6

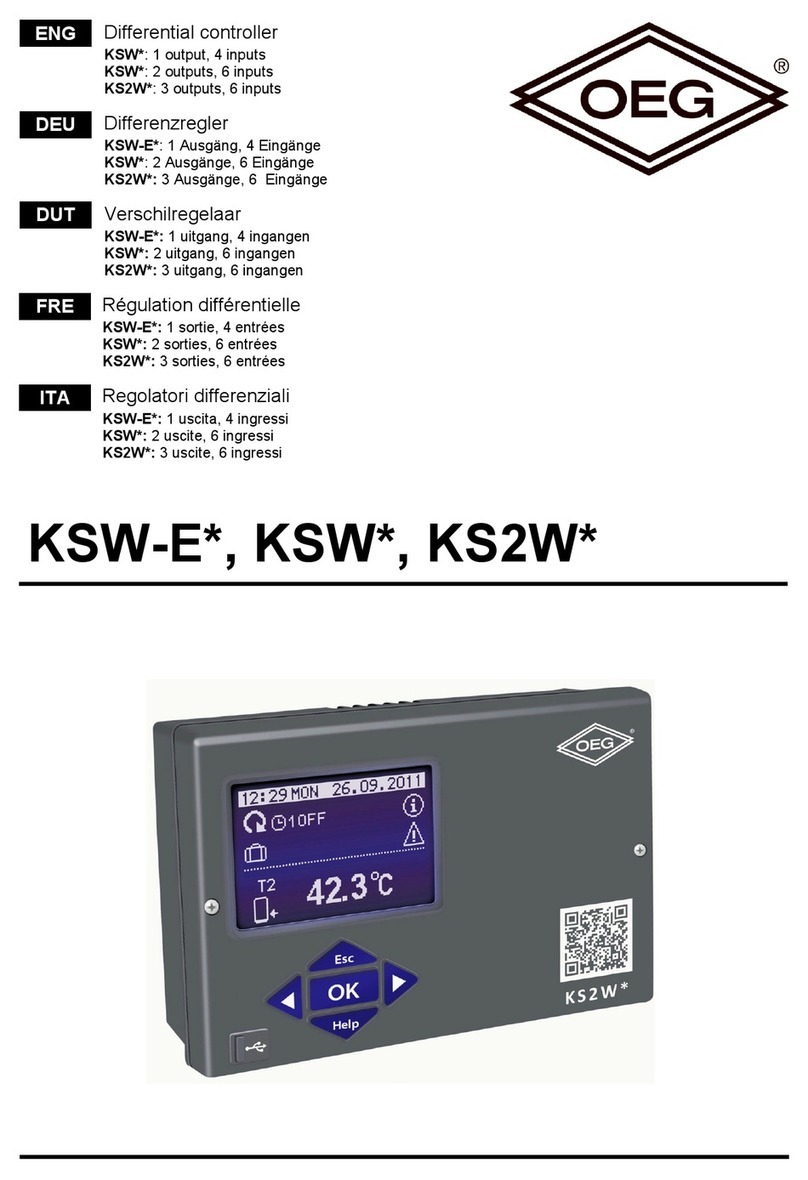

ENG

CONTENTS

Introduction.....................................................................................................................5

USER MANUAL

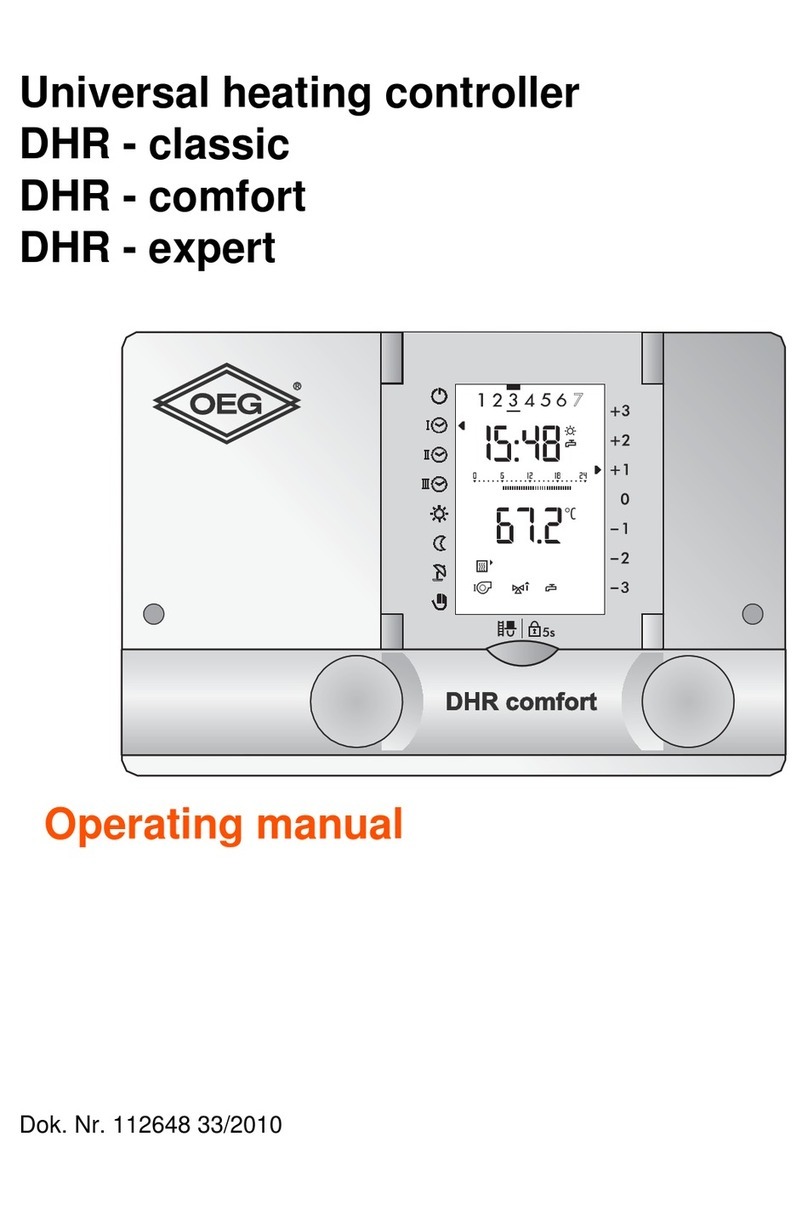

Controller description......................................................................................................8

Initial controller setup......................................................................................................9

Graphic LCD display.......................................................................................................12

Description and presentation of the basic screen: ................................................ 12

Description of symbols presented on the display...........................................................13

Symbols for heating circuits ..................................................................................13

Symbols for operation mode indication.................................................................13

Symbols for user functions....................................................................................13

Symbols for indication of temperatures and other data.........................................14

Symbols for protection functions...........................................................................16

Symbols for the indication of communication between devices............................ 16

Symbols for messages and warnings....................................................................17

Help, messages and warnings screen............................................................................17

Entering and navigating through the menu.....................................................................18

Menu structure and description......................................................................................18

Temperature settings............................................................................................. 23

User functions ....................................................................................................... 24

Operation mode selection .....................................................................................26

Time program settings...........................................................................................28

Basic settings ........................................................................................................ 30

Data overview........................................................................................................ 32

SERVICE SETTINGS MANUAL

Controller parameters.....................................................................................................33

User parameters....................................................................................................33

Heating curve ........................................................................................................ 37

Service parameters...............................................................................................39

Parameters for oor drying....................................................................................50

default settings......................................................................................................51

Mixing heating circuit.............................................................................................52

Basic operation descriptions...........................................................................................52

Direct heating circuit..............................................................................................53

Liquid fuel boiler....................................................................................................53

Solid fuel boiler......................................................................................................54

Heat accumulator..................................................................................................54

Heat pump............................................................................................................. 55

Pump for return-pipe temperature increase (bypass pump)..................................55

Domestic hot water................................................................................................55