B-vi

Contents

Section 1 Description .........................................................................................................................................1

1-1 Features ......................................................................................................................................................1

1-2 Functions.....................................................................................................................................................2

1-2-1 Interlock function .................................................................................................................................2

1-2-2 Test function ........................................................................................................................................2

1-2-3 Auxiliary Output ...................................................................................................................................3

1-2-4 External indicator output......................................................................................................................3

1-2-5 EDM (External device monitoring).......................................................................................................4

1-2-6 Fixed blanking function (Optional).......................................................................................................4

1-2-7 Floating blanking function (Optional)...................................................................................................4

1-2-8 Detection zone ....................................................................................................................................5

1-2-9 Series connection................................................................................................................................5

1-2-10 Indicators...........................................................................................................................................6

1-3 Ratings and Performance ...........................................................................................................................7

1-3-1 Specification ........................................................................................................................................7

1-3-2 Response time...................................................................................................................................10

Section 2 Wiring and Mounting ........................................................................................................................11

2-1 Installation Conditions...............................................................................................................................11

2-1-1 Detection Zone and Intrusion Path....................................................................................................11

2-1-2 Safety Distance .................................................................................................................................12

2-1-3 Distances from Reflective Surfaces ..................................................................................................13

2-1-4 How to Prevent Mutual Interference..................................................................................................14

2-2 Dimensional Drawings ..............................................................................................................................16

2-2-1 Side mounting (e.g.: emitter).............................................................................................................16

2-2-2 Rear mounting (e.g.: emitter) ............................................................................................................19

2-3 Mounting ...................................................................................................................................................22

2-3-1 How to Mount the Unit.......................................................................................................................22

2-3-2 Dimensional Drawing of the Mounting Bracket .................................................................................23

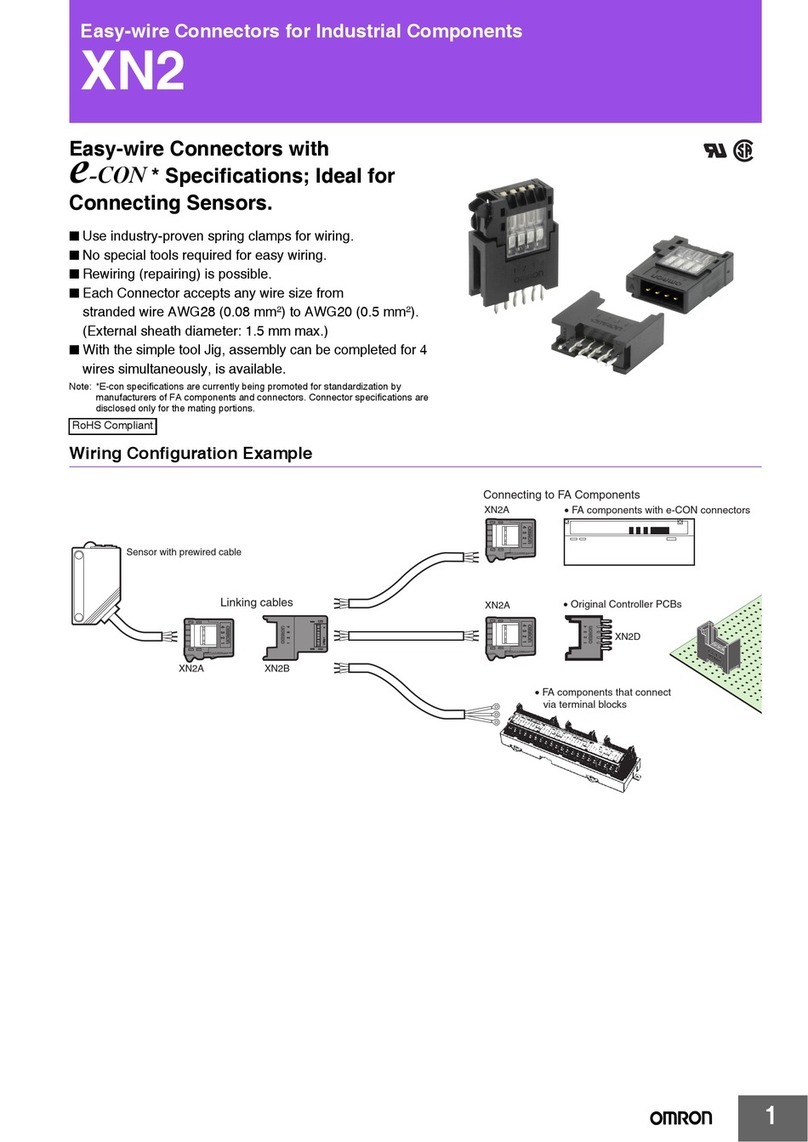

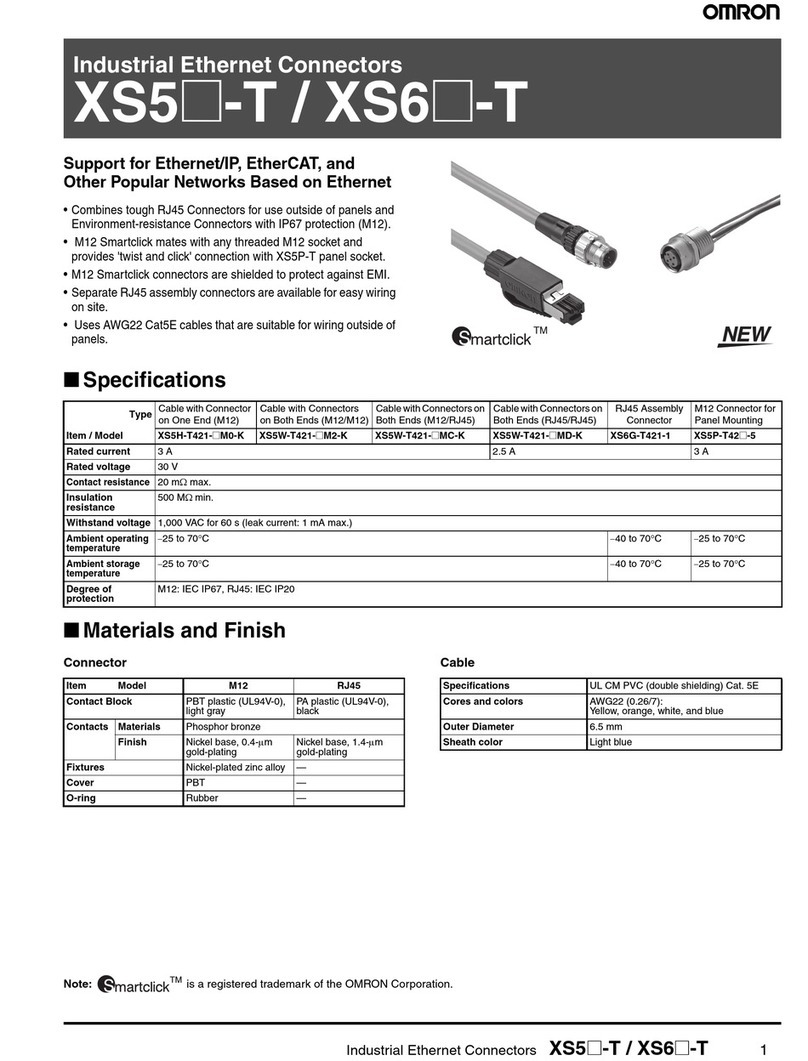

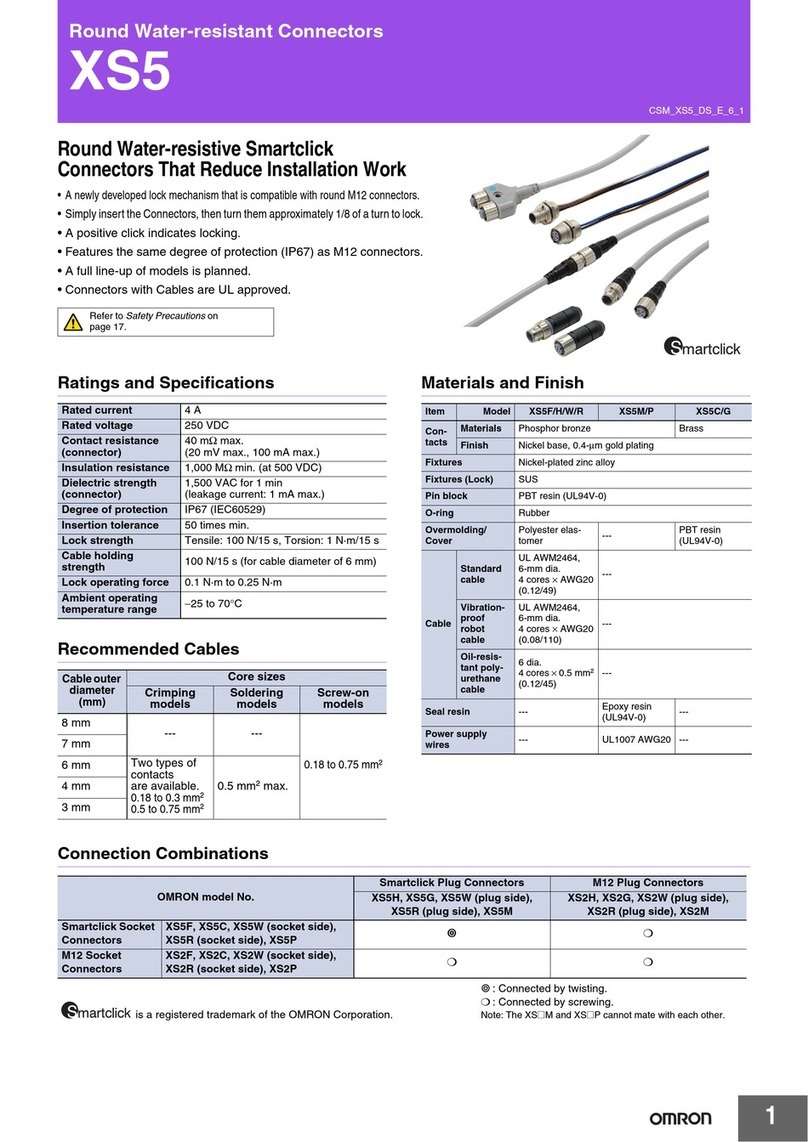

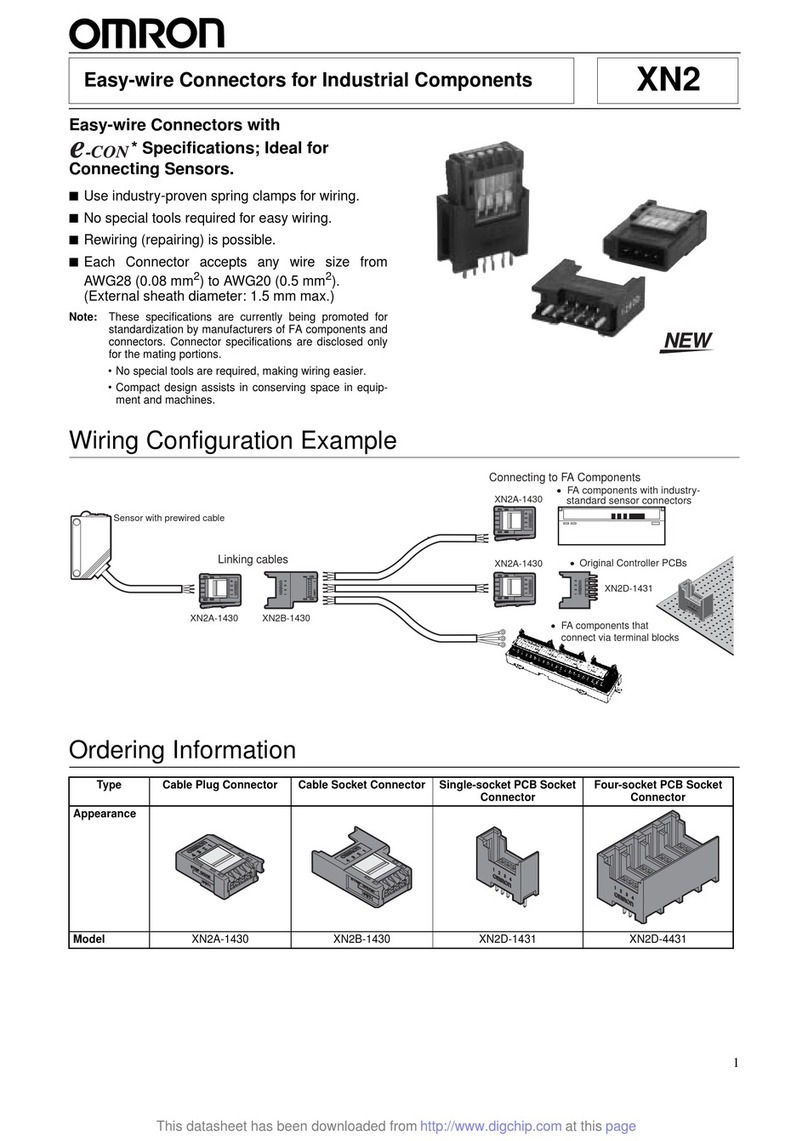

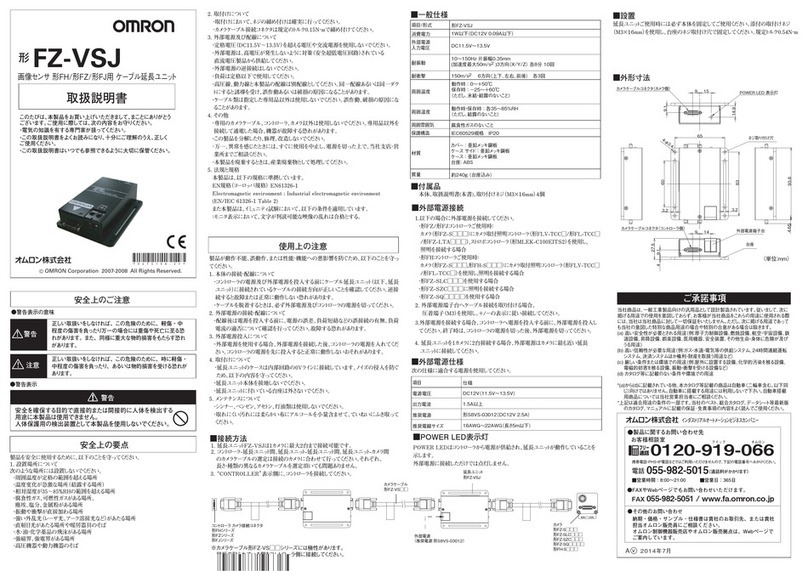

2-4 Wiring........................................................................................................................................................25

2-4-1 Power Supply Units ...........................................................................................................................25

2-4-2 Wiring Diagram..................................................................................................................................26

2-4-3 Wiring Procedures.............................................................................................................................28

2-4-4 Adjustment Procedures .....................................................................................................................30

2-5 Check List .................................................................................................................................................30

Section 3 I/O Circuit .........................................................................................................................................32

Section 4 Application........................................................................................................................................34

Section 5 Maintenance.....................................................................................................................................36

5-1 Daily Inspections .......................................................................................................................................36

5-2 Inspections Every Six Months...................................................................................................................37

Section 6 Troubleshooting ...............................................................................................................................38

6-1 Lockout condition ......................................................................................................................................38

6-2 Other trouble .............................................................................................................................................39

Section 7 Optional Accessory ..........................................................................................................................40

Section 8 Referenced standards......................................................................................................................42