7$%/( 2) &217(176

YLL

35(&$87,216 [L111111111111111111111111111111111

4,QWHQGHG $XGLHQFH [LL11111111111111111111111111111111111111111111111111111111111

5*HQHUDO 3UHFDXWLRQV [LL1111111111111111111111111111111111111111111111111111111111

66DIHW\ 3UHFDXWLRQV [LL11111111111111111111111111111111111111111111111111111111111

72SHUDWLQJ (QYLURQPHQW 3UHFDXWLRQV [LLL111111111111111111111111111111111111111111111

8$SSOLFDWLRQ 3UHFDXWLRQV [LLL111111111111111111111111111111111111111111111111111111

9(& 'LUHFWLYHV [YL11111111111111111111111111111111111111111111111111111111111111

6(&7,21 4

,QWURGXFWLRQ 4111111111111111111111111111111111111

404 &305& )HDWXUHV DQG )XQFWLRQV 5111111111111111111111111111111111111111111111

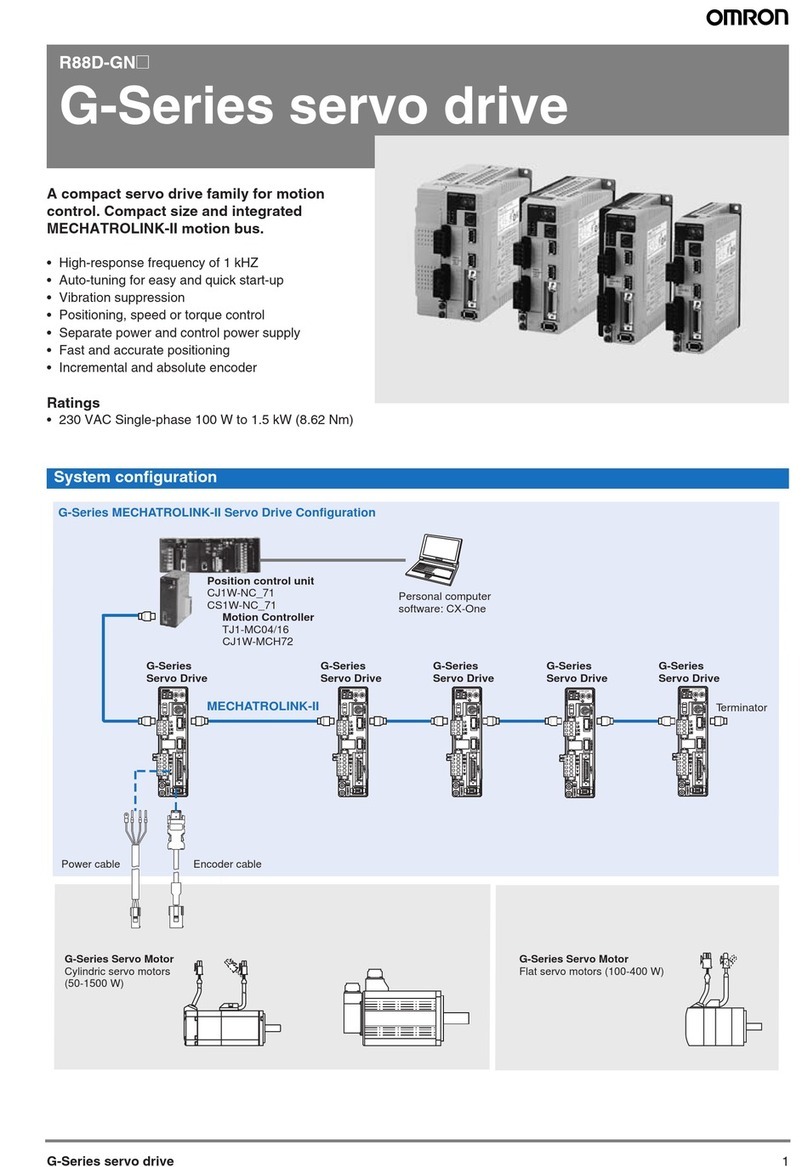

405 6\VWHP &RQILJXUDWLRQV 91111111111111111111111111111111111111111111111111111

406 6WUXFWXUH DQG 2SHUDWLRQ :111111111111111111111111111111111111111111111111111

407 )XQFWLRQV /LVWHG E\ 8VDJH 471111111111111111111111111111111111111111111111111

408 &RPSDULVRQ ZLWK WKH &304$DQG&305$49111111111111111111111111111111111111

409 3UHSDUDWLRQ IRU 2SHUDWLRQ 5511111111111111111111111111111111111111111111111111

6(&7,21 5

8QLW &RPSRQHQWV DQG 6SHFLILFDWLRQV 581111111111111111

504 8QLW &RPSRQHQWV 5911111111111111111111111111111111111111111111111111111111

505 6SHFLILFDWLRQV 6611111111111111111111111111111111111111111111111111111111111

6(&7,21 6

,QVWDOODWLRQ DQG :LULQJ 76111111111111111111111111111

604 'HVLJQ 3UHFDXWLRQV 771111111111111111111111111111111111111111111111111111111

605 6HOHFWLQJ DQ ,QVWDOODWLRQ 6LWH 7811111111111111111111111111111111111111111111111

606 ,QVWDOOLQJ WKH &305&7911111111111111111111111111111111111111111111111111111

607 :LULQJ DQG &RQQHFWLRQV 7;111111111111111111111111111111111111111111111111111

6(&7,21 7

8VLQJ 3URJUDPPLQJ 'HYLFHV :811111111111111111111111

704 6<60$&0&37 6XSSRUW 6RIWZDUH :91111111111111111111111111111111111111111111

705 6<60$& 6XSSRUW 6RIWZDUH +666,;6111111111111111111111111111111111111111111

706 8VLQJ D 3URJUDPPLQJ &RQVROH ;9111111111111111111111111111111111111111111111

707 3URJUDPPLQJ &RQVROH 2SHUDWLRQV <51111111111111111111111111111111111111111111

708 3URJUDPPLQJ ([DPSOH 4471111111111111111111111111111111111111111111111111111

6(&7,21 8

7HVW 5XQV DQG (UURU 3URFHVVLQJ 45411111111111111111111

804 ,QLWLDO 6\VWHP &KHFNV DQG 7HVW 5XQ 3URFHGXUH 455111111111111111111111111111111111

805 6HOI0GLDJQRVWLF )XQFWLRQV 45611111111111111111111111111111111111111111111111111

806 3URJUDPPLQJ &RQVROH 2SHUDWLRQ (UURUV 45911111111111111111111111111111111111111

807 3URJUDPPLQJ (UURUV 459111111111111111111111111111111111111111111111111111111

808 7URXEOHVKRRWLQJ )ORZFKDUWV 45;111111111111111111111111111111111111111111111111

809 0DLQWHQDQFH ,QVSHFWLRQV 46911111111111111111111111111111111111111111111111111

80: %DWWHU\ 5HSODFHPHQW 46:11111111111111111111111111111111111111111111111111111

$SSHQGLFHV

$ 6WDQGDUG 0RGHOV 46<11111111111111111111111111111111111111111111111111111111111

% 'LPHQVLRQV 4761111111111111111111111111111111111111111111111111111111111111111

,QGH[ 478111111111111111111111111111111111111111111

5HYLVLRQ +LVWRU\ 47<111111111111111111111111111111111