OMS DUKE EASY manual

DUKE EASY S.T.01/3AW Rev.0 01/2017

Instruction handbook

Dental Unit

DUKE EASY

DUKE EASY S.T.01/3AW Rev.0 01/2017

2

DUKE EASY S.T.01/3AW Rev.0 01/2017

3

ENGLISH (Translation of the original instructions)

1. GENERAL INFORMATION ..................................................................................................................................5

SAFETY........................................................................................................................................................................................6

ADMITTED ENVIRONMENTAL CONDITIONS............................................................................................................7

WARRANTY................................................................................................................................................................................8

2. TECHNICAL SPECIFICATIONS ........................................................................................................................9

3. TECHNICAL INSTRUCTIONS FOR INSTALLATION................................................................................11

PACKAGING.............................................................................................................................................................................. 11

ASSEMBLY................................................................................................................................................................................12

CONNECTIONS......................................................................................................................................................................13

TESTING AND PUTTING INTO OPERATION............................................................................................................13

4. CONTROLS - ADJUSTMENTS - INDICATORS .......................................................................................... 15

SAFETY SYSTEMS ................................................................................................................................................................15

INSTRUMENT TABLE ..........................................................................................................................................................16

FOOT CONTROL.....................................................................................................................................................................19

GROUND BOX.........................................................................................................................................................................20

5. HIGH SPEED ASPIRATION ..............................................................................................................................22

6. CHAIR......................................................................................................................................................................23

DOUBLE JOINT HEADREST............................................................................................................................................. 24

HEADREST WITH 3D MOVEMENT................................................................................................................................ 25

ARMRESTS ..............................................................................................................................................................................26

7. SERVICE AND MAINTENANCE.......................................................................................................................27

CLEANING AND DISINFECTION ..................................................................................................................................27

ADJUSTMENTS ....................................................................................................................................................................29

SCHEDULED MAINTENANCE .......................................................................................................................................... 32

EXTRAORDINARY MAINTENANCE............................................................................................................................... 34

8. FORM TO REPORT ACCIDENTS TO PERSONS ...........................................................................................42

WARNING

Before using the equipment, read the O.M.S. instruction manual completely and any instructions supplied

with the accessories.

DUKE EASY S.T.01/3AW Rev.0 01/2017

4

DUKE EASY S.T.01/3AW Rev.0 01/2017

5

1. GENERAL INFORMATION

The instruments table of Duke Easy can accommodate two tools, a syringe and a suction cannula.

The tools are hanging tubes.

Attaching the arm at the base of the dental chair allows a rotation of the table around the patient allowing

use at right and left-handed operators at the same time with a single device.

Ability to install a table tray on a double pantografic arm.

High-speed suction tubes and their connections are easily removable for disinfection treatment. The

filter easily and hygienically clean.

Duke Easy is combinable with the Directive 93/42 Moon dental chair/CE and O.M.S. s manufactured by.

CE 0051 refers only to Duke Easy.

DUKE EASY S.T.01/3AW Rev.0 01/2017

6

SAFETY

Warning symbol

WARNING: Indicates a hazardous situation that can lead to property damage or mild to moderate injury.

DANGER: Indicates a hazardous situation that may result in serious injury or death

Rules

-DANGER: to prevent the risk of electrical shocks, the equipment must be connected exclusively to

power lines provided with a grounding system according to the law in force in your country.

-DANGER: Before powering the equipment after installation, a repair or technical service, check and,

if necessary, hook up the connection of the grounding cables to the screw identified by the grounding

system symbol.

-DANGER: The device must be installed in rooms featuring electrical systems that are up to local code.

-DANGER: The installation of the dental unit has to be done by an OMS authorized technician; the

choice of the pipelines is up to the designer of the electrical system and they have to be placed by a

qualified technician according to the law in force in the country.

-DANGER: Never allow the device to be used by non-professional operators or anybody who has not

read the instruction manual.

-Always check that the device is in good condition.

-WARNING: Do not use the device if any part of it is defective or worn. If this is the case, call in

authorized O.M.S. technical personnel.

-WARNING: Have defective or worn parts replaced with original, warranted O.M.S. spare parts only.

-DANGER: Do not operate the equipment on patients with pacemakers.

-DANGER: Device not suitable for use in rooms where use is made of a flammable anaesthetic mixture

with air or with oxygen or with nitrous oxide.

-WARNING: Do not use the device when there is liquid on the floor.

-WARNING: Tips and dental drills for micromotors, tooth scalers and turbines are not included in

O.M.S. supply. We recommend using parts conforming to the standard ISO 10993 that have to be

cleaned and sterilised according to the methods defined by their manufacturers.

-DANGER: Do not make changes to this device without the manufacturer’s permission. The use of

unapproved accessories and/or unauthorised changes can cause imminent personal injury hazards as

well ad material damages.

-WARNING: All maintenance work must be carried out with the device switched off and with no patient

in the chair.

-DANGER: some parts, identified by the symbol “WARNING – LIVE PARTS”

, are energised with mains voltage even after switching off the power

switch. If these parts require service, cut out voltage to the system supplying power to the equipment,

before making any operations.

-DANGER: the power switch isolates the equipment from the mains electricity. So, before performing

any operations in the equipment, make sure that the power switch is off.

DUKE EASY S.T.01/3AW Rev.0 01/2017

7

-WARNING: For special operations that require chair movements to be locked, make sure to enable

the specific function (see par. LOCKING CHAIR MOVEMENTS).

-WARNING: The instructions found in this manual and in the wiring diagram must be followed to

connect a suction unit; the suction unit must have EC markings as per directive 93/42/EEC as amended

“Medical Equipment” and meet international safety regulations IEC EN 60601-1 (Medical electrical

equipment –General safety regulations), IEC EN 60601-1-2 (Medical electrical equipment –Collateral

standard: Electromagnetic compatibility).

-DANGER: when moving the chair, both in manual and especially in automatic mode, do not place hands

and feet near the bottom of the chair to avoid crushing hazards

-WARNING: during automatic chair movement, the operator must stand near the dental unit.

-WARNING: When moving the instrument table, assistant table and operating lamp, be careful of the

patient and personnel in the surgery to avoid injuring or crushing the patient or personnel in the

surgery.

-WARNING: Never sit on the tip or foot of the chair.

-WARNING: During instrument table movement, patients and personnel in the surgery could be injured

by sharp instrument tips.

-WARNING: before putting equipment into operation after periods of disuse, accurately disinfect the

air and water supply lines, clean and drain the lines and then proceed with disinfection.

-WARNING: In the event of prolonged dental work on senior citizens, be careful of the formation of

bedsores.

-WARNING: When moving the chair and, especially, the head rest, the patient’s hair could become

entangled.

-WARNING: The equipment is equipped with a general water tap. During use, the tap should be open.

At the end of the work day, the tap should be closed or, alternatively, close the unit’s general supply

tap in the surgery.

DEFINITION OF INTENDED USE

Dental unit intended to treat dental pathologies, intended for professional operator use (dentists).

ADMITTED ENVIRONMENTAL CONDITIONS

ADMITTED ENVIRONMENTAL CONDITIONS FOR TRANSPORTATION AND

STORAGE

The packaged device can be exposed for a period of no more than 15 weeks to the following environmental

conditions:

Temperature range -40 to +70°C

Relative humidity range: 10 to 100% non condensing

Atmospheric pressure from 500 to 1060 hPa

DUKE EASY S.T.01/3AW Rev.0 01/2017

8

ADMITTED ENVIRONMENTAL CONDITIONS FOR OPERATION

Temperature range +10 to +40°C

Relative humidity from 30 to 75%

Atmospheric pressure from 800 to 1060 hPa

Nominal operating altitude ≤ 3000m

Pollution degree 2

Overvoltage category II

WARRANTY

The product is covered by a warranty period of 36 (thirty six) months from the date of installation from

the purchaser. The warranty conditions are shown inside the warranty booklet supplied with the device.

The guarantee applies to the purchaser and to the product specified in the installation and testing report

and covers all mechanical and electrical interventions relating to the product concerned.

The guarantee will be valid after the ordering party will be compiled and sent to O.M.S. spa of installation

and testing. Essential condition to access the warranty is return to O.M.S. spa of installation and testing,

in the original by fax or by certified mail within ten days of installation, under penalty of forfeiture of

the guarantee.

O.M.S. SPA Officine Meccaniche Specializzate

Via Dante 20/A 35030 Caselle di Selvazzano (PD) Italia

DUKE EASY S.T.01/3AW Rev.0 01/2017

9

2. TECHNICAL SPECIFICATIONS

Model DUKE EASY

Manufactured by O.M.S. S.p.A. Officine Meccaniche Specializzate

Via Dante 20/A - 35030 Selvazzano Dentro Padova Italia

Class I

Applied parts Type B

Equipment protection level IPX0

Foot control protection level IPX1

ELECTRICITY SUPPLY

Rated voltage 230 Vac +/-10%

Rated frequency 50/60 Hz

Connection to the mains with cables that comply with current code in the given area of use.

Rated current 4A

Rated power 900 W

HYDRO-PNEUMATIC SUPPLIES

Pneumatic supply from 450 kPa to 650 kPa (from 4.5 to 6.5 bar)

(consumption of aspirated air equalling approx. 40 litres/minute)

Water supply from 200 kPa to 400 kPa (from 2 to 4 bar)

(consumption of water equalling approx. 2 litres/minute)

Max. temperature 30 °C

OPERATING PERIODS

Chair intermittent 1' on / 10' off

Syringe 6F (hot water) intermittent 5' on / 10' off

Polymerization lamp intermittent 20’ on / 3’ off

Tooth scaler (with water) intermittent 3' on / 5' off

Micromotor intermittent 3' on / 3' off

Operating lamp continuous

Syringe 3F (cold water) continuous

EDI OPERATING LAMP (with cooling fan)

Halogen lamp: 17 Vac, 95 W

Colour temperature: 5,000 °K

Focal distance:700 mm

Operating field (at 700 mm): 60x180 mm

Max. luminous intensity (at 700 mm): 25000 Lux.

ALYA SPOT LIGHT (led)

Colour temperature: 5,000 °K

Focal distance:700 mm

Operating field (at 700 mm): 170x85 mm

Max. luminous intensity (at 700 mm): 8000-50000 Lux.

Cri (colour rendering index) >85

MAIA SPOT LIGHT (led)

Colour temperature: 5,000 °K

Focal distance:700 mm

Operating field (at 700 mm): 170x85 mm

DUKE EASY S.T.01/3AW Rev.0 01/2017

10

Max. luminous intensity (at 700 mm): 3000-35000 Lux.

GCOMM POLARIS OPERATING LAMP (led)

Colour temperature: 4200-6000 °K

Focal distance:700 mm

Operating field (at 700 mm): 70x140 mm

Luminous intensity: 15000-30000 Lux.

MISCELLANEOUS

Weight circa 165 Kg

Maximum load allowed on chair 135 Kg

Length of foot control cable 2.5 m

Minimum space recommended for device installation approximately 3.20x3.00x3.00 m (LxHxD)

DUKE EASY S.T.01/3AW Rev.0 01/2017

11

IMPORTANT NOTE

The devices, in the models foreseen and indicated in this document, are designed and built in compliance

with directive 93/42/EEC "Medical Devices" (as amended) and international safety standards IEC EN

60601-1 (Medical Electrical Equipment - General Requirements for Safety), IEC EN 60601-1-2 (Medical

Electrical Equipment - Collateral standard: Electromagnetic Compatibility), IEC 80601-2-60 (Medical

electrical equipment: Particular requirements for basic safety and essential performance of dental

equipment), ISO 6875:2011 (dental chairs), ISO 7494-1:2011 (dental units)

, UNI CEI EN ISO 14971:2009 (risk analysis), CEI EN 62304:2006 (ing. Software), CEI EN 62366:2008

(ing. Usability), CEI EN 60601-1-6:2011 (usability).

O.M.S. declines any and all responsibility for equipment safety and reliability in the following cases: if

installation, additions, re-calibration, modifications or changes are not performed by O.M.S. authorised

technicians following the instructions and using the components supplied by O.M.S. exclusively; if the

electric system installed in the workplace does not comply with IEC standards; and/or if the equipment

is not used according to the operating instructions.

NAMEPLATE DATA

An identification plate is affixed to the equipment indicating general device data.

A. Device model

B. Rated voltage and nature of current (alternating )

C. Rated frequency

D. Rated current

E. Rated power

F. Device serial n°

G. Manufacturer

H. Cooling fluid temperature

I. WEEE symbol

J. Applied part Type B

K. Certification markings: Medical device directive 93/42/EEC and subsequent amendments

L. Mandatory, see enclosed documentation

M. Follow operating instructions

3. TECHNICAL INSTRUCTIONS FOR INSTALLATION

PACKAGING

The unit is shipped in a box containing instructions accessory box, S.T. 01/3, lamp *, arm lamp *, * suction,

fixing screws. (*)Present only in case of a specific request at the order.

DUKE EASY S.T.01/3AW Rev.0 01/2017

12

Outside each box there is a flag that indicates the order confirmation numbera and the model.

Note: the packaging of an eventual seat O.M.S. is separated.

ASSEMBLY

1. Remove the equipment from its packaging;

2. Place the chair on the previously made settings using the installation plan and adjust any “play” by

tightening or unscrewing the adjustment feet as necessary, secure the chair to the floor using the

two supplied dowels;

3. If an operating mounting lamp and electrical connection;

4. verify (and possibly perform) ground cables to the screw marked with the ground symbol;

5. to connect the vacuum pump (see the wiring diagram) in the same manner as described in the next

bullet for power cables (securing leads and traction).

6. remove the cover at the base of the dental chair, unscrewing the screws D

to maintain water and air connections (see section

developed), aspiration, exhaust and finally the power grid (Terminal); the power cables on the terminal

board must be general, with nylon ties, insulating specially drilled and placed under the Terminal, in

particular it must be ensured that, in the event of failure of the fasteners (clamps), the protective

conductor is not subject to traction as long as network cables are still connected to terminal

3. Fit the accessories (instruments), if any, on the instrument and dental assistant tables.

N.B.: Refer to the wiring and installation diagrams provided for all electrical connections.

DUKE EASY S.T.01/3AW Rev.0 01/2017

13

CONNECTIONS

First, make sure that the flow of air and water from the water and pneumatic mains is regular. O.M.S.

declines any and all responsibility for faults or damage originating from non-compliance with the warning

below:

Water supply:

Water with medium/low salt content (fit a water softening device if necessary), to be connected to the

6x8 diameter tube (see paragraph TECHNICAL SPECIFICATIONS for admitted pressure).

Pneumatic supply:

Compressed air, preferably dehumidified and oil-suspension free, to be connected to the 4x6 diameter

tube (see paragraph TECHNICAL SPECIFICATIONS for admitted pressure).

We recommend making a temporary direct connection between the water delivery pipe and the drain pipe,

and letting the water circulate for a few seconds before installing the equipment. This enables elimination

of any impurities from the tubes.

TESTING AND PUTTING INTO OPERATION

IMPORTANT WARNING

During testing, check the mechanical stability of the equipment after placing all the mobile elements and

accessories (table, lamp, etc.) in the most unsuitable position possible.

1. Ensure that the instrument table is perfectly level: if an unusual tilting is identified, adjust the table

using the screw (detail A in Figure) located inside the front part of the arm.

2. Check the manual pantograph base and backrest up and down controls, and the automatic return to

exit, rinse position and return to last position control to ensure they are working properly. Check and

store correct positioning of the programs (see sections MANUAL CONTROLS and AUTOMATIC

CONTROLS).

3. Check that limit switches and safety systems are working properly (see section SAFETY SYSTEMS).

4. Check correct calibration of the pressure regulators and general flow regulators and that of each

instrument. These devices have already been calibrated by O.M.S. in the workshop, but they may

require an inspection or re-calibration.

DUKE EASY S.T.01/3AW Rev.0 01/2017

14

Note: The equipment is equipped with a general water tap. During use, the tap should be open. At the

end of the work day, the tap should be closed or, alternatively, close the unit’s general supply tap in the

surgery.

DANGER: Before performing any operations in the equipment, always make sure that the power switch is

off..

DUKE EASY S.T.01/3AW Rev.0 01/2017

15

4. CONTROLS - ADJUSTMENTS - INDICATORS

SAFETY SYSTEMS

The dental chair is supplied with safety devices which minimise the risk of crushing or collision with

underlying objects during chair descent. Safety devices include a special sensor on the dental chair back

and an electromechanical safety device installed at the base of the dental chair back.

Whenever the sensor installed on the dental chair back is engaged during a descent movement (either of

the pantographic arm or chair back), the part moving down stops. A warning LED at the bottom of the

seat (detail B) goes ON and stays ON until the obstacle causing safety device engagement is cleared. To

perform the required movement, remove the obstacle and repeat the control.

The sensor installed on the back of the dental chair is calibrated as instructed below.

-Place the chair in the permanent position;

-Put a screwdriver in the hole for the calibration of the sensor located at the bottom of the chair seat

(detail B). Turn the screwdriver clockwise to reduce the sensor sensitivity and anticlockwise to

increase it.

-Control the pantographic arm or chair back to move downwards and touch the back of the dental chair

to engage the safety sensor (detail A) in order to check its sensitivity. Repeat the operations from

the previous item until the ideal sensor sensitivity is found.

When the back safety sensor is engaged, all downward movements of both the back and pantographic arm

are disabled.

The back of the dental chair is also provided with an electric and mechanical safety device which stops

the descent movements of both the pantographic arm and back whenever obstacles are present in the

outreach of the keyboard. Whenever this safety device is engaged, all downward movements of both the

pantographic arm and back are disabled.

During automatic movements of the dental chair (position reset, memorised positions or rinsing positions),

press any control of the dental chair (on the pushbutton panels of the dental unit or foot control) to

immediately stop the dental chair.

Dental chair movement may be disabled both at equipment switch on and during normal operation, if one

or more than one safety system is active.

DUKE EASY S.T.01/3AW Rev.0 01/2017

16

INSTRUMENT TABLE

The instrument table offers two tools, a syringe and a suction cannula.

Comprises the Group of solenoid instruments with clearly visible, all its adjusters. The functions of each

device are described in the chapters to the forms tool. Regulations that are not equipped with knob must

be takend off by authorised technicians O.M. S

PULSANTIERA

The controls are entirely under sealed membrane, this enables greater reliability, eliminating crevices

and the disinfection of the surface.

The key functions are:

Reversing command of the micromotor with warning led

(with led off the direction of rotation is normal)

command of spray preselection and fiber optics

(press button for 3 seconds), with preselected led fibre optic lighting

and with preselected spray active led.

The other buttons are inactive.

TURBINE MODULE

Turbine operation is achieved by lifting the instrument from its position, moving it to the surgical field,

and then press the foot pedal (see operation section).

Lifting the instrument by the table are inhibited all other dynamic tools and all the movements of the

dental chair.

DUKE EASY S.T.01/3AW Rev.0 01/2017

17

The spray is always preselected. To adjust the water to spray one acts on the faucet in place behind the

Chair. By turning the tap clockwise you get a gradual decrease of water flow to the spray until its complete

exclusion, the opposite rotating in the opposite direction. It is recommended not to intervene in other

regulations placed at the side of the spray faucet.

If the instrument is equipped with optical fibres lighting system, these are switched on by pressing the

control command pad spot Tablet (when the function is on, it affects all instruments). The

activation of the function is displayed by the lit led (D).

Air pressure Recommended (measured during operation of the turbine) is set at the time of testing in

the O.M.S.. Calibration must be re-evaluated at the time of installation of the appliance using a

manometer, respecting the pressure values indicated by the manufacturer of the turbine. This must be

done by an authorised O.M.S..

For more details see the attached manufacturer's instructions.

ELECTRIC MICROMOTOR MODULE

The function of the micromotor is achieved by lifting the instrument from its place, moving it to the

surgical field and then pressing the foot pedal (see operation section MICROMOTOR).

Lifting the instrument from the table are inhibited all other dynamic tools and all the movements of the

dental chair.

The micromotor allows you to work with a variable speed from a minimum of about 900 RPM to a maximum

of 40,000 rpm

Normally the micromotor will have a clockwise direction rotation. For reversal of direction of rotation,

after lifting the tool, activate the reverse command in the instruments table.

It is recommended that the change of direction of rotation is made only when the motor is stopped, to

prevent damage.

The spray is preset by typing the command ; the activation of the function by the lit led is

displayed. See also section OPERATION micromotor.

To adjust the water to spray one acts on the faucet in place behind the Chair. By turning the tap clockwise

you get a gradual decrease of water flow to the spray until its complete exclusion, the opposite rotating

in the opposite direction. It is recommended not to intervene in other regulations placed at the side of

the spray faucet.

DUKE EASY S.T.01/3AW Rev.0 01/2017

18

If the instrument is equipped with optical fibres lighting system, these are switched on by pressing

The command , place on command pad table (when the function is on, it affects all instruments).

The activation of the function is displayed by the lit led (D).

SCALER MODULE

Generator operation is achieved by lifting the instrument from its place, moving it to the surgical field

and then pressing the foot controller lever (see operation section GENERATOR).

Lifting the instrument by the table are inhibited all other dynamic tools and all the movements of the

dental chair.

To adjust the water to spray one acts on the faucet in place behind the dental chair. By turning the tap

clockwise you get a gradual decrease of water flow to the spray until its complete exclusion, the opposite

rotating in the opposite direction. It is recommended not to intervene in other regulations placed at the

side of the spray faucet.

If the instrument is equipped with optical fibres lighting system, these are switched on by pressing

the command , placed on the command pad of the table (when the function is on, it affects all

instruments). The activation of the function is displayed by the lit led (D).

For more details see the attached manufacturer's instructions.

For the scaler SATELEC NEWTRON SP power regulation must be done according to the tip on the

handpiece.

SYRINGE MODULE

The syringe operates at any time by simply pressing one of the two levers enabling either water or air

supply (left-hand lever for water and right-hand lever for air). When these two supply buttons are

pressed simultaneously, spray water is delivered.

For further details refer to the manufacturer’s operating instructions enclosed.

DUKE EASY S.T.01/3AW Rev.0 01/2017

19

FOOT CONTROL

The equipment foot control was designed to control all the possible functions of the instruments with a

simple movement of the lever (A).

N.B.: when the instrument is extracted, it is automatically connected to the foot control, thus disabling

all the other instruments even at a subsequent extraction (by the dental assistant, for instance).

TURBINE OPERATIONS

Extract the instrument from its housing (this operation is shown on the display). Then:

- pressing the lever (A) of the foot control in the rest position will enable the chip-blower;

- move the lever A to the right to operate the instrument. If lever A is pressed simultaneously, the

turbine is sprayed (standard configuration). Upon request, at the time of installation, the technician can

change the connections so that the spray function can be operated without having to press the lever.

MICROMOTOR OPERATIONS

Extract the instrument from its housing (this operation is shown on the display). Then:

- pressing the lever (A) of the foot control in the rest position will enable the chip-blower;

- move the lever A to the right to operate the instrument. The spray is pre-selected in the instrument

table by engaging the control ; Then, spray delivery is possible when the foot control lever (A) is

slightly pressed with the instrument in operation (standard configuration). Upon request, at the time of

installation, the technician can change the connections so that the spray function can be operated without

having to press the lever.

To invert the micromotor rotation, move the foot control lever A to the left and press it downwards. This

operation is viewed on the display, and an on-off beep accompanies this function, which is disengaged by

moving the lever (A) to the left again and pressing it downwards.

SCALER OPERATIONS

DUKE EASY S.T.01/3AW Rev.0 01/2017

20

After removing the instrument from its place by moving the lever (A) to the right to activate the tool.

The spray you pre-select in instruments table by typing the command ;then you can have the

spray dispensing by pressing the lever rheostat (A) if the instrument is in function (standard

configuration). Upon request, at the time of installation, the technician can change the connections so

that the spray designed to be dispensed without the need to depress the lever.

CHAIR CONTROLS FROM THE FOOT CONTROL

The foot control is equipped with two side levers (see det. B and C) that are operated to position the

dental chair using foot controls:

-moving the lever (B) up will raise the seat;

-moving the lever (B) down will lower the seat;

-moving the lever (C) up will lower the backrest;

-moving the lever (C) down will raise the backrest.

OTHER ACCESSORIES

For accessories not previously described buy indicated in the product description, see the specific user

manuals supplied with the equipment.

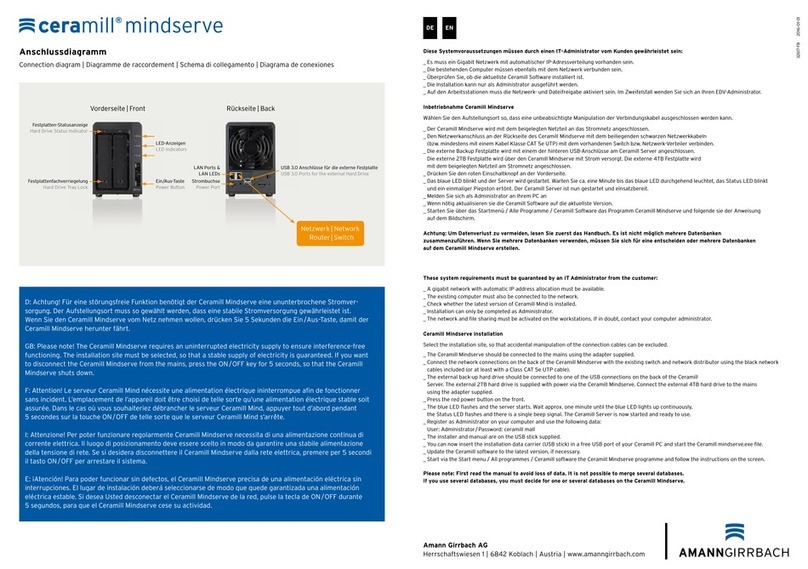

GROUND BOX

In the box to the floor are housed all electrical control systems, pneumatic and water together.

Inside, it is possible to carry out the connection of the appliance to the mains, the mains water supply,

drainage, compressed air and the flue pipe from the engine of the surgical suction, if any.

Access is by unscrewing the screws D and remove plastic cover C with the caveat of disconnect power

before opening (as described in the section on SAFETY).

Table of contents

Other OMS Dental Equipment manuals

Popular Dental Equipment manuals by other brands

NSK

NSK S-Max M65 Operation manual

Aseptico

Aseptico ALU-40TC Operation and maintenance instruction manual

dentalfarm

dentalfarm MICRA Evoluzione User and maintenance manual

DENTSPLY

DENTSPLY thermaprep 2 Directions for use

Zhermack

Zhermack hurrimix 2 user manual

Dabi Atlante

Dabi Atlante Bellagio owner's manual