i

TABLE OF CONTENTS

CHAPTER 1 INTRODUCTION

1.1 Introdu tion .............................................................................................................1-1

1.2 Servi e Fa ilities .....................................................................................................1-1

1.3 Tools and Test Equipment Required.......................................................................1-2

1.3.1 Spe ial Tools and Test Equipment List ............................................................. 1-2

1.3.2 Standard Tools and Test Equipment List ...........................................................1-2

1.4 Test Masses Required ............................................................................................ 1-2

1.5 Spe ifi ations ..........................................................................................................1-3

CHAPTER 2 DIAGNOSIS

2.1 Troubleshooting ......................................................................................................2-1

2.2 Diagnosti Guide.....................................................................................................2-1

2.2.1 Diagnosis........................................................................................................... 2-1

2.3 Error Codes .............................................................................................................2-4

CHAPTER 3 REPAIR PROCEDURES

3.1 Repair Pro edures ..................................................................................................3-1

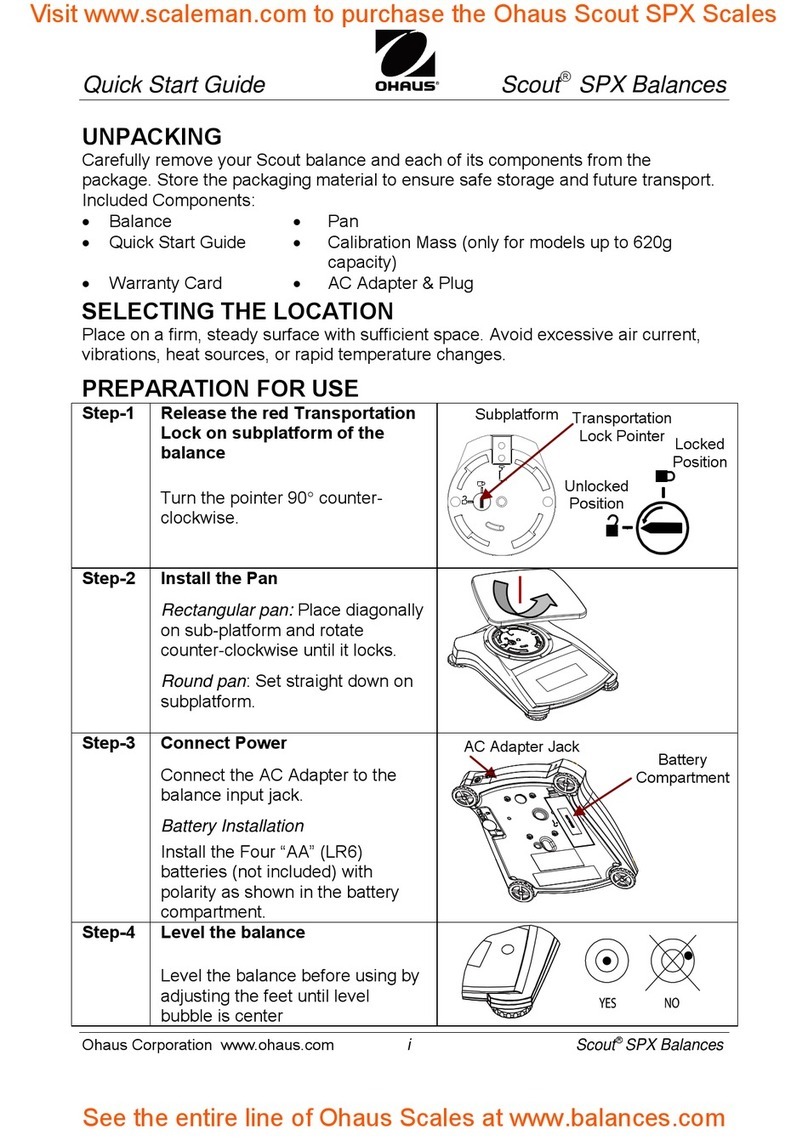

3.1.1 Cover Removal .................................................................................................. 3-1

3.1.2 Printed Cir uit Board Repla ement ...................................................................3-2

3.1.3 Transdu er Repla ement ..................................................................................3-4

CHAPTER 4 TESTING

4.1 Testing ....................................................................................................................4-1

4.1.1 Operation Test ...................................................................................................4-1

4.1.2 Segment Display Test........................................................................................ 4-1

4.2 Performan e Tests ..................................................................................................4-1

4.2.1 Repeatability Test ..............................................................................................4-2

4.2.2 Off-Center Load Test ..........................................................................................4-3

4.2.3 Linearity Test .....................................................................................................4-3

4.3 Down Stop Adjustment ............................................................................................4-4

CHAPTER 5 DRAWINGS AND PARTS LISTS

5.1 Drawings .................................................................................................................5-1

5.2 Parts Lists................................................................................................................ 5-3

APPENDIX A SERVICE TOOL INSTRUCTIONS

A. Servi e Tools Instru tions ...................................................................................... A-1

A.1 Requirements for S out Pro Tools ......................................................................... A-1

A.2 Software Installation ............................................................................................... A-1

A.3 Hardware Installation ............................................................................................. A-1

A.4 Spe ial Instru tions for USB Interfa e .................................................................... A-2

A.5 Using Configtool.Exe ............................................................................................. A-3

A.6 Final Servi e Calibration........................................................................................ A-5

Page No.