©OMRON Corporation 2004-2010 All Rights Reserved.

OMRON's exclusive warranty is that the products are free from

defects in materials and workmanship for a period of one year (or

other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION,

EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR

PURPOSE OF THE PRODUCTS. ANY BUYER OR USER

ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET

THE REQUIREMENTS OF THEIR INTENDED USE. OMRON

DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED.

●WARRANTY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL,

INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF

PROFITS OR COMMERCIAL LOSS IN ANY WAY

CONNECTED WITH THE PRODUCTS, WHETHER SUCH

CLAIM IS BASED ON CONTRACT, WARRANTY,

NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed

the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR

WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT

THE PRODUCTS WERE PROPERLY HANDLED, STORED,

INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE

MODIFICATION OR REPAIR.

●LIMITATIONS OF LIABILITY

OMRON shall not be responsible for conformity with any standards,

codes, or regulations that apply to the combination of the product in

the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third

party certification documents identifying ratings and limitations of

use that apply to the products. This information by itself is not

sufficient for a complete determination of the suitability of the

products in combination with the end product, machine, system, or

other application or use.

The following are some examples of applications for which

particular attention must be given. This is not intended to be an

exhaustive list of all possible uses of the products, nor is it intended

to imply that the uses listed may be suitable for the products:

Outdoor use, uses involving potential chemical contamination or

electrical interference, or conditions or uses not described in this

instruction sheet.

Nuclear energy control systems, combustion systems, railroad

systems, aviation systems, medical equipment, amusement machines,

vehicles, safety equipment, and installations subject to separate

industry or government regulations.

Systems, machines, and equipment that could present a risk to life or

property.

Please know and observe all prohibitions of use applicable to the

products.

NEVER USE THE PRODUCT FOR AN APPLICATION

INVOLVING SERIOUS RISK TO LIFE OR PROPERTY

WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT

THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

●SUITABILITY FOR USE

Performance data given in this manual is provided as a guide for the

user in determining suitability and does not constitute a warranty. It

may represent the result of OMRONs test conditions, and the users

must correlate it to actual application requirements. Actual

performance is subject to the OMRON Warranty and Limitations of

Liability.

●PERFORMANCE DATA

Product specifications and accessories may be changed at any time

based on improvements and other reasons. Consult with your

OMRON representative at any time to confirm actual specifications

of purchased product.

●CHANGE IN SPECIFICATIONS

Dimensions and weights are nominal and are not to be used for

manufacturing purposes, even when tolerances are shown.

●DIMENSIONS AND WEIGHTS

The information in this document has been carefully checked and is

believed to be accurate; however, no responsibility is assumed for

clerical, typographical, or proofreading errors, or omissions.

●ERRORS AND OMISSIONS

This document shall not be copied for sales or promotions without

permission.

This document is protected by copyright and is intended solely for

use in conjunction with the product. Please notify us before copying

or reproducing this document in any manner, for any other purpose.

If copying or transmitting this document to another, please copy or

transmit it in its entirety.

●COPYRIGHT AND COPY PERMISSION

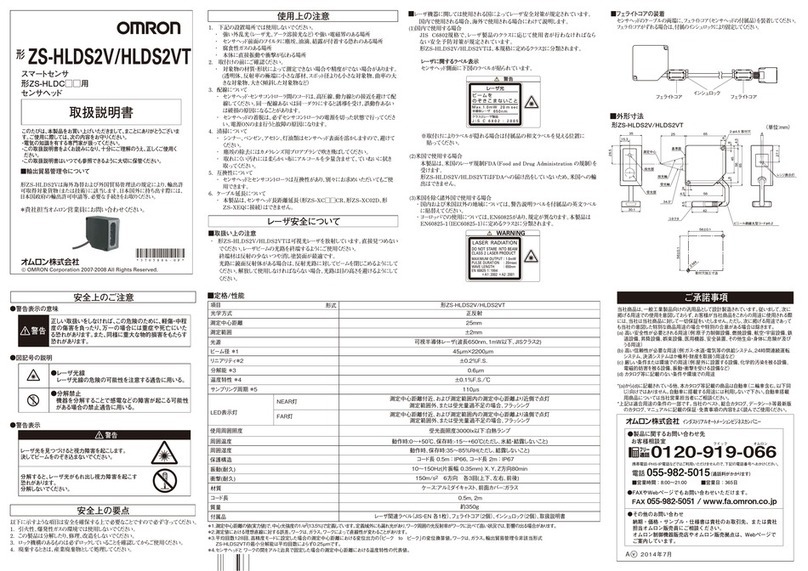

SINGLE BEAM SAFETY SENSOR

ModelE3ZS-T81A

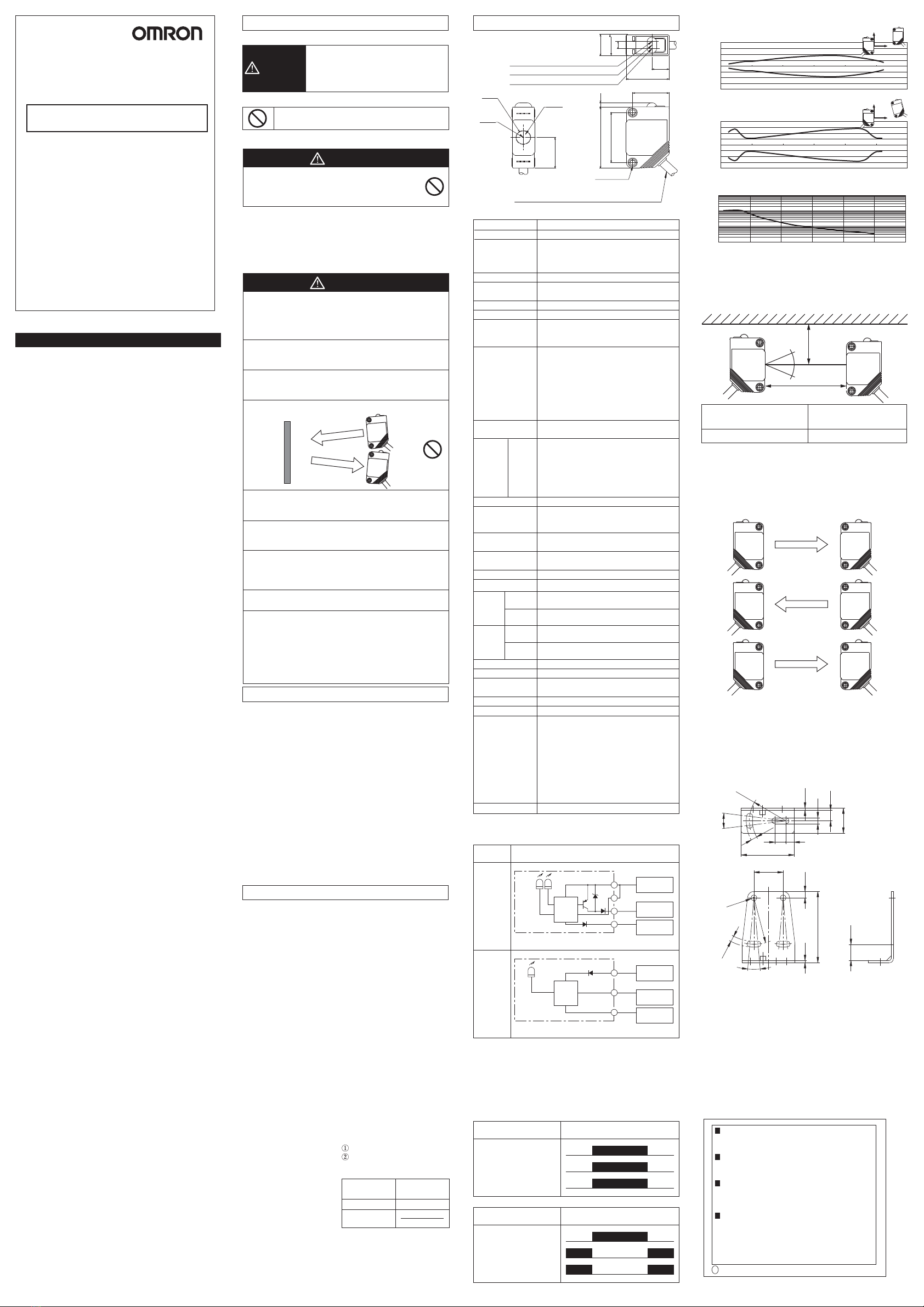

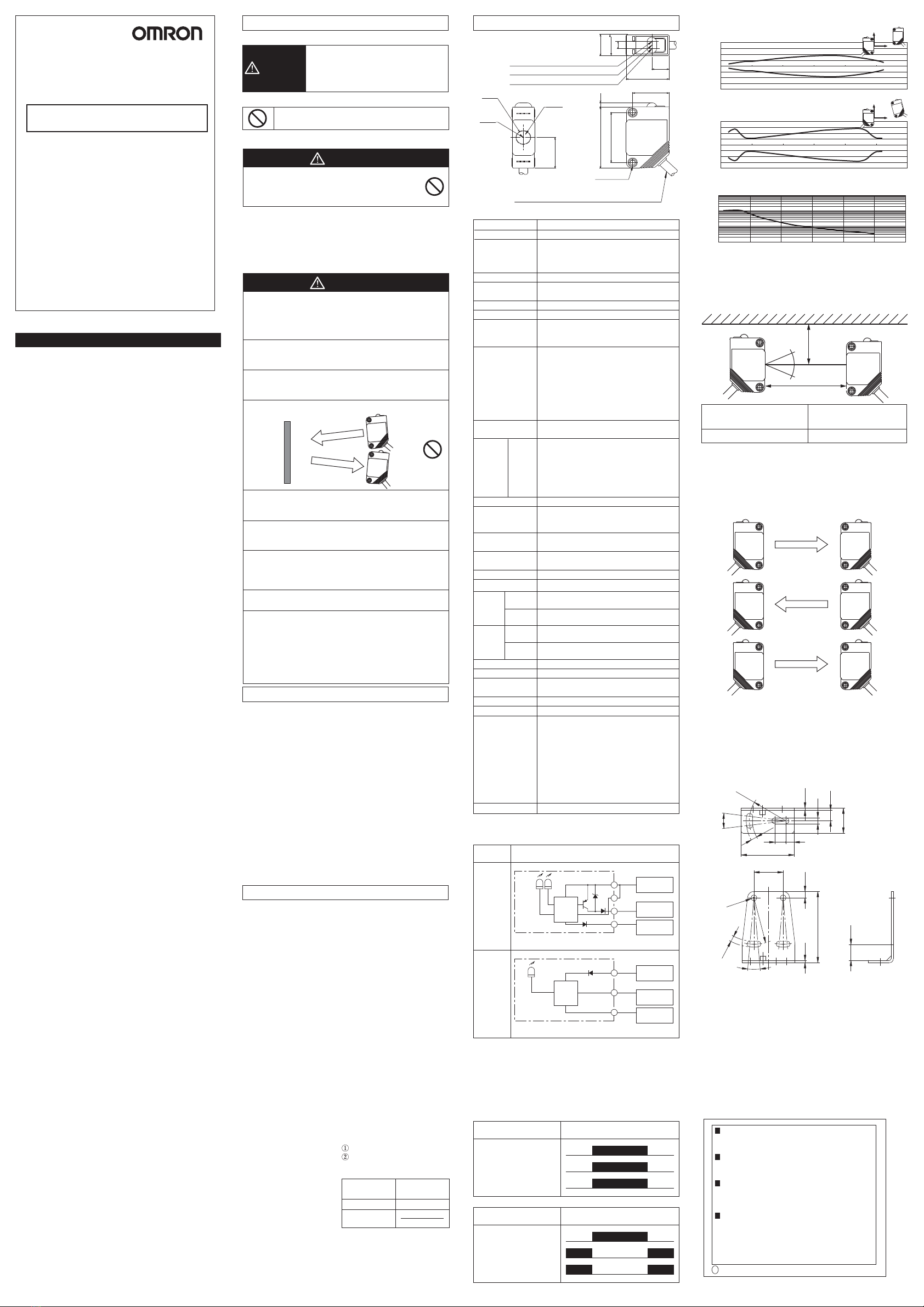

■TIMING CHART

●Output mode and timing chart

On when incident (Light ON)

Timing chart

Light incident

Light interrupted

Indicator Green

Red

Control ON

output OFF

●Emitting timing chart

Timing chart

・The F3SX executes a periodic self-diagnosis every 20 ms.

Test input ON

OFF

Light emission ON

OFF

Indicator ON

(Orange) OFF

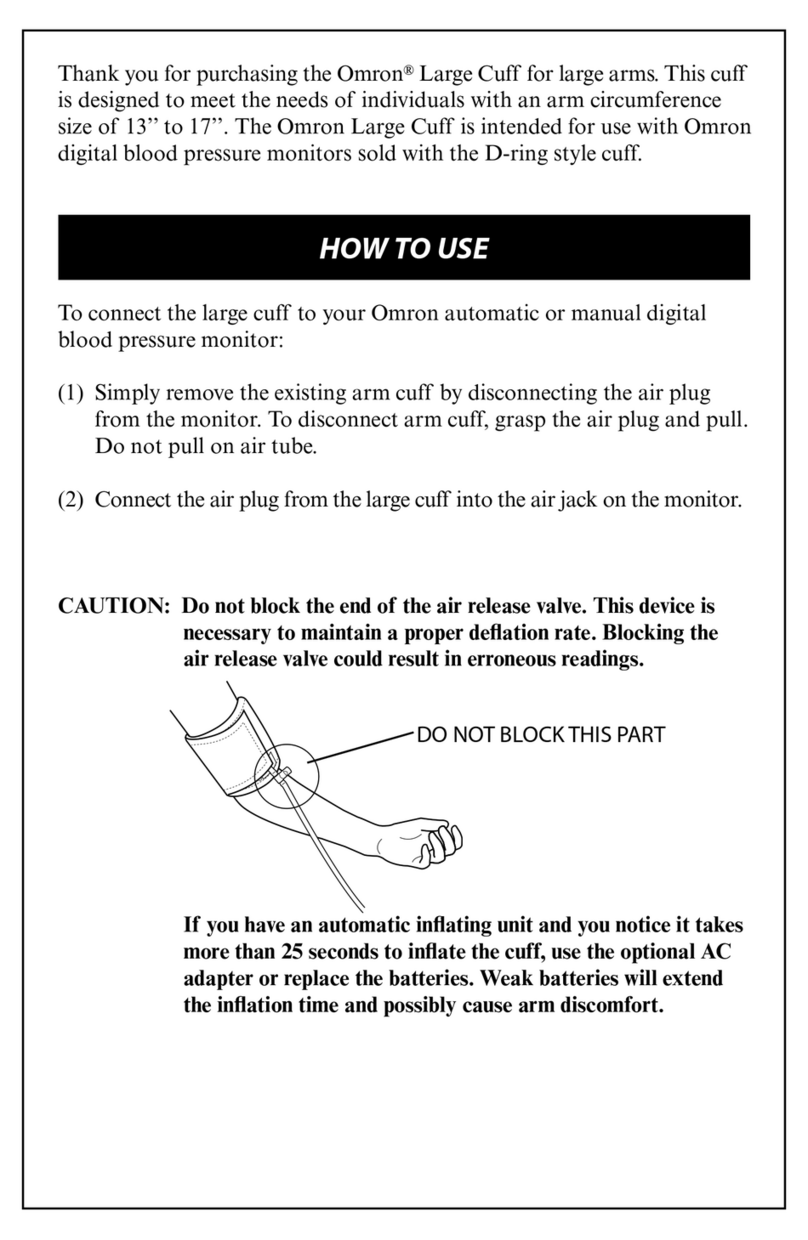

●Mounting Bracket (Model E39-L104)

■ACCESSORY (OPTIONAL)

■

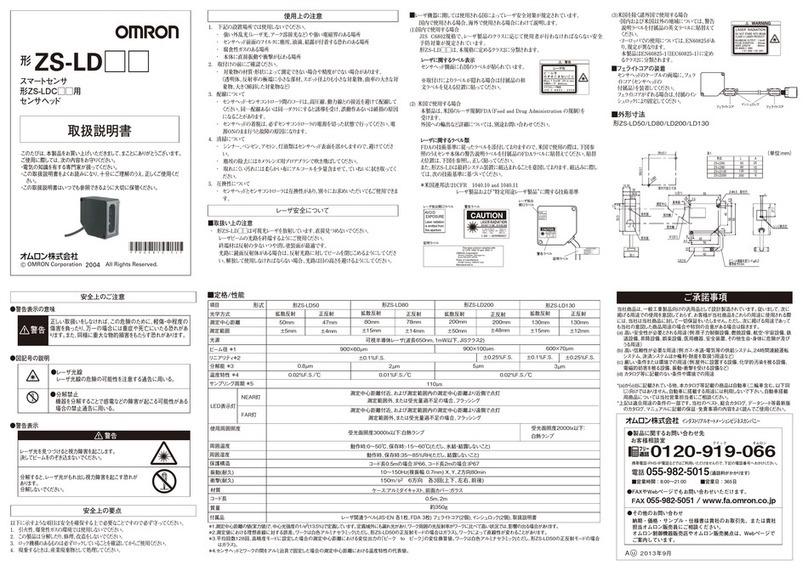

INFLUENCE OF MUTUAL INTERFERENCE

When installing two or more E3ZSs to each other, considerations must

be made to prevent mutual interference.

・Install so that any E3ZSs emit in the opposite directions (See below).

・

Install a light interrupting wall in between sensors.

・Install the E3ZSs facing away from the one another to

eliminate mutual interference.

Note : When using multiple sets of E3ZSs, be sure to

confirm that mutual interference is not occurred.

Emitter

Receiver

Emitter

Receiver

Emitter

Receiver

10゚

14゚

2-

φ

3

5.8

3.4

4.5

6

13.7

1.2

R20

29

3.4

8.8

3.2

R25.4

39

1.2 3.5

16±0.1

■ENGINEERING DATA

200

150

100

50

0

-50

-100

-150

-200

Sensing Range

Y Operating Range [mm]

X Detection distance [m]

0123456

Y Mutual interference range [mm]

100

10

1

0.1

Excess Gain Ration

Excess gain ration

Distance [m]

024681012

Receiver

Emitter

Y

X

200

150

100

50

0

-50

-100

-150

-200

0123456

X Detection distance [m]

Mutual Interference Range

Receiver

Emitter

YX

SUITABILITY FOR USE

1. Read this instruction sheet thoroughly to understand before using the

product.

2. When used in combination with the F3SX safety controller, make

sure that the B1 module is properly connected.

3. A load must not be shorted. A load must not be used with current

higher than the rating. Do not apply the reversed supplied voltage.

Be sure to route the E3ZS cable separated from high-potential power

line or through an exclusive conduit.

4. Do not remove the label (yellow) from the sensor. Doing so may

violate the specifications.

5. Wire the cable so that it has some slack and does not prevent

personnel or object passage.

Allow some leeway for the wires and do not tight the wires when

connection cable to F3SX, and confirm that any cable may not block

the movements of workers or objects.

6. Do not disassemble, repair or modify the E3ZS.

7. Be sure to dispose of the E3ZS as industrial waste.

Precautions for Safe Use

●Alert Statements

WARNING

When the single beam safety sensor model E3ZS is used as a

safety device or a part of safety systems for ensuring safety of

personnel, be sure to use it with the safety controller model F3SX

series.

WARNING

If the mode selection input line of the receiver is connected to 0V,

the output turns ON when light is interrupted (Dark ON), which no

longer configures the safety system. Be sure to connect the mode

selection input line to 24V DC to make the sensor output ON when

light is incident (Light ON).

Always maintain a safe distance between the E3ZS and a

hazardous part of a machine. Be sure to refer to the related

standards (EN999) for the calculation of safety distance.

Use an opaque test rod with 18mm in diameter and 200mm or

greater in effective length to check the detection capability. The

E3ZS cannot detect transparent materials.

Do not use the E3ZS in a reflective configuration, otherwise

detection may fail.

Do not install the E3ZS in a location where it can be affected by

wall reflections to avoid detection failure, which may result in

serious injury.

When using multiple sets of E3ZS, arrange them to prevent mutual

interference. Failure to do so may cause the sensor not to detect,

resulting in serious injury.

The E3ZS does not offer protection to the operator’s body from

projectiles existing the hazardous area. Proper means of

mechanical guarding must be provided to ensure protection from

these potentially hazardous projectiles.

Wiring must be done while the power is turned OFF. Doing it with

the power ON may cause an electric shock.

Do not connect the E3ZS to an AC or DC power supply with higher

voltage than nominal DC24V. Otherwise the sensor may explode,

burn, or cause electric shock. The power supply must conform to

regulatory requirements and standards, regarding EMC and

electrical equipment safety, of the country where the E3ZS is

installed. For example, the power supply must fulfill EN60742

requirements for double insulation and must conform to EMC

Directive and Low Voltage Directive in EU.

Emitter

Receiver

Reflective

Panel

DIMENSIONS

Optical

axis

6.7dia

25.4

2.1

15.5

8

20

10.8

10.4

3.54

17

31

Lens

Vinyl insulated round cord

4dia, Emitter:3core, Receiver:4core

length 2m

Light emittion indicator(Emitter only)

Stability indicator(Receiver only)

Operation indicator(Receiver only)

2-M3

■RATINGS / PERFORMANCE

Through beam type

100ms

( )

( )

12 to 24V DC±10% (ripple p-p 10% max)

1.0ms (E3ZS only)

Response time depends on the F3SX.

For the details, see the users manual of the F3SX.

( )

22.5 to 24V DC : Emitting OFF

(Source current : 3mA max)

Open or 0 to 2.5 V DC : Emitting ON

(Leakage current : 0.1mA max)

When the E3ZS is used as a part of safe

apparatus or safe systems Category2(EN954-1),

use it with F3SX.

( )

Transistor output PNP, load current 100mA max

Output residual voltage of 1V or less

(when load current is less than 10mA)

Output residual voltage of 2V or less

(when load current is from 10 to 100mA)

(except for voltage drop due to cable extension)

When the E3ZS is used as a part of safe

apparatus or safe systems Category2(EN954-1),

use it with F3SX.

E3ZS

Illumination intensity

Incandescent lamp : 3000 lx max.

Sunlight : 10000 lx max.

Operating : -10〜55℃, Storage : -10〜70℃

(not freezing or condensation)

Operating : 35〜85% RH, Storage : 35〜95% RH

(not freezing or condensation)

Emitter : Orange / Light emission

Receiver : Green / Stability, Orange / Operation

Durability

Operation limit

Durability

Operation limit

When using E3ZS by itself:

EN954-1 (Category 1)

IEC60947-5-3 (PDF-D)

UL508

When E3ZS is connected to F3SX:

IEC61496-1 Type2 ESPE

IEC61496-2 Type2 AOPD

EN954-1 (Category 2)

UL508

UL61496-1 Type2 ESPE

UL61496-2 Type2 AOPD

・Instruction sheet

Model F3SX series

±5°(at 3m)

Emitter : 15mA max.

Receiver : 20mA max.

0.2~3m

Opaque object of

φ

18mm or more.

When the E3ZS is used as a part of safe

apparatus or safe systems Category2(EN954-1),

use it with F3SX.

Detection method

Controller

Power supply voltage

Operating angle

Current consumption

Sensing distance

Standard object

Response time

Control output

Power reset time

DC-13 (Control of electromagnets)

Utilization categories

for switching elements

Ambient illumination

Ambient temperature

Ambient humidity

Insulation resistance

Dielectric strength voltage

Enclosure ratings

Light source

Indicators

Circuit protection

Weight

Applicable

standards

Accessories

Vibration

resistance

Shock

resistance

Test Input

(Emitter)

20MΩor more (by 500V DC megger)

1000V AC, 50/60Hz for 1 min.

10〜55 Hz, 1.5mm double amplitude,

each X, Y, Z direction , 2 hours

10〜55 Hz, 0.7mm double amplitude,

each X, Y, Z direction , 50 min.

500m/s2(approx. 50G),

each X, Y, Z direction for 3 times

100m/s2(approx.10G),

each X, Y, Z direction for 1,000 times

IEC standard IP67

Red LED

Output short-circuit and power supply reverse polarity

Approx. 120g (1set)

■CIRCUIT DIAGRAM

●PNP output

Output mode : ON when incident (Light ON)

Output / Input circuit

Main

circuit

Stability

indicator

OrangeGreen

Operation

indicator

Connect to

24V DC terminal

Connect to cont

output terminal

Connect to 0V

terminal

(Note 1)

Brown

Brown

Pink

Pink

Black

Blue

Blue

(Note 1)

(Note 2)

(Note 1)

Main

circuit

Connect to

24V DC terminal

Connect to test

input terminal

Connect to 0V

terminal

(Note 1)

(Note 1)

(Note 3)

(Note 1)

(Note 1)・When the E3ZS is used as a part of safe apparatus or safe

systems Category2(EN954-1), connect to the B1 module of the

F3SX. Do not connect to the other modules.

・For the details, see the users manual of the F3SX.

(Note 2)・

Be sure to connect the ''Mode selection input'' to 24V DC terminal.

(Note 3)・When the E3ZS is used without being connected to F3SX, test

input should be connected to 0V.

Receiver

Emitter

Light emittion

indicator

■INFLUENCE OF REFLECTIVE SURFACES

Install the E3ZS with minimum distance D (given below) away from

reflective surfaces (highly reflective surfaces) such as metal walls, floors,

ceilings, and work pieces

Reflective Surfaces

5°

5°

D

L

Distance between emitter and

receiver

( Operating range L )

0.2 to 3 m

Minimum installation

distance D

0.27 m or more

No-load voltage

(V peak)

0 to 20

More than 20,

up to 30

Maximum current rating

(A)

5.0

100

Peak voltage value

1.Do not install the E3ZS in the following environments:

・Areas exposed to intense interference light, such as direct sunlight;

・Areas with high-humidity where condensation is likely to occur;

・Areas exposed to corrosive, flammable or explosive gases;

・Areas in the presence of substances, such as heavy smoke or

particulate matter, that may deteriorate product quality;

・Areas exposed to vibration or shock levels higher than specification

provisions;

・Areas where the product may come in direct contact with water, oil,

and chemicals;

2. Do not install the E3ZS in water.

3. To extend the cable, use a wire of cross-sectional area 0.3mm2or

more. However do not extend it more than 100m.

4. Be careful not to exceed a tightening torque of 0.5 Nm. Also, if it is

not tight enough, vibration may cause it to come loose.

5. When cleaning, avoid using thinner, benzene or acetone.

6. Power supply specifications

For combined DC power supply, use the following UL certified

products:

(1) Limited voltage current circuit that conforms to UL508

Circuit with a power supply that consists of a secondary coil of

an insulated transformer that satisfies the following conditions:

-

Maximum voltage(with no load)

: 30Vrms (42.4V peak) or less, and

-Maximum current :

8A or less (including short-circuit), or

When limited by a circuit

protector (fuse, etc.) with the

ratings shown in the table below

(2) Class 2 power supply unit that conforms to UL1310

(3) Circuit (class 2 circuit) with 30Vrms (42.4V peak) or less of

maximum voltage, and which uses a class 2 transformer that

conforms to UL1585 as its power supply

Precautions for Correct Use

●Meanings of Signal Words

Indicates a potentially hazardous

situation which, if not avoided, will

result in minor or moderate injury, or

may result in serious injury or death.

Additionally there may be significant

property damage.

WARNING

●Meanings of Alert Symbols

Indicates prohibited actions.

Precautions on Safety

・When the E3ZS is used with the F3SX, the requirements of the

Category 2 (EN954-1) are satisfied.

・When the E3ZS is used without the F3SX, it corresponds to the

Category 1 (EN954-1).

・Read the F3SX users manual (SCHG-705) about the rating or other

specifications of the F3SX.

TRACEABILITY INFORMATION:

Representative in EU:

Omron Europe B.V.

Wegalaan 67-69

2132 JD Hoofddorp,

The Netherlands

Manufacturer:

Omron Corporation,

Shiokoji Horikawa, Shimogyo-ku,

Kyoto 600-8530 JAPAN

Shanghai Factory

No.789 Jinji Road,

Jinqiao Export Processing District,

Pudong New Area,Shanghai,201206 CHINA

INSTRUCTION SHEET

Thank you for selecting OMRON product.This sheet pri-

marily describes precautions required in installing and

operating the product.

Before operating the product,read the sheet thoroughly to

acquire sufficient knowledge of the product.For your con-

venience,keep the sheet at your disposal.

The following notice applies only to products that carry the CE mark:

Notice:

This is a class A product. In residential areas it may cause radio

interference, in which case the user may be required to take adequate

measures to reduce interference.

OMRON Corporation

EUROPE

OMRON EUROPE B.V. Sensor Business Unit

Carl-Benz Str.4, D-71154 Nufringen Germany

Phone:49-7032-811-0 Fax: 49-7032-811-199

NORTH AMERICA

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg,IL 60173-5302 U.S.A.

Phone:1-847-843-7900 Fax : 1-847-843-7787

ASIA-PACIFIC

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road #05-05-08(Lobby 2),

Alexandra Technopark, Singapore 119967

Phone : 65-6835-3011 Fax :65-6835-2711

o

CHINA

OMRON(CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Phone : 86-21-5037-2222 Fax :86-21-5037-2200

OCT, 2009