Oldham OLC 100 User manual

Other Oldham Gas Detector manuals

Oldham

Oldham OLC 100 User manual

Oldham

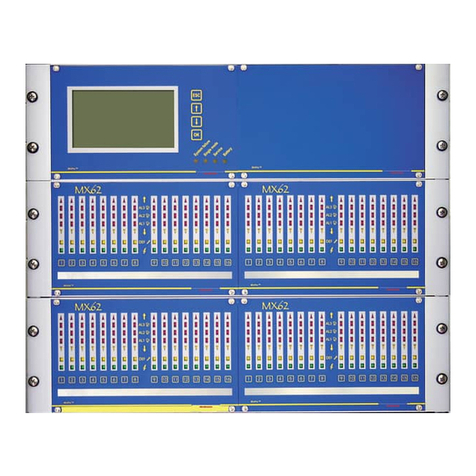

Oldham MX62 User manual

Oldham

Oldham OLC 10 User manual

Oldham

Oldham OLC 10 User manual

Oldham

Oldham CTX 300 CO2 User manual

Oldham

Oldham SV 4B User manual

Oldham

Oldham OLC 100 User manual

Oldham

Oldham Surveyor 4B Installation guide

Oldham

Oldham OLCT 20 User manual

Oldham

Oldham MX62 User manual

Popular Gas Detector manuals by other brands

Macurco

Macurco GD-6 Operation manual

Evikon

Evikon E2632 user manual

Critical Environment Technologies

Critical Environment Technologies CGAS-A Series Installation & operation manual

MSA

MSA altair 5 operating manual

DOD Technologies

DOD Technologies ChemLogic CL96 operating manual

DEGA

DEGA NS III LCD Series instruction manual

RKI Instruments

RKI Instruments 35-3001A-08-01 Operator's manual

Sygonix

Sygonix 2483186 operating instructions

Perry

Perry 1GA 50917MET/P Installation and operating instructions

isweek

isweek AS8900 manual

Wizmart

Wizmart NB983 installation instructions

Beacon

Beacon MEGA Installation, operation and maintenance instructions