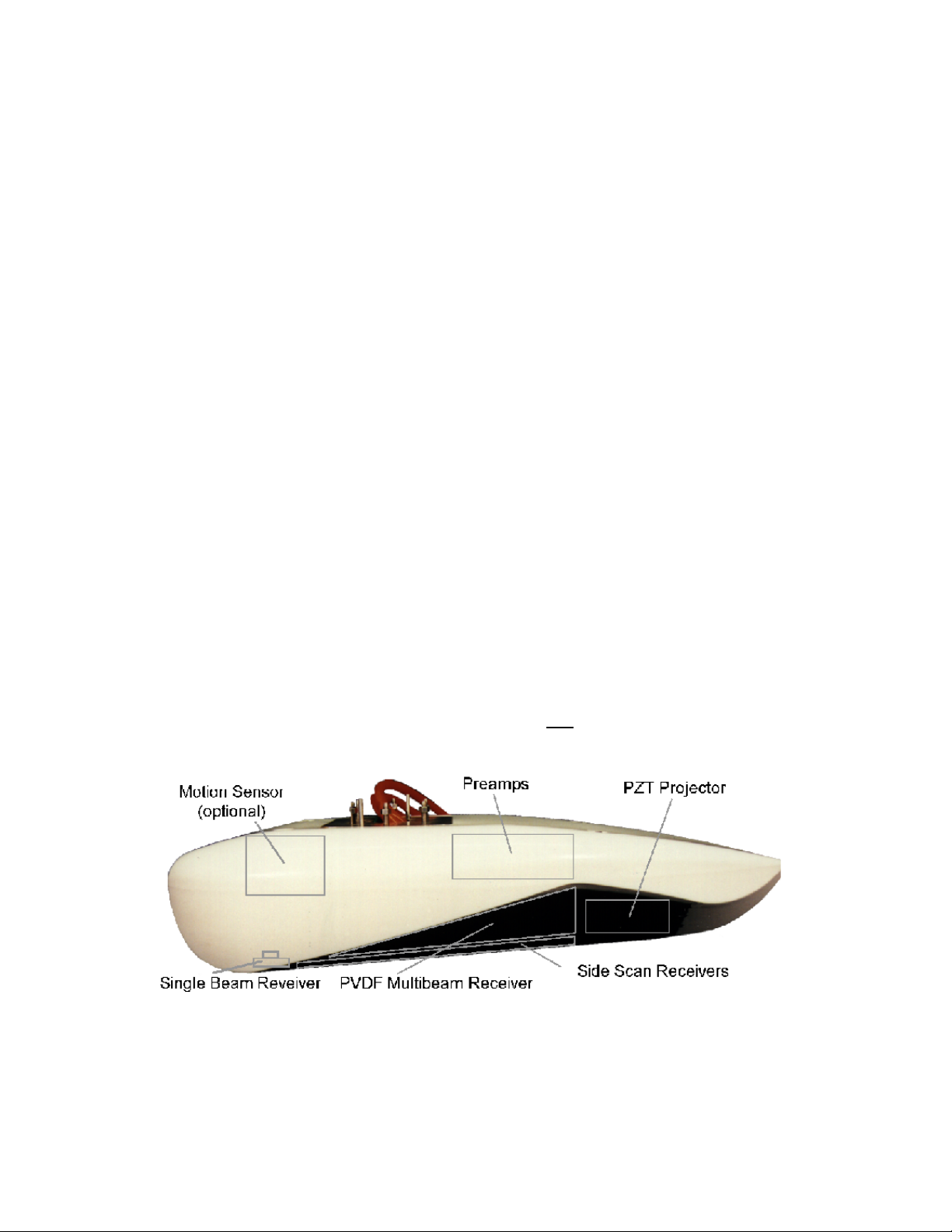

System Components .........................................................................................5

Power Supply Considerations ...........................................................................6

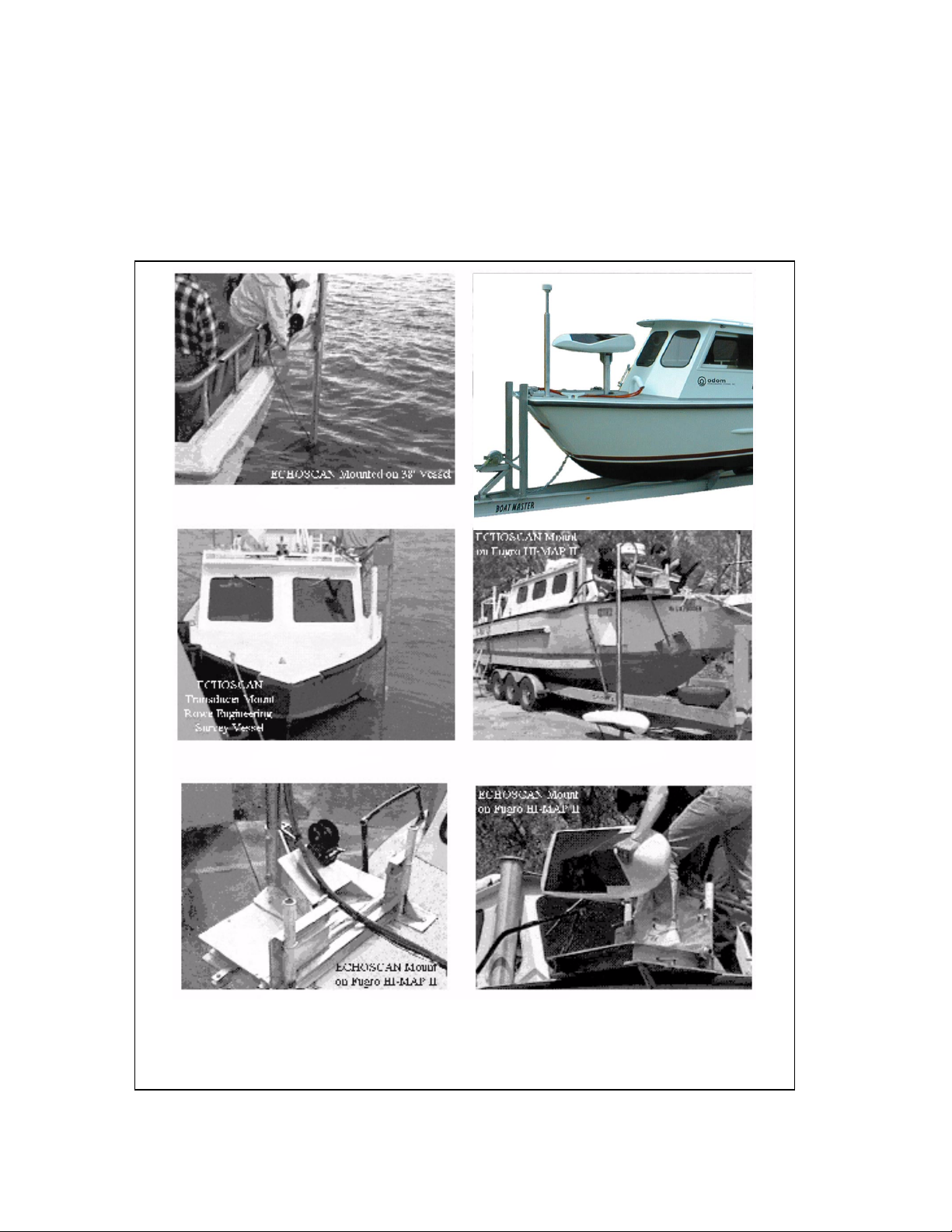

Transducer Installation ......................................................................................7

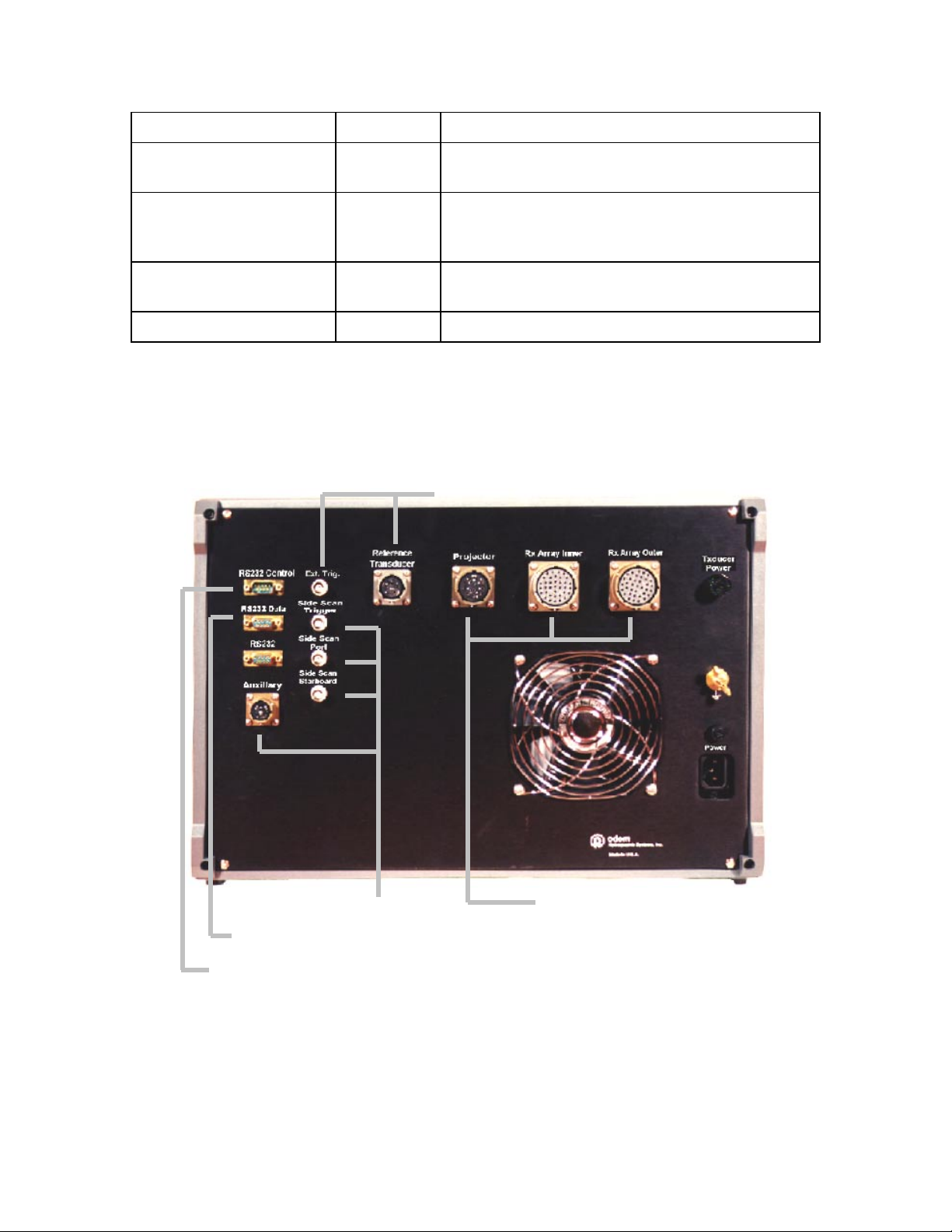

SPU Connections..............................................................................................9

CONTROLS AND INDICATORS .................................................... 11

SPU.................................................................................................................11

LCDU ..............................................................................................................11

Startup Screen ................................................................................................12

File ..................................................................................................................13

Display ............................................................................................................13

Setup...............................................................................................................14

Gain.................................................................................................................15

Digitizer Settings .............................................................................................16

Help.................................................................................................................16

Control Panel...................................................................................................17

OPERATION................................................................................... 20

Power-Up Procedure.......................................................................................20

Example Survey System Configuration ...........................................................21

HYPACK......................................................................................................21

ECHOSCAN Setup ......................................................................................21

HYSWEEP...................................................................................................25

Non-Standard System Configurations.............................................................26

COMMUNICATION CPU - Dip Switch Settings ............................ 29

MULTIBEAM CALIBRATION ......................................................... 31

Bar Check .......................................................................................................31

Referencing to a Single Beam Echo Sounder .................................................31

Combined Velocimeter and Single Beam Calibration......................................31

Flux Gate Compass Alignment........................................................................33

COMPUTER INTERFACE .............................................................. 34

Serial Output Strings .......................................................................................34

ECHOSCAN Output Simulators ......................................................................35

Side Scan Recorder / Processor Interfacing ...................................................36

EXTENDER CABLE WIRING ......................................................... 38

TRANSDUCER CABLES................................................................ 39

JUNCTION BOX WIRING............................................................... 42

HEADING SENSOR WIRING ......................................................... 44