F-58 Two-circuit Limit Switch WL

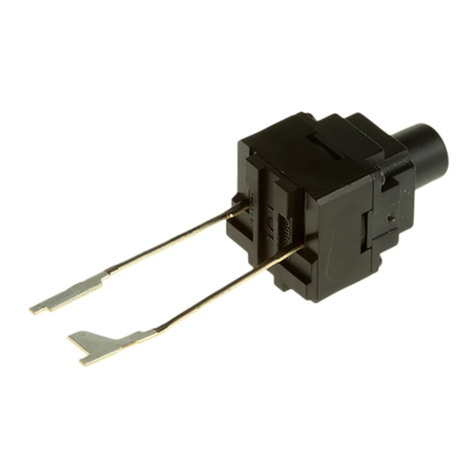

Symbol Actuator type Switches without levers

SD2 Plunger: Horizontal-roller plunger ---

SD3 Plunger: Horizontal-ball plunger ---

NJ Flexible rod: Coil spring ---

NJ-30 Flexible rod: Coil spring, multi-wire ---

NJ-2 Flexible rod: Coil spring, resin rod ---

NJ-S2 Flexible rod: Steel wire ---

3. Environment-resistant Model Specifications

Blank: Standard

RP: Corrosion-proof (See note 1.)

P1: Weather-resistant (See note 1.)

4. Built-in Switch Specifications

Blank: General-purpose built-in switch

55: Hermetically-sealed built-in switch (See note 1.)

5. Temperature Specifications

Blank: Standard: –10°C to 80°C

TH: Heat-resistive: 5°C to 120°C (See note 1.)

TC: Low temperature: –40°C to 40°C (See note 1.)

6. Special Hermetic Model Specifications

Blank: No cables or molding

139: General-purpose built-in switch with cables attached and molded conduit opening and cover (cover cannot be removed).

(See note 1.)

140: Airtight built-in switch with cables attached and molded conduit opening, cover, and case cover (cover cannot be removed).

(See note 1.)

141: Airtight built-in switch with cables attached and molded conduit opening, cover, and case cover (cover cannot be removed).

The Head opening is created to protect it from cutting powder. (See note 1.)

145: Airtight built-in switch with cables attached and molded conduit opening, cover, and case cover (cover cannot be removed, Head

can be mounted in any of 4 directions).

The Head opening is created to protect it from cutting powder. (See note 1.)

RP40: Airtight built-in switch with cables attached, SC Connector can be used, molded conduit opening, cover, and case cover

(cover cannot be removed, Head direction can be changed). (See note 1.)

RP60: Airtight built-in switch with cables attached, fluorine rubber-molded conduit opening, cover, and case cover

(cover cannot be removed, Head direction cannot be changed). (See note 1.)

7. Conduit Size, Ground Terminal Specifications (See note 2.)

Blank: G 1/2Without ground terminal

G1: G 1/2With ground terminal

G: Pg13.5 With ground terminal

Y: M20 With ground terminal

TS: 1/2-14NPT With ground terminal

8. Indicator Type

Element Voltage Leakage Current

LE: Neon lamp 125 VAC Approx. 0.6 mA

250 VAC Approx. 1.9 mA

LD: LED 10 to 115 VAC/VDC Approx. 0.5 mA

9. Lamp Wiring

2: NC connection: Light-ON when operating

3: NO connection: Light-ON when not operating

10.Lever Type

Blank: Standard lever

A: Double nut lever

Note: 1. For information on applicable models, see page 60.

2. Switches with ground terminals meet EN/IEC standards (and have the CE marking).

Ground Terminal Models 1: Type of actuator

2: Conduit opening size

The models differ depending on the size of the case’s conduit thread.

12

WL -

Model Conduit opening size

G1 G 1/2

G Pg 13.5

YM20

TS 1/2-14NPT