CSM_XS5_DS_E_7_1

1

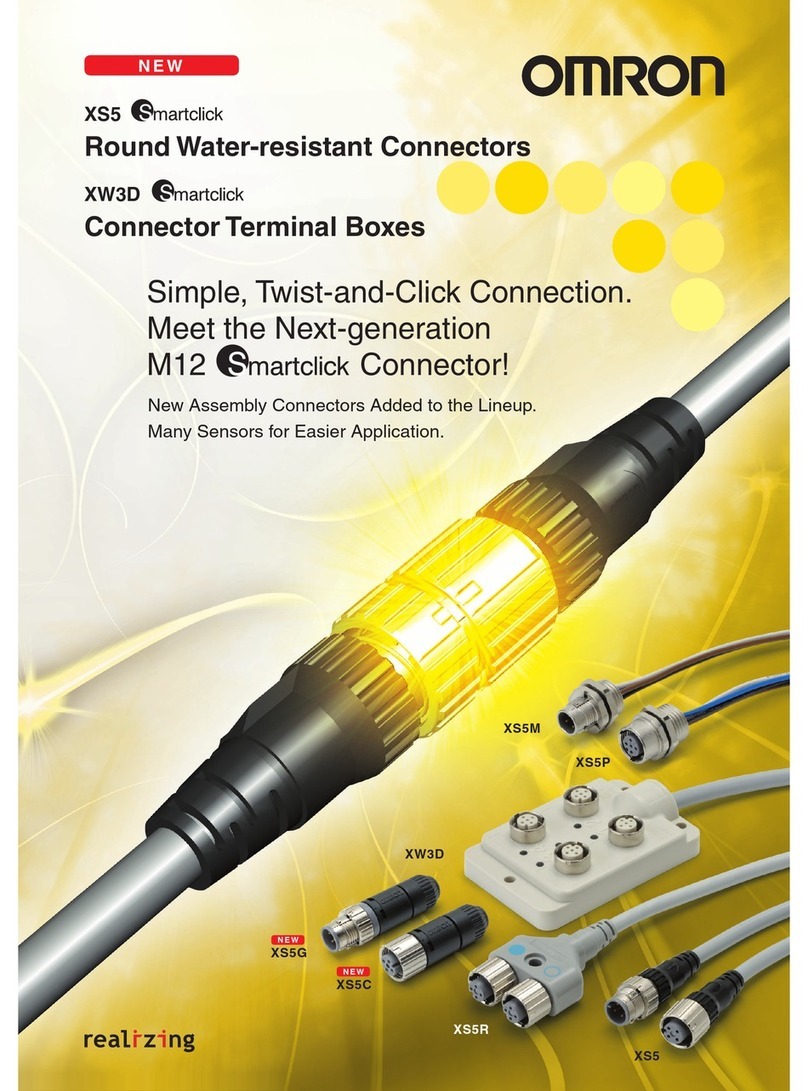

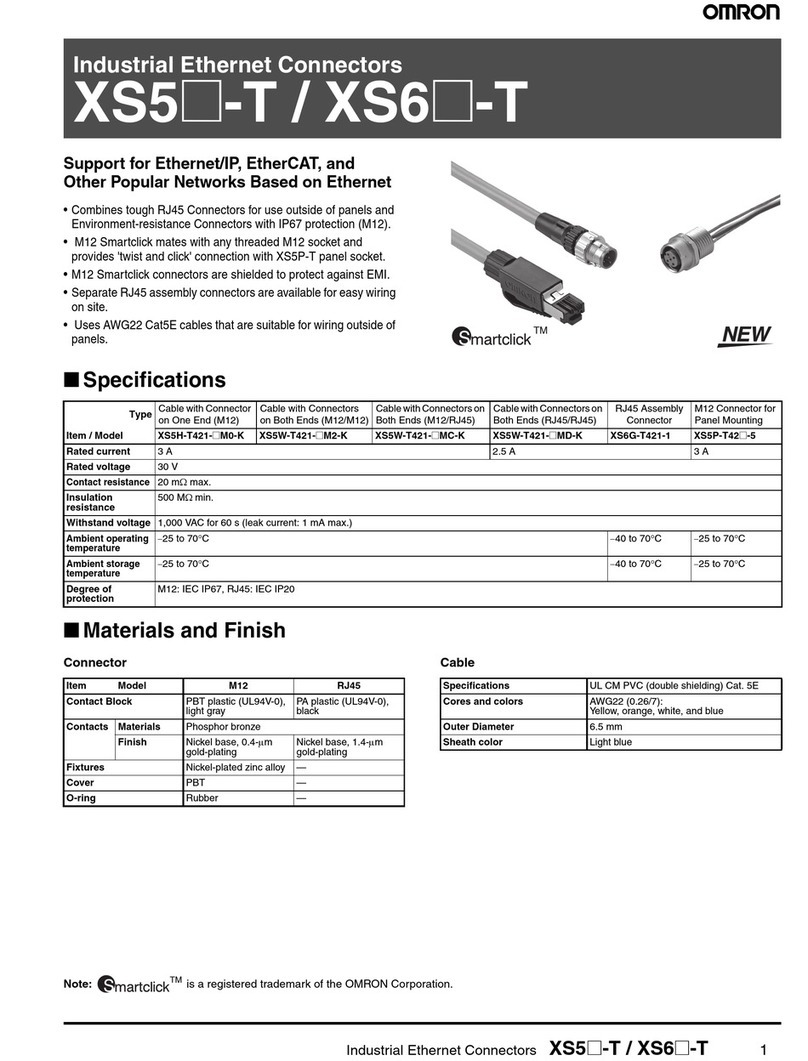

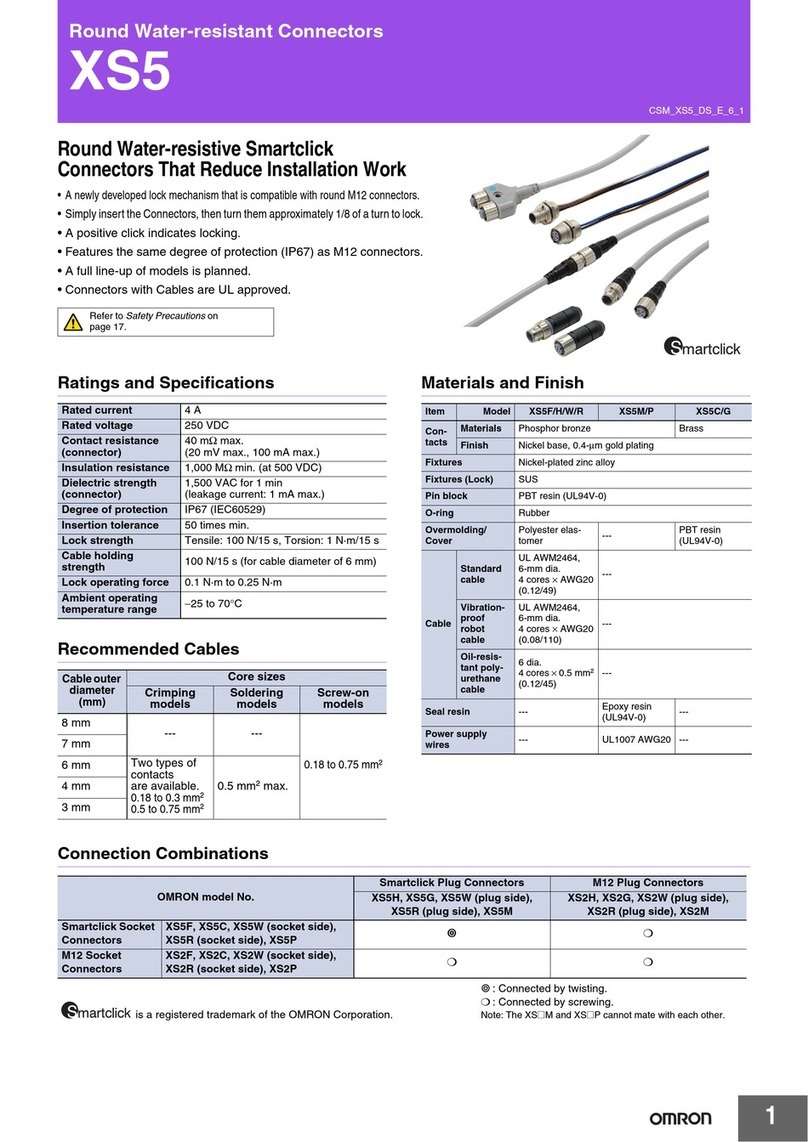

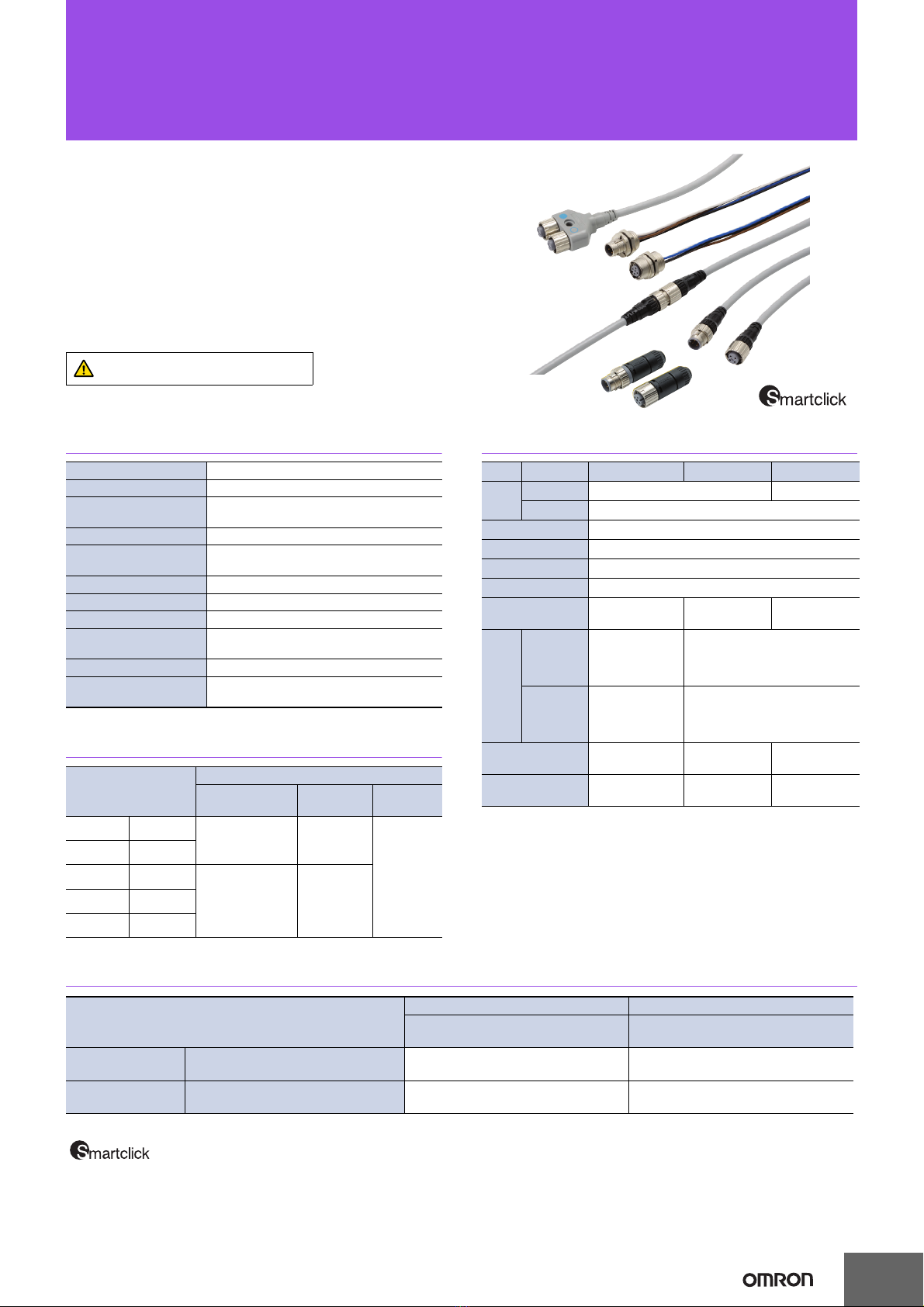

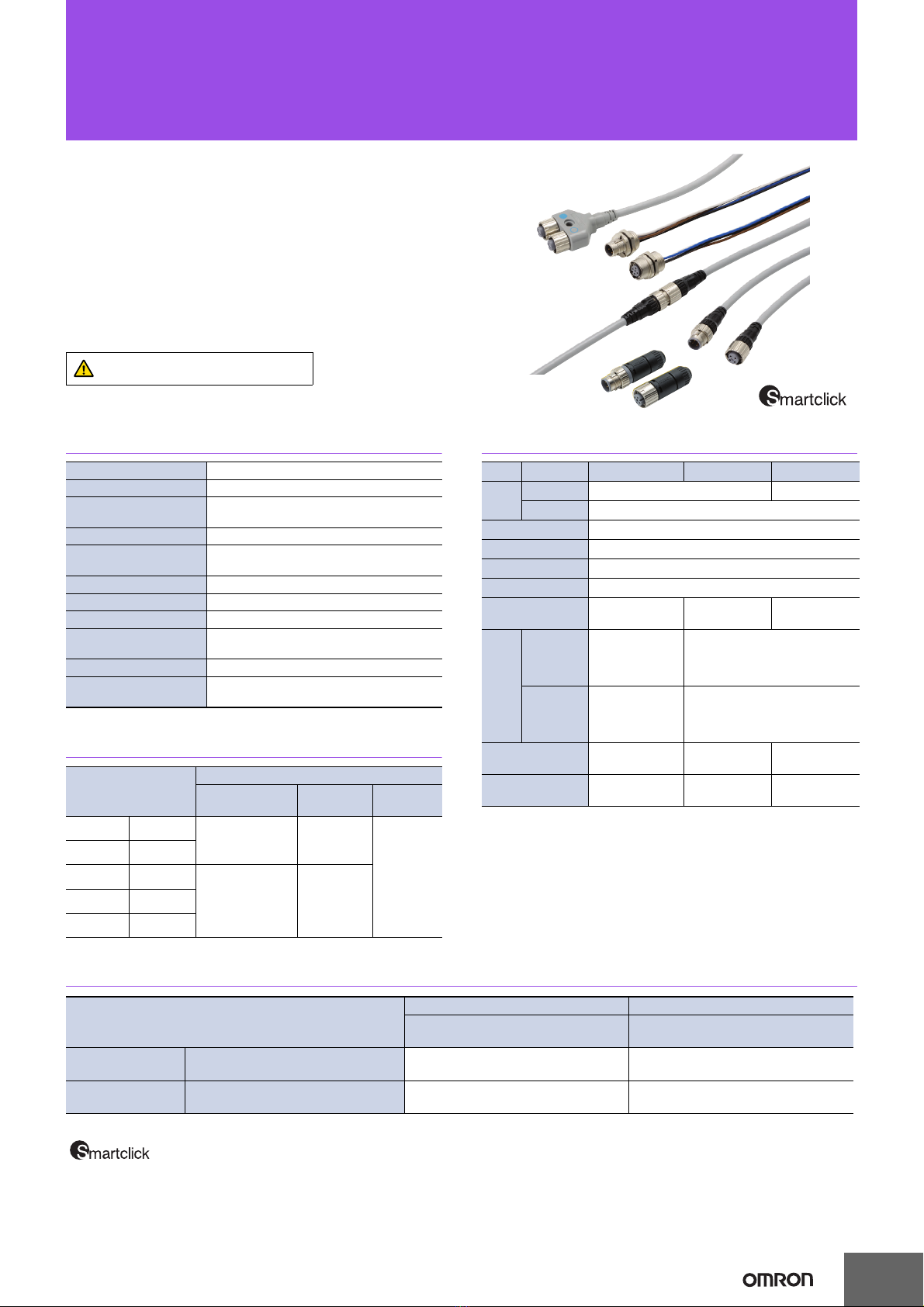

Round Water-resistant Connectors

XS5

Round Water-resistive Smartclick

Connectors That Reduce Installation Work

• A newly developed lock mechanism that is compatible with round M12 connectors.

• Simply insert the Connectors, then turn them approximately 1/8 of a turn to lock.

• A positive click indicates locking.

• Features the same degree of protection (IP67) as M12 connectors.

• A full line-up of models is planned.

• Connectors with Cables are UL approved.

Refer to Safety Precautions on

page 17.

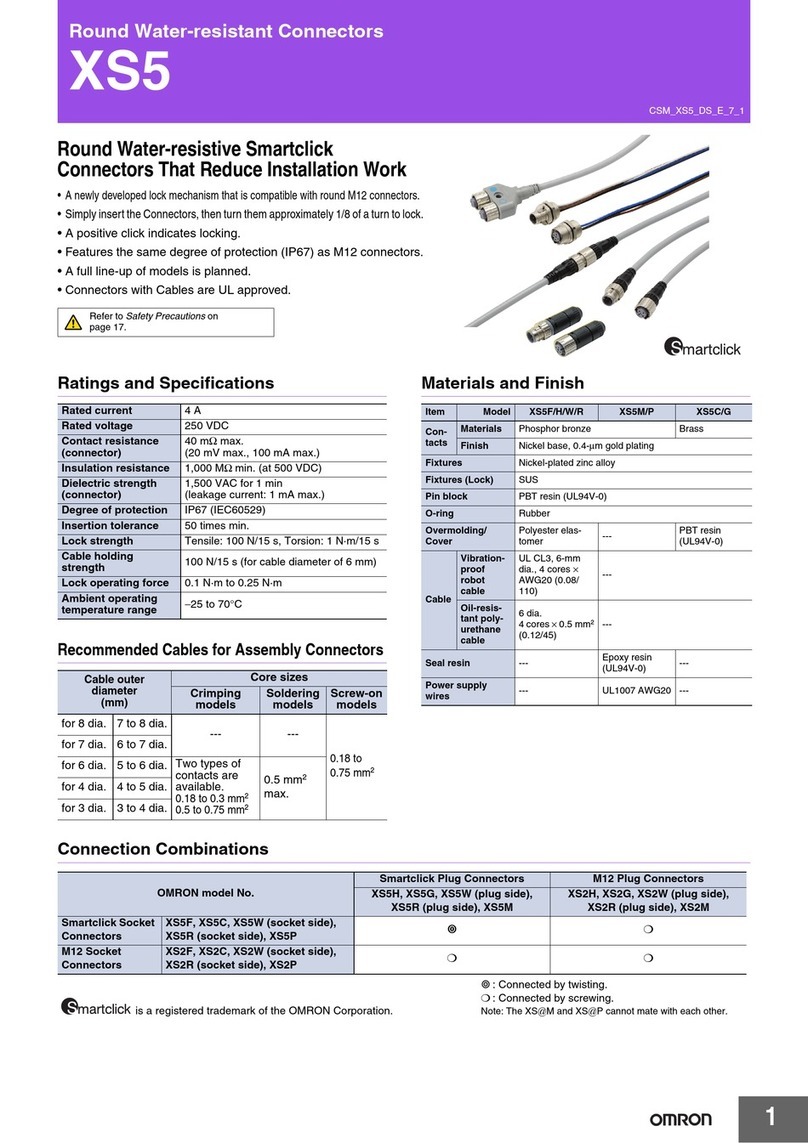

Ratings and Specifications

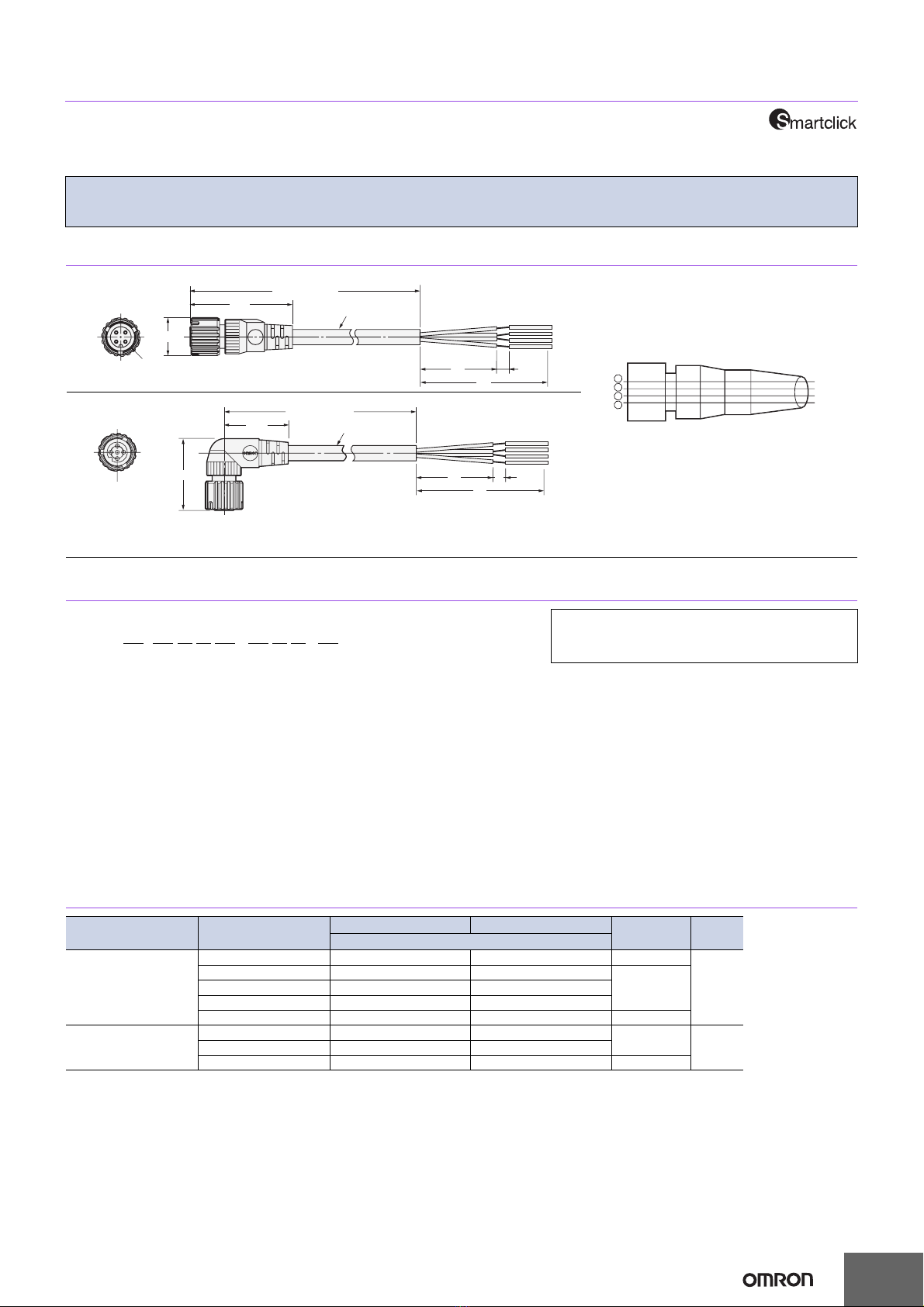

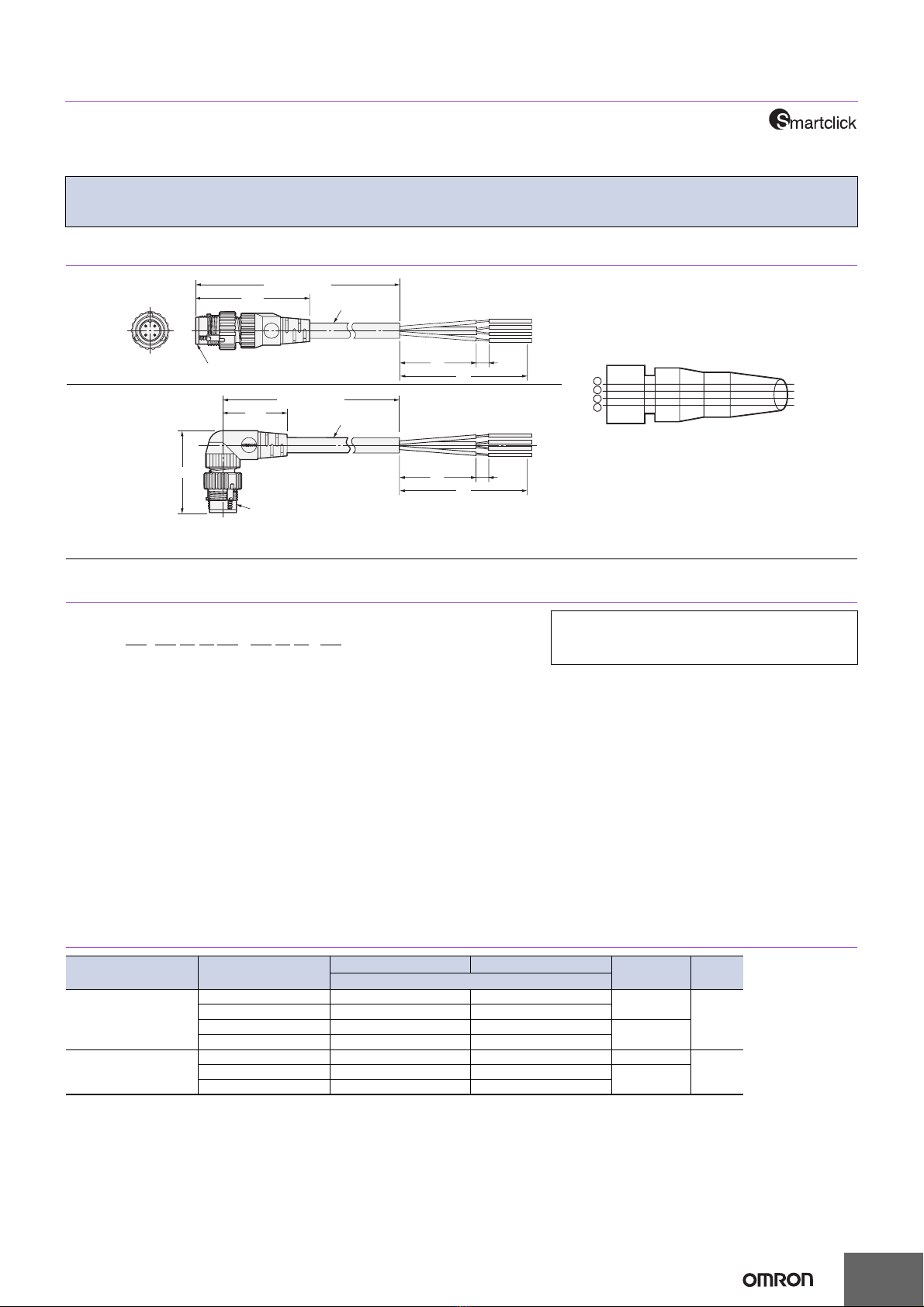

Recommended Cables for Assembly Connectors

Materials and Finish

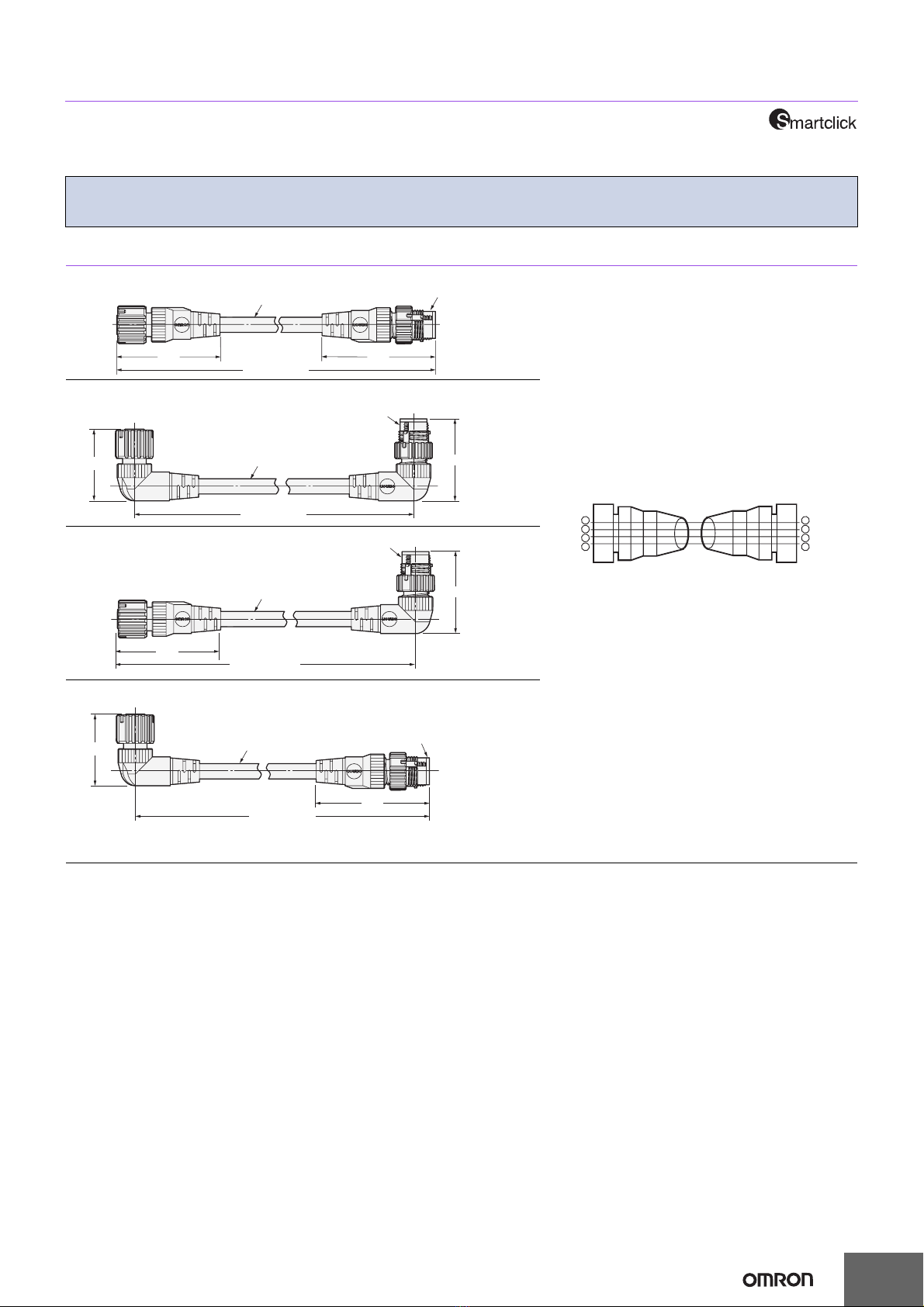

Connection Combinations

Rated current 4 A

Rated voltage 250 VDC

Contact resistance

(connector)

40 mΩmax.

(20 mV max., 100 mA max.)

Insulation resistance 1,000 MΩ min. (at 500 VDC)

Dielectric strength

(connector)

1,500 VAC for 1 min

(leakage current: 1 mA max.)

Degree of protection IP67 (IEC60529)

Insertion tolerance 50 times min.

Lock strength Tensile: 100 N/15 s, Torsion: 1 N·m/15 s

Cable holding

strength 100 N/15 s (for cable diameter of 6 mm)

Lock operating force 0.1 N·m to 0.25 N·m

Ambient operating

temperature range −25 to 70°C

Cable outer

diameter

(mm)

Core sizes

Crimping

models

Soldering

models

Screw-on

models

for 8 dia. 7 to 8 dia. --- ---

0.18 to

0.75 mm

2

for 7 dia. 6 to 7 dia.

for 6 dia. 5 to 6 dia. Two types of

contacts are

available.

0.18 to 0.3 mm

2

0.5 to 0.75 mm

2

0.5 mm2

max.

for 4 dia. 4 to 5 dia.

for 3 dia. 3 to 4 dia.

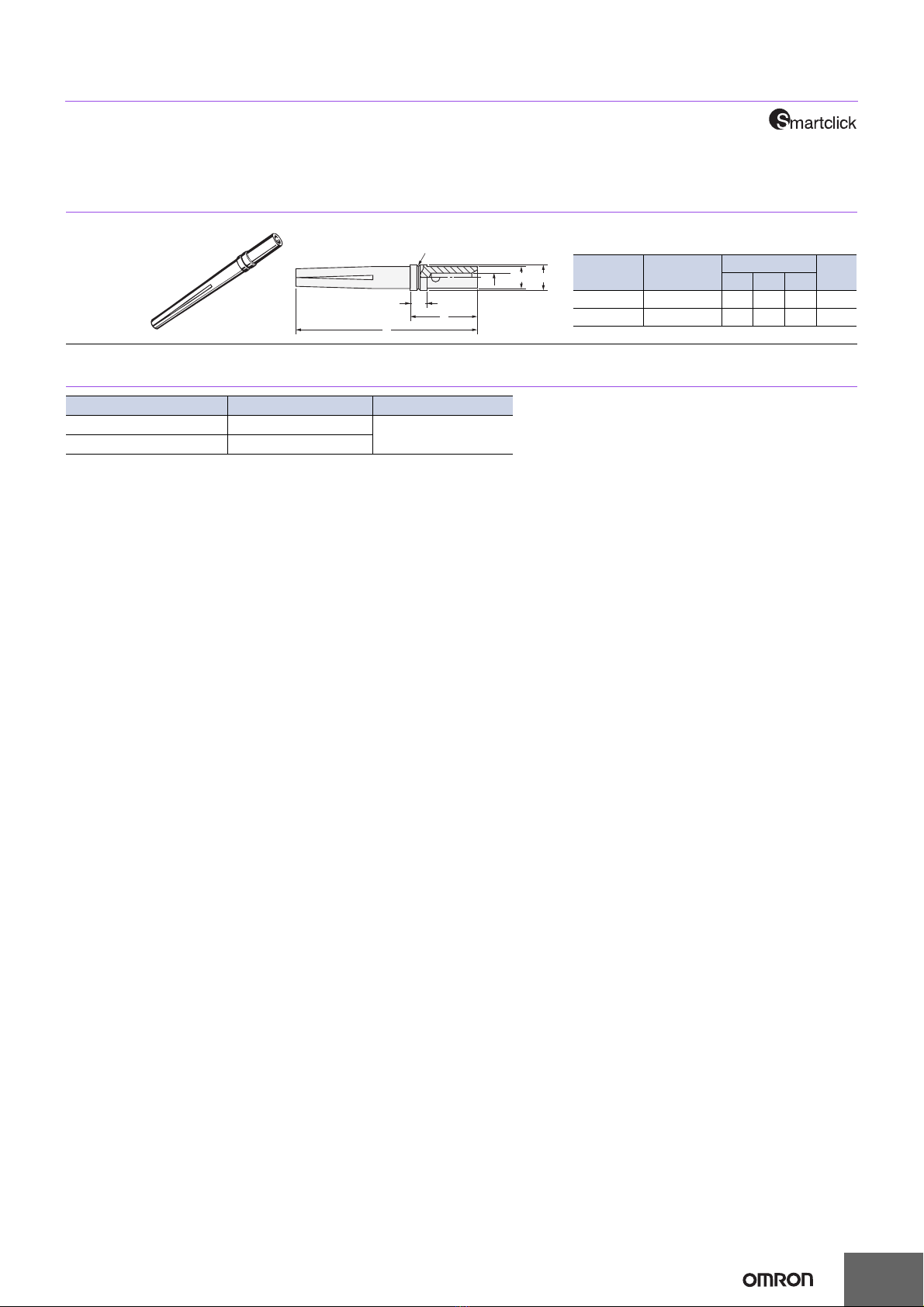

Item Model XS5F/H/W/R XS5M/P XS5C/G

Con-

tacts

Materials Phosphor bronze Brass

Finish Nickel base, 0.4-µm gold plating

Fixtures Nickel-plated zinc alloy

Fixtures (Lock) SUS

Pin block PBT resin (UL94V-0)

O-ring Rubber

Overmolding/

Cover

Polyester elas-

tomer --- PBT resin

(UL94V-0)

Cable

Vibration-

proof

robot

cable

UL CL3, 6-mm

dia., 4 cores ×

AWG20 (0.08/

110)

---

Oil-resis-

tant poly-

urethane

cable

6 dia.

4 cores ×0.5 mm2

(0.12/45)

---

Seal resin --- Epoxy resin

(UL94V-0) ---

Power supply

wires --- UL1007 AWG20 ---

is a registered trademark of the OMRON Corporation.

OMRON model No.

Smartclick Plug Connectors M12 Plug Connectors

XS5H, XS5G, XS5W (plug side),

XS5R (plug side), XS5M

XS2H, XS2G, XS2W (plug side),

XS2R (plug side), XS2M

Smartclick Socket

Connectors

XS5F, XS5C, XS5W (socket side),

XS5R (socket side), XS5P ❍

M12 Socket

Connectors

XS2F, XS2C, XS2W (socket side),

XS2R (socket side), XS2P ❍❍

: Connected by twisting.

❍: Connected by screwing.

Note: The XS@M and XS@P cannot mate with each other.