CONTENTS

1. CONFIGURATION..................................................................................... 1 - 1

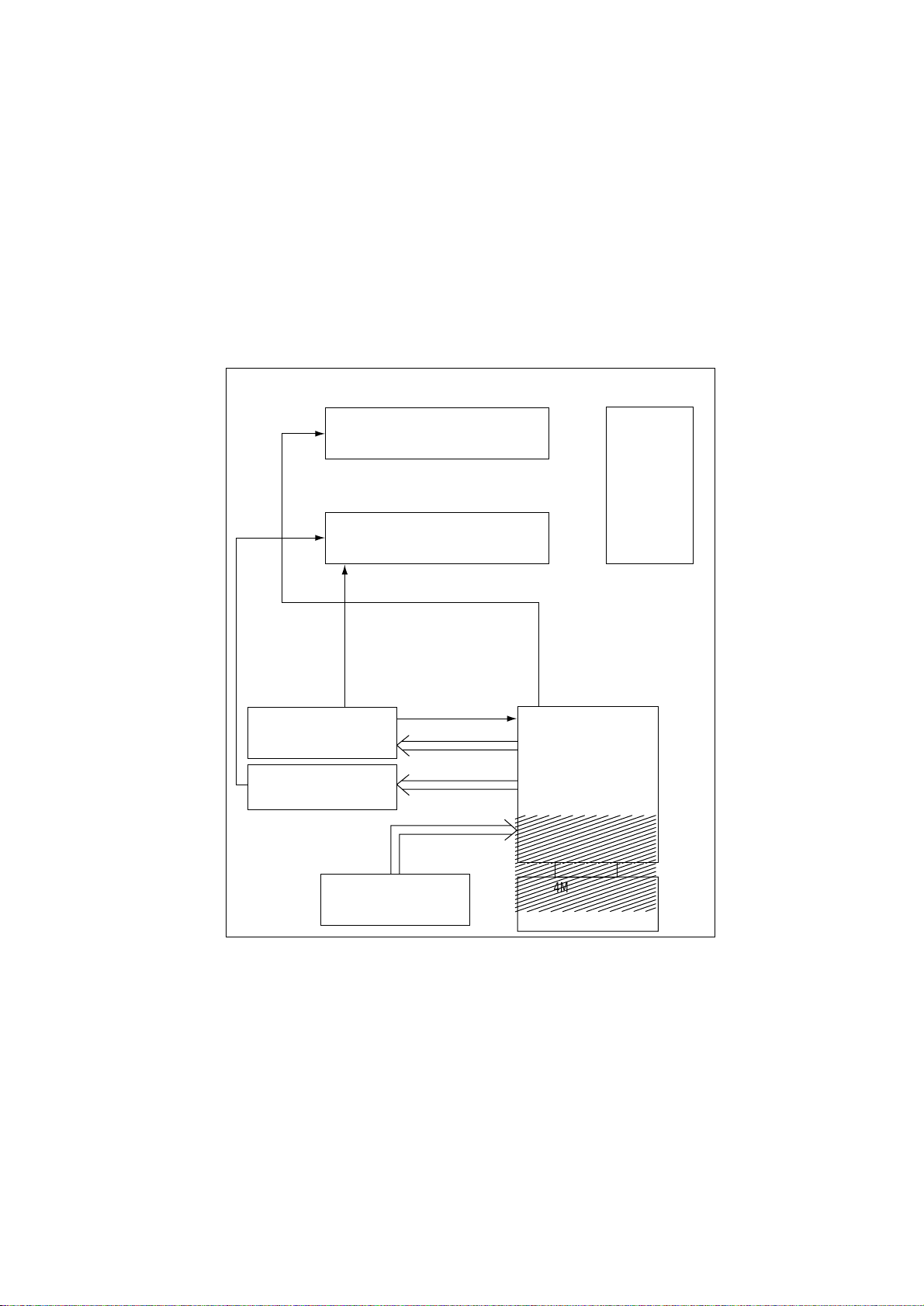

1.1 System Configuration ........................................................................ 1 - 1

1.2 Printer Configuration.......................................................................... 1 - 2

1.3 Option(OKIPAGE 8p Only) ................................................................ 1 - 3

1.4 Specification ...................................................................................... 1 - 4

1.5 Safety Standards ............................................................................... 1 - 6

1.5.1 Certification Label.................................................................................... 1 - 6

1.5.2 Warning Label .........................................................................................1 - 6

2. OPERATION DESCRIPTION .................................................................... 2 - 1

2.1 Main Control Board............................................................................ 2 - 3

2.2 Power Supply Unit ............................................................................. 2 - 5

2.3 High-Voltage Power Supply Board .................................................... 2 - 5

2.4 Electro-Photographic Processor........................................................ 2 - 7

2.5 Electro-Photographic Process ........................................................... 2 - 11

2.5.1 Explanation of Each Process Operation.................................................. 2 - 13

2.6 Paper Jam Detection ......................................................................... 2 - 19

2.7 Toner Low Detection.......................................................................... 2 - 21

2.8 Cover Open ....................................................................................... 2 - 22

2.9 Detecting ID existence....................................................................... 2 - 23

3. PARTS REPLACEMENT........................................................................... 3 - 1

3.1 Precautions for Parts Replacement................................................... 3 - 1

3.2 Parts Layout....................................................................................... 3 - 3

3.3 Replacing Parts ................................................................................. 3 - 7

3.3.1 Hopper Plate ........................................................................................... 3 - 7

3.3.2 LED Head and Head Spring.................................................................... 3 - 8

3.3.3 Transfer Roller.........................................................................................3 - 9

3.3.4 Upper Cover Assy ...................................................................................3 - 10

3.3.5 High-Voltage Power Supply Board (P2H/ P6L) ....................................... 3 - 11

3.3.6 Top Cover Assy and Flat Cable Assy...................................................... 3 - 12

3.3.7 Paper Holder ...........................................................................................3 - 13

3.3.8 Side Plate M and Idle Gear .....................................................................3 - 14

3.3.9 Heat Assy ................................................................................................ 3 - 15

3.3.10 Drive Shaft E (Eject) and Eject Roller ..................................................... 3 - 18

3.3.11 Pressure Roller B (Back Up Roller)......................................................... 3 - 19

3.3.12 Separator Guide ...................................................................................... 3 - 20

3.3.13 Pulse Motor (Main) .................................................................................. 3 - 23

3.3.14 Hopping Shaft Assy ................................................................................. 3 - 24

3.3.15 Resist Roller ............................................................................................ 3 - 25

3.3.16 Paper Sensor E, Paper Sensor Exit and Toner Sensor Assy ................. 3 - 26

3.3.17 Base Plate ............................................................................................... 3 - 27