(3) Keep the product away from oil or solvent. Oil or solvent make

the marking on the product illegible and cause deterioration of

some parts.

(4) Do not use in an environment with corrosive gas.

(5) The product may not operate normally in the vicinity of devices

that generate strong radio waves or magnetic fields, such as

RFID systems, proximity sensors, motors, inverters, and

switch-mode power supplies. If the device is used in the

vicinity of such devices, check the effect before use.

(6) Installing the switch and the actuator on a metallic material

may affect the operating distance. If installation on a metallic

material is necessary, be sure to check the effect on the

operating distance before use.

(7) Tighten the screws with a specified torque.

(8) Use the wires specified by OMRON to wire the product.

(Refer to Connection.)

(9) Do not extend the cables in excess of the specification of this

product. Carry out electrical connection according to the wiring

examples shown in this document and verify the correct

operation of the product.

(10)

During installation, make sure that the safety door switch does

not come in contact with the actuator due to rattling of the

guard door. (The performance of the product may be degraded

by a collision caused by opening or closing the guard door.)

(11) Do not pull or bend the cable excessively. A disconnection

may cause a malfunction.

(12) Risk time remains unchanged by series connection. However,

carry out electrical connection according to the wiring

examples shown in this document.

(13)

Be sure to inspect the product daily and every 6 months.

Failure to do so may cause a system failure and serious injury.

(14)

When determining the safety distance, take into account the

delay of the output of the product caused by the response time.

Failure to do so may cause the operator to reach the hazardous

source before the machine is stopped, resulting in serious injury.

(15) Install the product so that the LED indicators of the safety

door switch are as visible as possible. Misinterpreting the

status of the safety door switch may result in danger.

(16) Do not use the product at an altitude of 2,000 m or higher.

(17) Do not connect a product different from this product in series

with this product. Doing so may disturb waveforms of the

input and output signals, leading to loss of the safety function.

(18) Do not use the product in the water or continuous water

exposure environment. Doing so may cause water to leak into

the product. (The degree of protection does not guarantee the

protection under continuous water exposure environment.)

(19) Do not tamper the product with a replacement actuator. Store

replacement actuators in a safe place where they cannot be

easily reached.

(20) Build a safety system using the outputs of both Safety

Outputs 1 and 2. Wiring with only one safety output may lead

to loss of the safety function due to a single failure.

(21) Wiring should meet the requirements specified in Section

9.4.3 of IEC 60204-1 to prevent malfunction due to ground

faults in the safety output lines.

(22)

Do not wire the product to an input of a safety controller in parallel.

(23) Do not try to disassemble, repair, or modify the product.

Doing so may cause loss of the safety function.

(24) Do not operate the product in an environment with flammable

or explosive gas.

(25)

After installation of the product, qualified personnel should verify

to see that the installation, inspection, and maintenance are

properly performed. The qualified personnel should be qualified

and authorized to secure the safety on each phase of design,

installation, running, maintenance and disposal of system.

(26) Auxiliary output is NOT a safety output. Do not use the

Auxiliary output individually for any safety function. Such

incorrect use causes loss of the safety function of the product

and its relevant systems.

(27) Disconnect the product and the controller connected to the

product from power supply when replacing the product.

Failure to do so may cause unexpected operation of devices

connected to the product.

(28)

The safety function may not operate normally due to a

malfunction of the wiring, setting, or switch, and the machine may

continue to operate, which may result in personal injury. Make

sure that the safety function works before starting operation.

(29) Do not use the product as a door stopper. (The performance

of the product may be degraded due to a collision caused by

opening and closing the guard door.)

(1) Do not drop the product to the ground or expose to excessive

vibration or mechanical shocks. Doing so may damage the

product and cause failure.

(2) Do not store or use the product under the following conditions.

Doing so may damage the product and cause failure.

1)

At ambient operating temperatures out of the range of -25 to 65°C

2)

At ambient storage temperatures out of the range of -25 to 85°C

3) At relative humidity of 93% or more

4) In direct sunlight

5) Under drastic temperature changes

6) In high humidity that causes condensation

Operating distance

The side allows for a maximum height misalignment (X) of safety

door switch and actuator of ±8 mm (e.g. mounting tolerance or due

to guard door sagging). The axial misalignment (Y) is max. ±18 mm.

Actuating curves

The actuating curves represent the typical operating distance of

the safety door switch during the approach of the actuator subject

to the actuating direction.

The continuous signal of the yellow LED signals the actuator

detection; the flashing of the yellow LED signals that the safety door

switch is actuated in the different travel area.

Preferred actuation directions: from front or from side

In case of a lateral actuation, the operating distances are reduced

by approx. 3 mm.

Recommended Adjustment

Align the safety door switch and actuator at a distance of 0.5 x

assured operating distance (Sao).

The correct functionality of both safety channels must be checked

by means of the connected safety controller.

The mounting holes provide for a mounting by means of M4 screws

(max. tightening torque 0.8 N•m). The product can be mounted in any

position. The minimum bend radius of the -025-type cable is 25 mm.

The active areas of the safety door switch and the actuator have to

face each other. The safety door switch must only be used within the

assured operating distances ≤ Sao and ≥ Sar.

To avoid any interference inherent to this kind of system and any

reduction of the operating distances, please observe the following

guidelines:

•

See the figures below for the minimum distances between two safety

door switches and other systems of the same frequency (125 kHz).

Sealing Kit (D41D-SK)

Contents: 4 flat plugs and 4 plugs with rim for high screw head

Purpose: Used to seal the mounting holes

Mounting Kit (D41D-MS)

Contents: 2 mounting plates and 4 ferrule plugs

Purpose (Mounting plate): Used to fix to a non-flat surface such as a

profile.

Purpose (Ferrule plug): Used for applications with considerable

changes in ambient temperature.

Note: 1. Lateral actuation only from the shown side of the safety door switch.

Note:1. If multiple safety door switches are involved in the same

safety function, the PFH values of the individual

components must be added.

For use in NFPA 79 Applications.

Adapters providing field wiring means are available from the

manufacturer. Refer to manufacturer's information.

For use in Pollution Degree 2 Environment.

Safety classification information

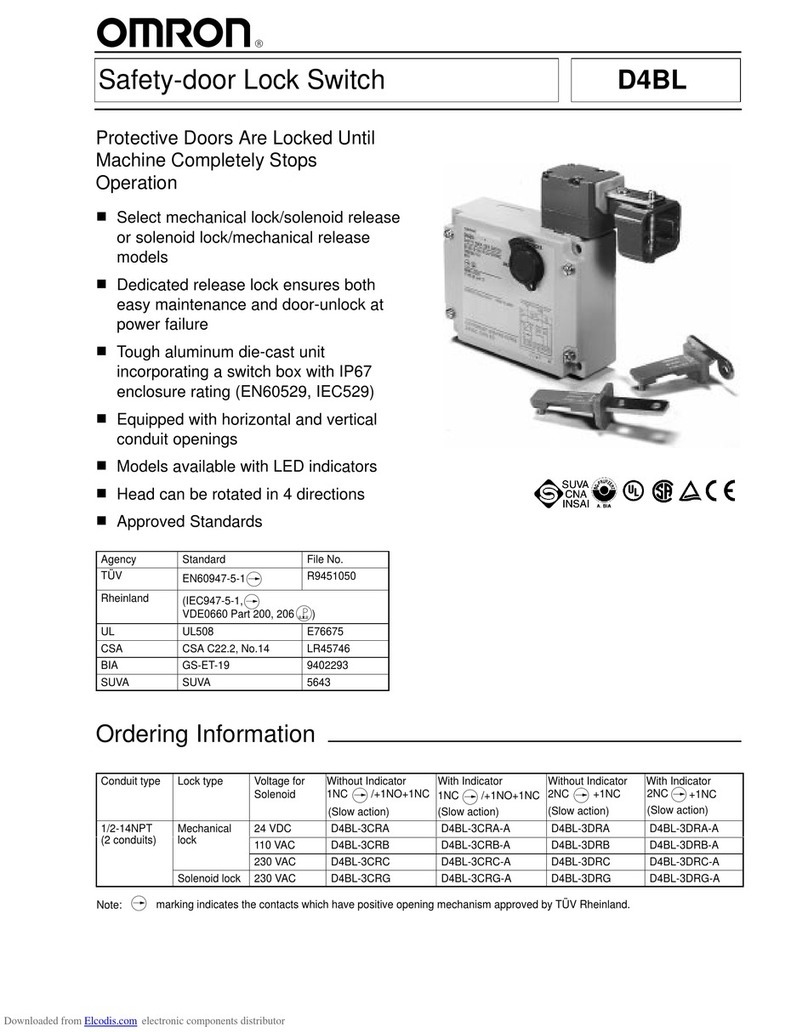

High-Coded Safety Door Switch

5673883-0A

Thank you for purchasing Omron products. This

product is a high-coded safety door switch.

Please read and understand this document

before using the products. Keep this document

ready to use whenever needed. Only qualified

person trained in professional electrical

technique should handle the product. Please

consult your Omron representative if you have

any questions or comments. Make sure that

information written in this document are

delivered to the final user of the product.

Model D41D

Safety Precautions

Indicates a potentially

hazardous situation which, if

not avoided, will result in

minor or moderate injury, or

may result in serious injury or

death. Additionally there may

be significant property

damage.

Alert Statements

Precautions for Correct Use

Detection Range (Typical Data)

EN Instruction Manual

EU Declaration of Conformity

Standards

OMRON declares that the D41D is in conformity with the

requirements of the following EU Directives:

Machinery Directive 2006/42/EC

RE Directive 2014/53/EU

The D41D High-Coded Safety Door Switch is designed for

safety circuits and is used to monitor the position of movable

guards.

D41D is designed and manufactured in accordance with the

following standards:

• EN ISO 13849-1: 2015 PL e Category 4

• EN 60947-5-3

• EN 300 330

• EN ISO 14119

• IEC 61508

• EN 62061

©OMRON Corporation 2021 All Rights Reserved.

WARNING

WARNING

(1) Disconnect the product from power supply

when wiring the product. Failure to do so may

cause unexpected operation of devices

connected to the product.

(2) Wire the input and output terminals correctly

and verify the correct operation of the product

before using the system in which the product

is incorporated. Incorrect wiring may lead to

loss of the safety function.

(3) Do not use the product in any direction other

than the specified mounting orientations of

the main body and actuator.

(4) Dispose of the product in accordance with the

laws set by each country.

Precautions for Safe Use

Actuator Mounting Direction

Ratings and Specifications Dimensions

Mounting

Accessory

Actuation from front

[Unit: mm]

[Unit: mm]

[Unit: mm]

active area

Safety door switch

Actuator

D41D-*CD-N1

Actuation from side

Y

X

Transverse misalignment

-5-20 5 1510-15 20-10 0

Y [mm]

S [mm]

0

5

10

12

Height misalignment

-5-20-24 5 10 15-15 20 24-10 0

X[mm]

S [mm]

0

5

10

12

Standard ISO 13849-1, IEC 61508, IEC 62061

e

99 %

4

6.8 x10-10/h

1.2 x 10-4

Suitable for SIL3 applications

20 years

PL

DC

Safety category

PFH (number)

PFD

SIL

Mission time

19

10.5

22

39.2

47.5 LED indications

18

M4

D41D-*CD-025N2

432547 250±10

D41D-A1: M4 screw

(Tightening torque: 0.8 N•m)

D41D-A2 : M5 screw

(Tightening torque: 2 N•m)

D41D-A3 : M3 screw

(Tightening torque: 0.6 N•m)

19

10.5

39

22

18

M4

12

12

16

15

18

12

18

This device complies with part 15 of the FCC Rules and Industry

Canada license-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including

interference that may cause undesired operation.

This device complies with the Nerve Stimulation Exposure Limits

(ISED RSS-102) for direct touch operations. Changes or

modifications not expressly approved by OMRON Corporation

could void the user‘s authority to operate the equipment.

Le présent appareil est conforme aux CNR d'Industrie

Canada applicables aux appareils radio exempts de licence.

L'exploitation est autorisée aux deux conditions suivantes:

(1) l'appareil ne doit pas produire de brouillage, et

(2) l'utilisateur de l'appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d'en

compromettre le fonctionnement.

Cet appareil est conforme aux limites d‘exposition relatives à la

stimulation des nerfs (ISED CNR-102) pour les operations

tactiles directes. Changements ou modifications non

expressément approuvés par OMRON corporation pourrait

annuler le droit de l‘utilisateur à utiliser l‘équipement.

Dispose in accordance with applicable regulations.

Make sure that the DC power supply meets the

following items. Failure to do so may result in

serious injury or death.

- Satisfies the requirements of PELV power

supply defined in IEC 60204-1.

- Satisfies the requirements of class 2 circuits

defined in UL508.

When complying with safety standards, install

the product in an appropriate manner in

accordance with ISO 14119, with due

consideration of the risk of defeat by the

operator. Failure to do so may result in serious

injury or death.

Install the switch and actuator in a position

where the opening of the guard door can be

detected within a safe distance. Failure to do so

may result in serious injury or death.

Do not apply DC voltages exceeding the rated

voltages, nor any AC voltages to the product.

Failure to do so may result in serious injury or

death.

Use only appropriate components or devices

complying with relevant safety standards

corresponding to the required performance

level and safety category. Failure to do so may

result in serious injury or death. Conformity to

requirements of the performance level and

safety category must be determined as an

entire system. It is recommended to consult a

certification body regarding assessment of

conformity to the required safety level.

*1. Refer to the product catalog for connection specifications with the

controller.

D41D

RFID

125 kHz

Type 4

D41D-1: High (individual coding)

D41D-2: High (individual coding re-teaching enabled)

-6 dBm max.

100 ms max.

200 ms max.

2 s max.

D41D-A1, D41D-A2, D41D-A3

12 mm

(lateral actuation: 9mm)

10 mm (-10 to 60°C)

6 mm (-10 to 60°C, lateral)

8 mm (-25 to 65°C)

4 mm (-25 to 65°C, lateral)

18 mm

(lateral actuation: 15 mm)

<2.0 mm

<0.5 mm

35 mA

III

3

(UL certification is 2)

24 VDC (-15%/+10%)

(stabilized PELV-power supply)

100 A

Pollution degree

Supply voltage (Ue)

Conditional short-circuit current

Test pulse interval

1.0 ms max.

Current

consumption

per input

5 mA

Safety output

Switching element

PNP type, short-circuit proof

(OSSD) DC-12: 24 VDC (Ue)/0.25 A (Ie)

DC-13: 24 VDC (Ue)/0.25 A (Ie)

Operating current

(Ie1) 0.25 A max.

Voltage drop (Ud) <1 V

Test pulse duration

1.0 ms max.

Test pulse interval

1,000 ms

Switching element

PNP type, short-circuit proof

DC-12:24 VDC (Ue)/0.05 A (Ie)

DC-13:24 VDC (Ue)/0.05 A (Ie)

Operating

current (Ie2)

0.05 A max.

Voltage drop (Ud) <2 V

100 ms min.

Utilization category

Auxiliary

output Utilization

category

Safety input Accepted test

pulse duration

on input signal

1 Hz

32 VDC

0.8 kV

<0.5 mA

0.5 mA

Minimum operating current (Im)

Switching frequency (f)

Rated insulation voltage (Ui)

Rated impulse withstand

voltage (Uimp)

OFF-state leakage current (Ir)

Current consumption (Io)

Overvoltage category

-25 to 65°C

-25 to 85°C

93% max.

(non-condensing, non-icing)

IP65 and IP67

10 to 55 Hz, amplitude 1.0 mm

30 g/11 ms

Ambient operating temperature

Ambient storage temperature

(including during transportation)

Ambient operating humidity

Degree of protection

(IEC 60529)

Vibration resistance

Shock resistance

Assured switch-off distance

(Sar)

Differential travel

Repeat accuracy (R)

Typical operating distance

(Sn)(IEC 60947-5-3)

Assured operating distance

(Sao)

(IEC 60947-5-3)

Transmitter outputs

Response time (ON to OFF)

Risk time

Startup time

Actuator

31 max. (*1)

100m max.

(between switch and power supply)

Cable lengths

Connection

Series connection

Model

Fixing screws

Thermoplastic PBT (enclosure)

2×M4

(Refer to the outline drawing for the actuator)

0.8 N•m

(Refer to the outline drawing for the actuator)

Tightening torque of fixing

screws

Material

Detection method

Frequency band

Interlock type (ISO 14119)

Coded level (ISO 14119)

Technical

Electrical

Connection

Environmental

Weight Unit: <50 g, Packaged: <110 g

External device fuse rating

Mechanical

2 A max.

Original Instructions

D41D-1CD-N1: Connector plug M8,

8-pole, A-coded

D41D-2CD-025-N2: Connecting cable

0.25-m long with connector M12

50

109

90

100

60

6.8

40

16

M5

22

4

3

9

M3

4

1.2 dia.

6 dia.

7

15

16.5

[Unit: mm]

12

4

12

4

12

9

7

29

29