3

DC-ITD-EC20xMAN01_A DODtec.com

REV 12/21/2022 815-788-5200

EC20x Cabinet Operating Manual

Chapter 1 – Overview

1.1 Introduction

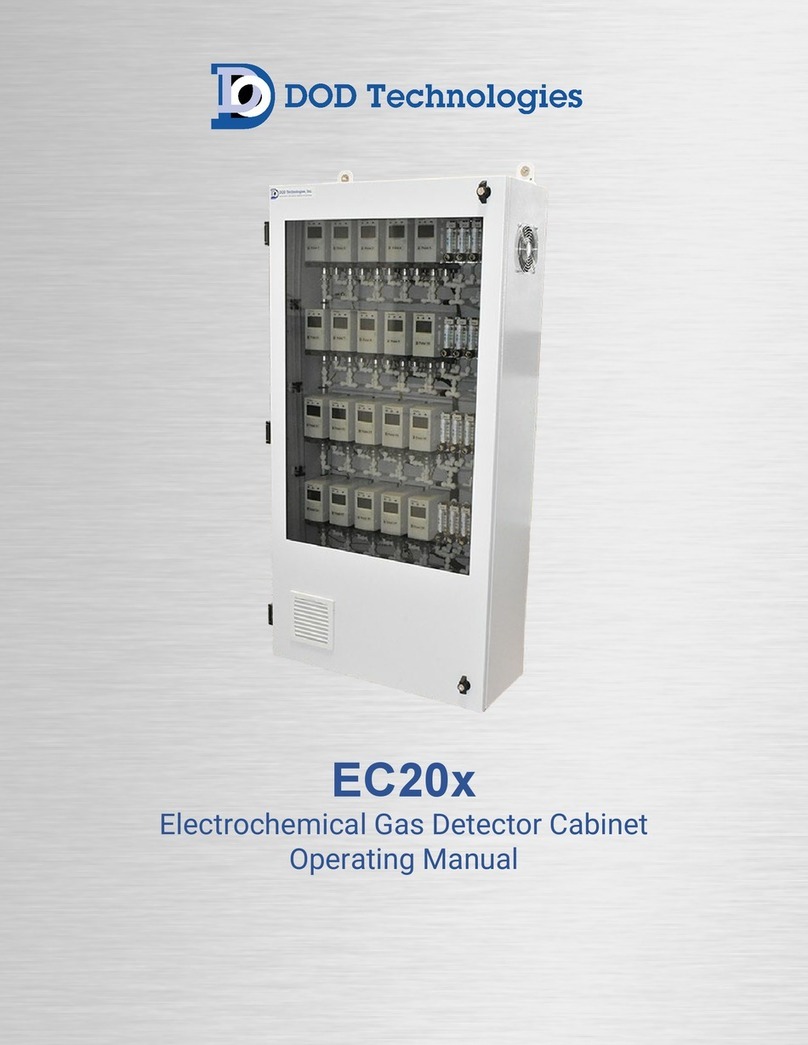

DOD Technologies’ EC20x Gas Detector Cabinet is designed to house a series of single-point electrochemical

gas detectors – see specifications for compatibility. While creating a centralized hub, the EC20x is fully

customizable from the factory. This transforms a seemingly ordinary cabinet into a robust toxic gas

monitoring system (TGMS) with improved transport time and extractive detection from distances up to 600

feet.

1.2 Theory of Operation

The EC20x simply requires AC power (110VAC or 230VAC – pump dependent), sample tubing - 1/4” OD x

3/16” ID FEP Teflon (up to 20 points) and exhaust tubing – 3/8” OD x ¼” ID x 25’ maximum (two required and

provided with your system).

The cabinet comes standard with (4) pumps total (one for points 1-10, one for points 11-20, and one backup

pump for each in case of a pump failure). If the instrument detects a pump failure, the backup pump switches

automatically and notifies the user of the problem via a Form C (NO, NC, COM) output relay (one output relay

for each primary pump). The EC20x also has a redundant power supply in case of failure and (2) Form C

relays to notify the user in the event of a failure.

WARNING : If the system is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.