(15.09.23) OW_DVR_BA_855060202_00_EN Orbitalum Tools GmbH, D-78224 Singen, www.orbitalum.com, Phone +49 (0) 77 31 792-0 3

DVR | Operating instructions

1. About these instructionsAbout these instructions............................................................................55

1.1 Warning messages......................................5

1.2 Further symbols and displays...................5

1.3 Abbreviations...............................................5

1.4 Further applicable documents .................5

2. Owner information and safety instructions......6

2.1 Requirements for the owner.....................6

2.2 Using the machine ......................................6

2.2.1 Intended use .....................................6

2.2.2 Machine constraints........................7

2.3 Environmental protection and disposal .7

2.3.1 Cooling liquid ....................................7

2.3.2 Electric tools and accessories .....8

2.4 Personnel qualification..............................8

2.5 Fundamental information on operational

safety.............................................................8

2.6 Personal protective equipment ...............9

2.7 Remaining risks...........................................9

2.7.1 Injury through high weight.............9

2.7.2 Prick injury through pointed elec-

trode ...................................................9

2.7.3 Danger of crushing through rotat-

ing turntable and chuck..................9

2.7.4 Danger of crushing through being

caught in by moving parts ........... 10

2.7.5 Danger of cuts at sharp edges.... 10

2.7.6 Burns and danger of fire through

high temperatures ......................... 10

2.7.7 Tripping over the hose package

and lines........................................... 10

2.7.8 Electric shock .................................. 11

2.7.9 Damage to eyes through radiation

............................................................ 11

2.7.10 Dangers through electromagnetic

fields .................................................. 11

2.7.11 Dangers through faulty mounting11

2.7.12 Danger through loose or danger-

ous structures ................................. 11

2.7.13 Risk of suffocation through an

excessive argon share in the air . 12

2.7.14 General injuries through tools .... 12

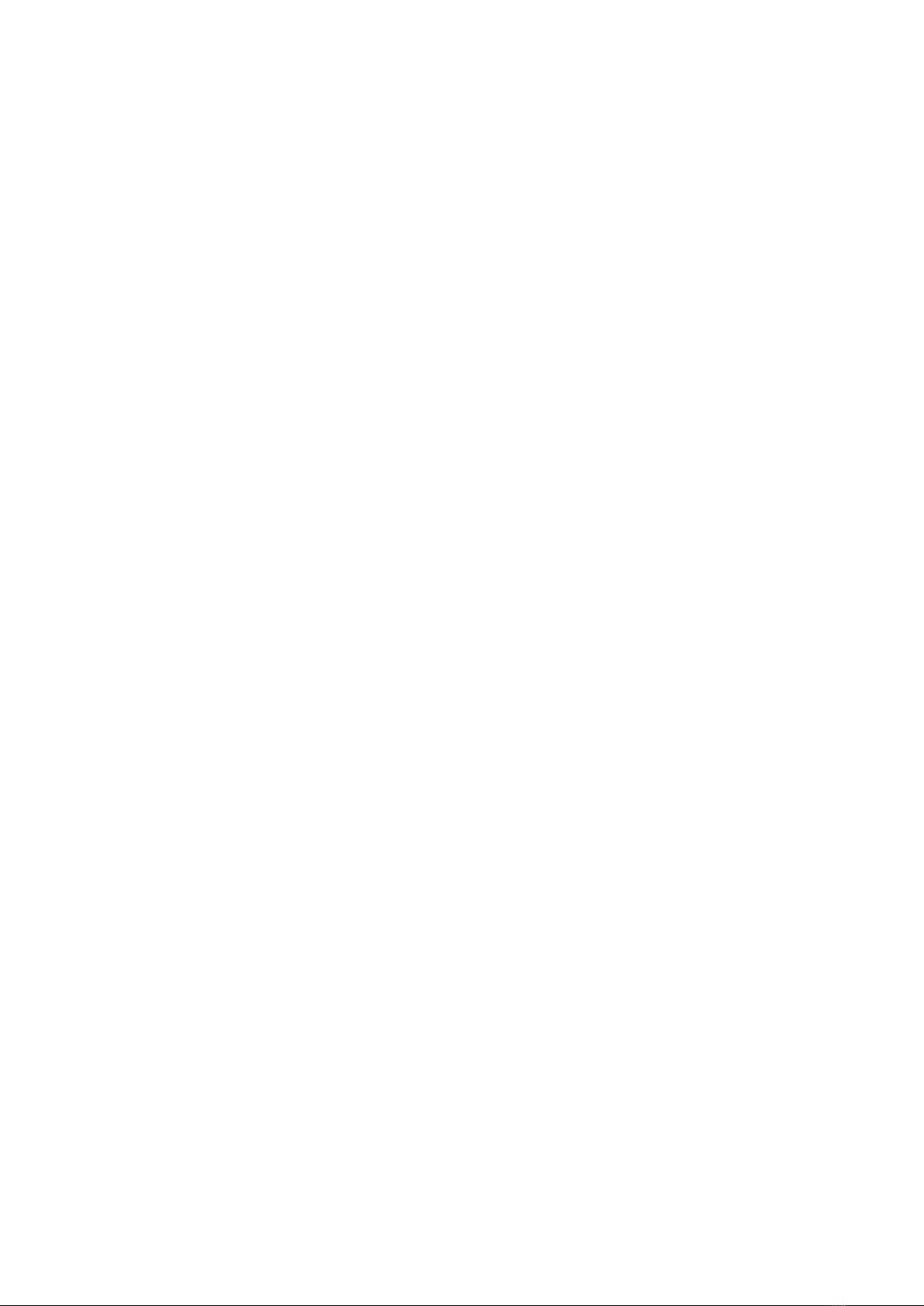

3. Description ............................................................ 13

3.1 Warning signs............................................. 14

4. Scope of application ............................................ 15

4.1 Clamping range three-jaw lathe chuck

(optionally).................................................. 15

5. Technical specifications...................................... 16

6. Storage and transport......................................... 18

6.1 Gross weights ............................................ 18

6.2 Transporting the welding turntable ...... 18

6.3 Preparing storage..................................... 18

7. Commissioning...................................................... 19

7.1 Scope of delivery ...................................... 19

7.2 Checking the scope of delivery .............. 19

7.3 Accessories (optionally available) ......... 19

7.4 Setting up ................................................... 19

7.5 Clamping chuck swivel range setting ... 21

7.6 Preparing initial operation ...................... 21

8. Set-up and mounting ......................................... 22

8.1 Procedure .................................................. 22

8.2 Connect the control cable...................... 22

8.3 Connect the ground cable ..................... 22

8.4 Connecting the welding power supply. 23

8.4.1 DVR connection scheme.............. 24

8.5 Torch arm position setting..................... 26

8.6 Torch arm position setting .................... 27

8.7 Torch fine setting .................................... 28

8.8 Setting up the torch ................................ 28

8.9 Carry out the gas and cooling-liquid

function test.............................................. 29

8.10 Calibrate the welding turntable ............ 29

8.11 Configure the welding procedure ......... 29

9. REMOTE CONTROL (optionally available)...... 30

9.1 Operating elements................................. 30

9.2 Welding........................................................ 31

9.3 Aborting welding....................................... 31

10. Servicing and maintenance............................... 32

10.1 Instructions for care................................ 32

10.2 Maintenance and care............................. 32

10.2.1 Corrosion protection .................... 32

10.2.2 Lubrication.................................. 32

10.2.3 Lubrication of the track ........... 32

10.2.4 Lubrication intervals................. 33

10.2.5 Standard cleaning process of the

weld turntable................................ 33

10.3 Servicing/Customer service.................. 34

TABLE OF CONTENTS