3

Index

1PREFACE .....................................................................................................................................................................................4

2SYMBOL DESCRIPTION ..........................................................................................................................................................5

SYMBOLS USED IN THIS MANUAL...............................................................................................................................................................5

SYMBOLS ON THE PRODUCT LABEL ...........................................................................................................................................................5

3SAFETY NOTES..........................................................................................................................................................................6

4SUPPLIED EQUIPMENT..........................................................................................................................................................8

5GAS SUPPLIED REQUIREMENTS .........................................................................................................................................9

6COMPATIBILITY.......................................................................................................................................................................9

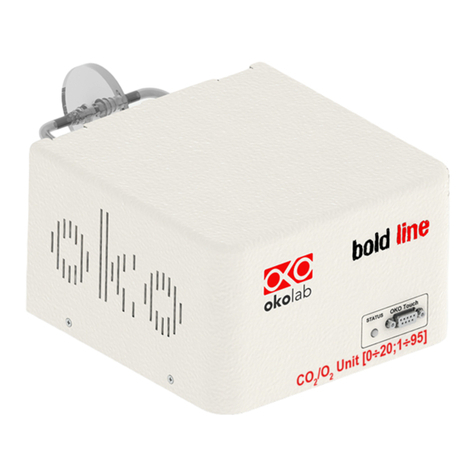

7EQUIPMENT DESCRIPTION ............................................................................................................................................... 11

8INSTALLATION ...................................................................................................................................................................... 12

SETTING UP CO2-O2-UNIT-BL [0-10; 1-18].................................................................................................................................12

HOW TO ASSEMBLE CO2-O2-UNIT-BL [0-10; 1-18] WITH A BOLD LINE TCONTROLLER ....................................................19

9USER INTERFACE .................................................................................................................................................................. 21

HOME PAGE................................................................................................................................................................................................21

9.1.1 How to enter the set point ......................................................................................................................................................22

9.1.1.1 How to operate without N2.......................................................................................................................................................................... 22

CONTROLLER STATUS:COLOURS LED AND MEANING..........................................................................................................................24

SETTINGS....................................................................................................................................................................................................25

9.3.1 Gas......................................................................................................................................................................................................25

9.3.1.1 Air Source............................................................................................................................................................................................................25

9.3.1.2 Calibrations........................................................................................................................................................................................................ 27

9.3.1.2.1 Offset (with exthernal meter).............................................................................................................................................................27

9.3.1.2.2 Sensors (with calibration gas)........................................................................................................................................................... 29

9.3.1.2.2.1 View ......................................................................................................................................................................................................29

9.3.1.2.2.2 Span Settings .................................................................................................................................................................................... 30

9.3.1.2.2.3 Factory Reset ....................................................................................................................................................................................30

9.3.1.2.2.4 Start Span........................................................................................................................................................................................... 31

9.3.1.2.2.5 Start Zero............................................................................................................................................................................................31

9.3.1.2.2.6 Start Air............................................................................................................................................................................................... 32

9.3.1.2.3 Factory Reset.............................................................................................................................................................................................33

9.3.1.3 Flowrates............................................................................................................................................................................................................. 33

9.3.1.4 Gas cycles............................................................................................................................................................................................................. 35

9.3.1.5 Status ....................................................................................................................................................................................................................37

9.3.1.6 Digital Input.......................................................................................................................................................................................................37

9.3.2 Touch Screen configuration ...................................................................................................................................................38

9.3.2.1 Touch Screen Options..................................................................................................................................................................................... 38

9.3.2.2 Touch Screen Brightness ..............................................................................................................................................................................39

9.3.2.3 Touch Screen Visual Effects –icon and glance mode.......................................................................................................................39

9.3.2.4 Date & Time........................................................................................................................................................................................................ 40

9.3.2.5 Alarms...................................................................................................................................................................................................................40

9.3.2.6 Data Logging .....................................................................................................................................................................................................42

OVERVIEW..................................................................................................................................................................................................45

ICON AND GLANCE MODE VIEW.............................................................................................................................................................46

INFO PAGE ..................................................................................................................................................................................................46

10 TOUCH SCREEN CALIBRATION .................................................................................................................................... 48

11 CLEANING & MAINTENANCE......................................................................................................................................... 49

12 SUPPORT ............................................................................................................................................................................. 50

13 TECHNICAL SPECIFICATIONS ....................................................................................................................................... 51

14 TROUBLESHOOTING........................................................................................................................................................ 52

15 FIGURE LIST........................................................................................................................................................................ 53

16 MANUAL REVISION TABLE ............................................................................................................................................ 55