L388BS002

8

Art.

DICHIARAZIONE CE DI CONFORMITÀ ai sensi dell’Art. 12, paragrafo 2. della Direttiva 2006/42/CE

EC DECLARATION OF CONFORMITY in accordance with Art. 12, paragraph 2., Directive 2006/42/EC

EG-KONFORMITÄTSERKLÄRUNG gemäß des Art. 12, Paragraph 2. der Richtlinie 2006/42/EG

DÉCLARATION CE DE CONFORMITÉ conformément à la Directive 2006/42/CE, Art. 12, paragraphe 2.

DECLARACIÓN CE DE CONFORMIDAD con arreglo al Art. 12, paràgrafo 2. de la Directiva 2006/42/CE

Noi/We/Wir/Nous/Nosotros:

OMCN S.p.A. via Divisione Tridentina 23, 24020 Villa di Serio (Bergamo), ITALIA

dichiariamo sotto la nostra esclusiva responsabilità che il prodotto

declare, with sole responsibility on our part, that the product

erklären unter unserer alleinigen Verantwortung, daß das Produkt

déclarons, sous notre entière responsabilité, que le produit

declaramos bajo nuestra exclusiva responsabilidad que el producto

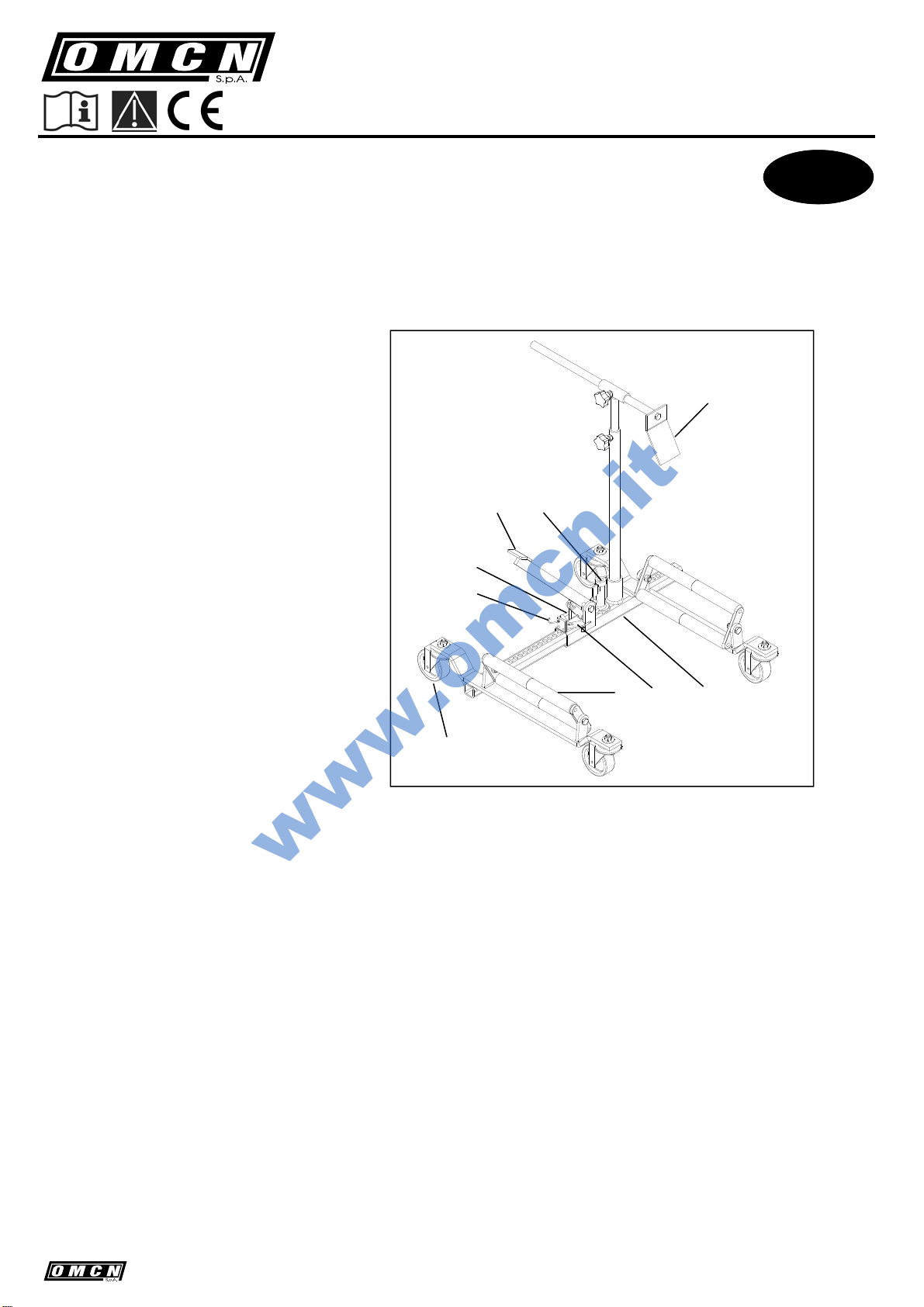

Apparecchio di sollevamento meccanico

Mechanical lifting equipment

Mechanische hubgeräte

Équipement mécanique de levage

Equipo mecanico de elevación

N. Lotto

Lot code

Partienummer

Lot N

Numero de lote

al quale questa dichiarazione si riferisce è conforme alle seguenti disposizioni legislative:

to which this declaration refers conforms to the following legislative dispositions:

auf die sich diese Erklärung bezieht entspricht den folgenden rechtlichen Vorschriften:

auquel cette déclaration se réfère est conforme aux dispositions législatives:

al que se refiere esta declaración es conforme a las siguientes disposiciones legislativas:

Direttiva 2006/42/CE (Sicurezza macchine)

Directive 2006/42/EC (Safety of machine)

Richtlinie 2006/42/EG (Maschinensicherheit)

Directive 2006/42/CE (Sécurité des machines)

Directiva 2006/42/CE (Seguridad de la maquina)

Sono state utilizzate le seguenti norme e specificazioni tecniche:

The following standards and technical specifications have been used:

Es wurden folgende Normen und technische Spezifikationen verwendet:

On a utilisé les normes et les spécifications techniques suivantes:

Se han utilizado las siguientes normas y especificaciones técnicas:

L’apparecchiatura è stata fabbricata in conformità a quanto previsto dall’Allegato VIII, paragrafo 3., della Direttiva 2006/42/CE

The equipment was built according Annex VIII, paragraph 3., Directive 2006/42/EC

Die Werkstattausrüstung war gemäß der Anlage VIII, Paragraph 3 der Richtlinie 2006/42/EG hergestellt

L’équipement a été fabriqué suivant ce qui est prévu par l’Annexe VIII, paragraphe 3., Directive 2006/42/CE

El aparatos se ha costruido según lo previsto por lo anexo VIII, paràgrafo 3. de la Directiva 2006/42/CE

Nome ed indirizzo della persona autorizzata alla costituzione del fascicolo tecnico:

Name and address of the person authorised to compile the technical file:

Name und Anschrift der Person, die bevollmächtigt ist, die technischen Unterlagen zusammenzustellen:

Nom et dresse de la personne autorisée à constituer le dossier technique:

Nombre y dirección de la persona facultada para elaborar el expediente técnico:

PAOLO CORTINOVIS, via Divisione Tridentina 23, 24020 Villa di Serio (Bergamo), ITALIA

Luogo e data:

Place and date:

Ort und Datum:

Lieu et date:

Lugar y fecha:

EN 349:1993+A1:2008 EN ISO 13857:2008

EN ISO 12100:2010

EN ISO 13849-1:2008/AC:2009

Villa di Serio (BG),

Paolo Cortinovis

AMMINISTRATORE

MANAGER

ADMINISTRATOR

ADMINISTRATEUR

GERENTE

ASM2-AC-0012