1 Introduction

1-1Eagle Operator Manual - OPEX Corp. Use Only - Not for Distribution

System Overview

The Eagle High-Speed Mail Extractor pushes the envelope of mail and remittance

processing to even greater limits. Combining the best in mail qualifying, opening and

extracting with all the decisioning time necessary to facilitate the quickest deposit

ready processing in the industry, the Eagle blurs the line between the mailroom and

payment processing. By optimizing functionality, the Eagle collapses workflows and

reduces handling to greatly increase productivity.

In one continuous operation, the Eagle sorts, opens, extracts, images, orients and

outputs finished work. With five-hundred milliseconds of decisioning time, the Eagle

also allows for inputs from multiple plug-in applications to assure that the

processing decisions being made are the most accurate in the industry. Once the

sort decision has been made, the checks and documents are routed to the

appropriate output bin to assure optimal downstream processing as necessary. In

short, the Eagle represents the most innovative mail opening and payment

processing technology in the industry, collapsing the workflow and relegating multi-

touch processing a thing of the past in the Accounts Receivable Conversion and

Check 21 world.

Features of the Eagle include:

• Check 21/ARC compliance Allows for most efficient clearing method to be utilized

while assuring compliance with applicable rules and regulations. The Eagle allows

you to interface with the image quality check software of your choice and easily

integrates the software into the workflow via the IEM (Image Export Module) func-

tionality.

•BufferfeederCompensates for envelopes that are fed but do not meet the criteria

for processing on the machine. As these envelopes are outsorted, the buffer feeder

fills in what otherwise would have been a gap, maximizing throughput. The buffer

feeder is capable of negating the throughput impact of up to 15% outsorts on

average.

• Refeeder The Eagle refeeder allows for pre-extracted stubs and checks to be

processed in the same manner as those still in the envelopes.

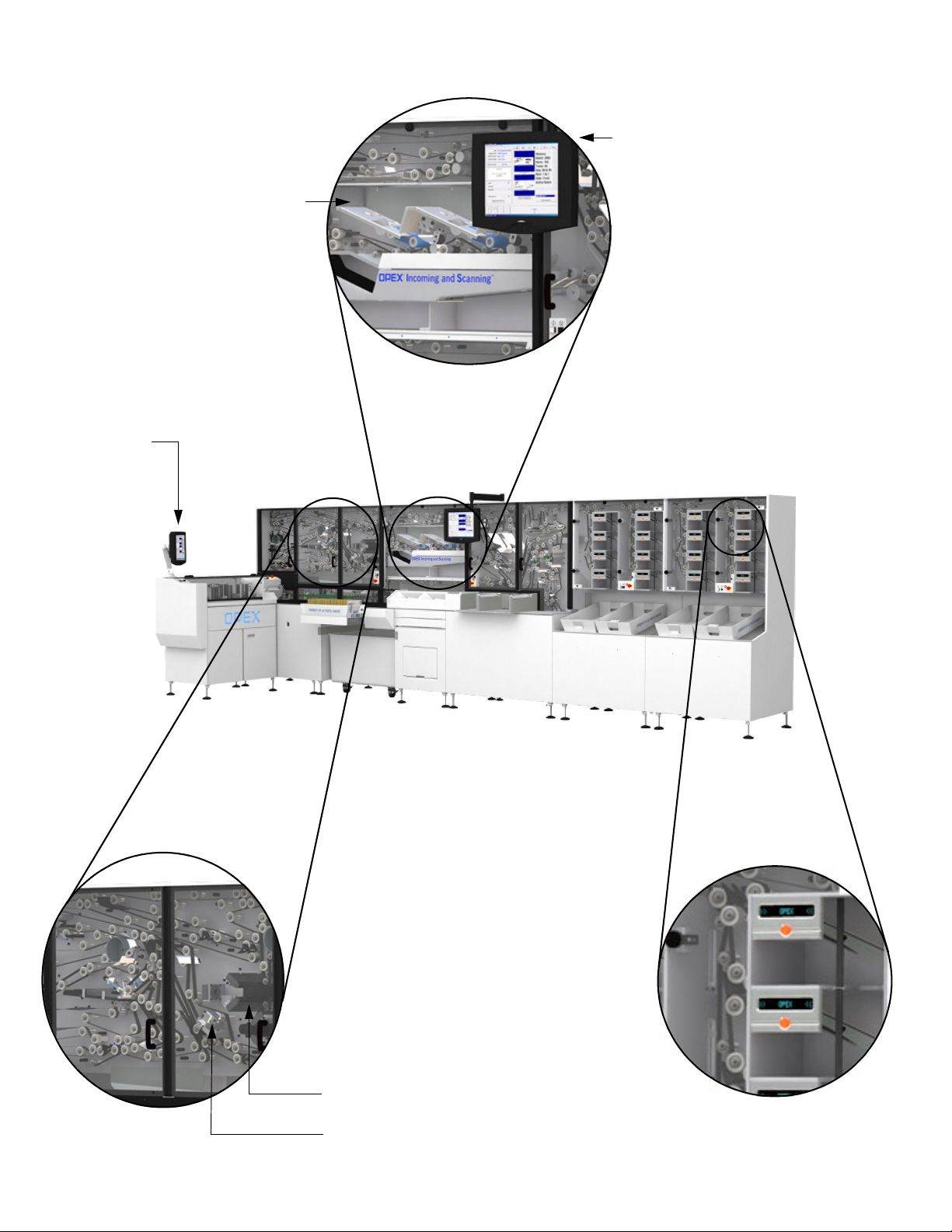

• Operator cockpit Central to the machine, the operator cockpit strategically

locates many of the operator functions within easy reach. This allows for quicker

operator response time and allows the operator to observe the entire machine

while working from the cockpit.

• Touch-screen controls Eliminates the immediate need for the keypad because of

its convenient accessibility.

• Automatic Jam Control Greatly reduces downtime by electronically monitoring

the paper path, notifying the operator of the location of jams and allowing for run

resumption from buttons conveniently located at various positions on the

machine.

• Image Export Provides image capture of checks and documents for immediate

pass-off via a network connection. Five-hundred milliseconds of decisioning time

allows for input from multiple plug-ins.