2/4

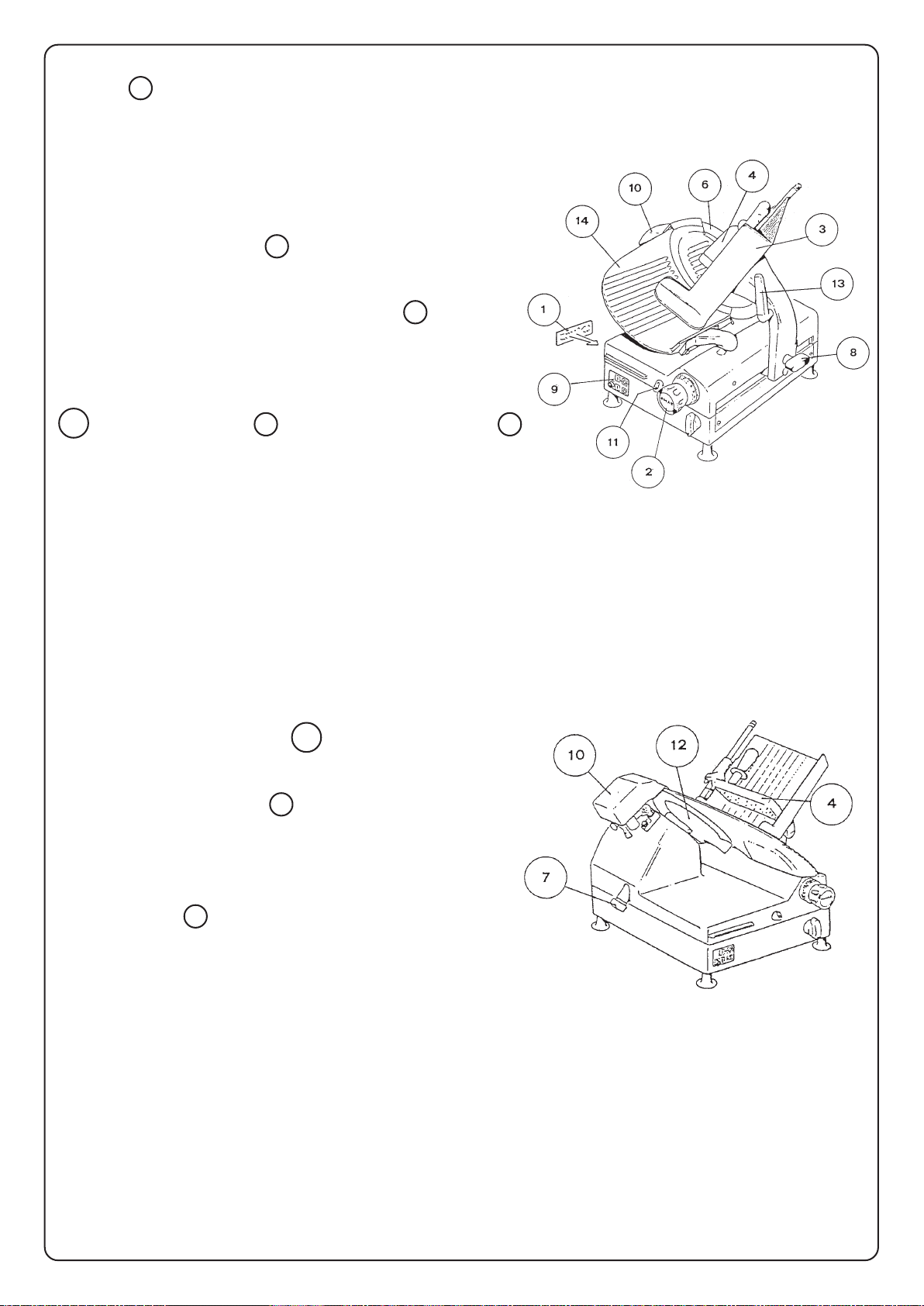

When the siicer is not working, the slicer thickness

control 2 mustbesetonzero(fuIlyclockwise)toprevent

the blade edge from being exposed.

AlwaysUNPLUGthepowercordbeforecleaningormoving

theslicer.

SLICING

PuII the product holder 3 towards you until it stops

andplacetheproduct to be slicedonthe product holder

tray. Place the last slice device against the product and

startthe slicer by pressingtheon-offswtich 9 .Adjustthe

slicethicknessbyturningtheslicethicknesscontrol.The

numbers on the slice thickness control do not indicate

precise measurement, but may be used for reference to

duplicateslicethickness.Usingeitherthecarriagehandle

13 orIast slice device 4 pushtheproduct holder 3

back and forth to slice. Always swtich-off the slicer and

turnthe slice thickness control clockwise tozero when

notslicing.

WARNING: Slicershouldnotbeoperatedbyuntrained

personnelor persons under18yearsofage.

CLEANING

Thismachinemustbethoroughlycleanedaftereachday’s

operationorevery time it willnotbe used foranextended

period.

WARNING: UNPLUGMACHINE POWERCORD

AND TURN THE INDEX KNOB FULLY CLOCKWISE

BEFORECLEANINGTHE SLICER.

Removethe slice deflector 12 byremovingitsthumb

screw.

Theproductholdercanberemovedforaneasy cleaning

byunfastening its handle 8 .

Usingamildsoapandhotwatersolutionandacleancloth,

wipeallsurfaces of theslicer.

Thoroughlyrinseitwithanothercleanclothandfreshwater.

Remove the blade cover byremoving

the hand knob 7 . With the hand knob removed, grasp

theedgeof the blade cover andcarefullyliftitstraight off

theknife.

WARNING:THE SLICER BLADE IS VERYSHARPUSE

EXTREME CAUTION WHEN WORKING NEAR THE

BLADE.

CAREFULLYwash bothsides of theblade withthe slice

thicknesscontrol turnedfullyclockwise. Washtheblade

by wiping outward from the center. ALWAYS rinse the

bladethoruogthlyusingfreshwaterandacleancloth.Never

use steel pads it clean the blade. Wash and thoroughly

rinsetheremovedcamponentspriortoreassemblingthem.

DONOTwash anyslicercomponents in a dishwasher.