(12.03.18) OW_HX 16P_BA_848060202_01_EN orbitalum tools GmbH, D-78224 Singen, www.orbitalum.com, Tel. +49 (0) 77 31 792-0 3

HX 16P | Operating instructions

1. About these instructions .................................................................................................................................. 4

1.1 Warning messages................................................................................................................................. 4

1.2 Further symbols and displays................................................................................................................. 4

1.3 Abbreviations ........................................................................................................................................ 4

2. General information ......................................................................................................................................... 5

2.1 Technical specifications ......................................................................................................................... 5

3. Description ...................................................................................................................................................... 6

3.1 Machine body ........................................................................................................................................ 6

3.2 Pneumatic clamping system ................................................................................................................... 6

3.3 Connections........................................................................................................................................... 6

4. Use and maintenance....................................................................................................................................... 7

4.1 General information ............................................................................................................................... 7

4.2 Positioning of the weld head................................................................................................................... 7

4.3 Starting of the orbital weld head ............................................................................................................ 7

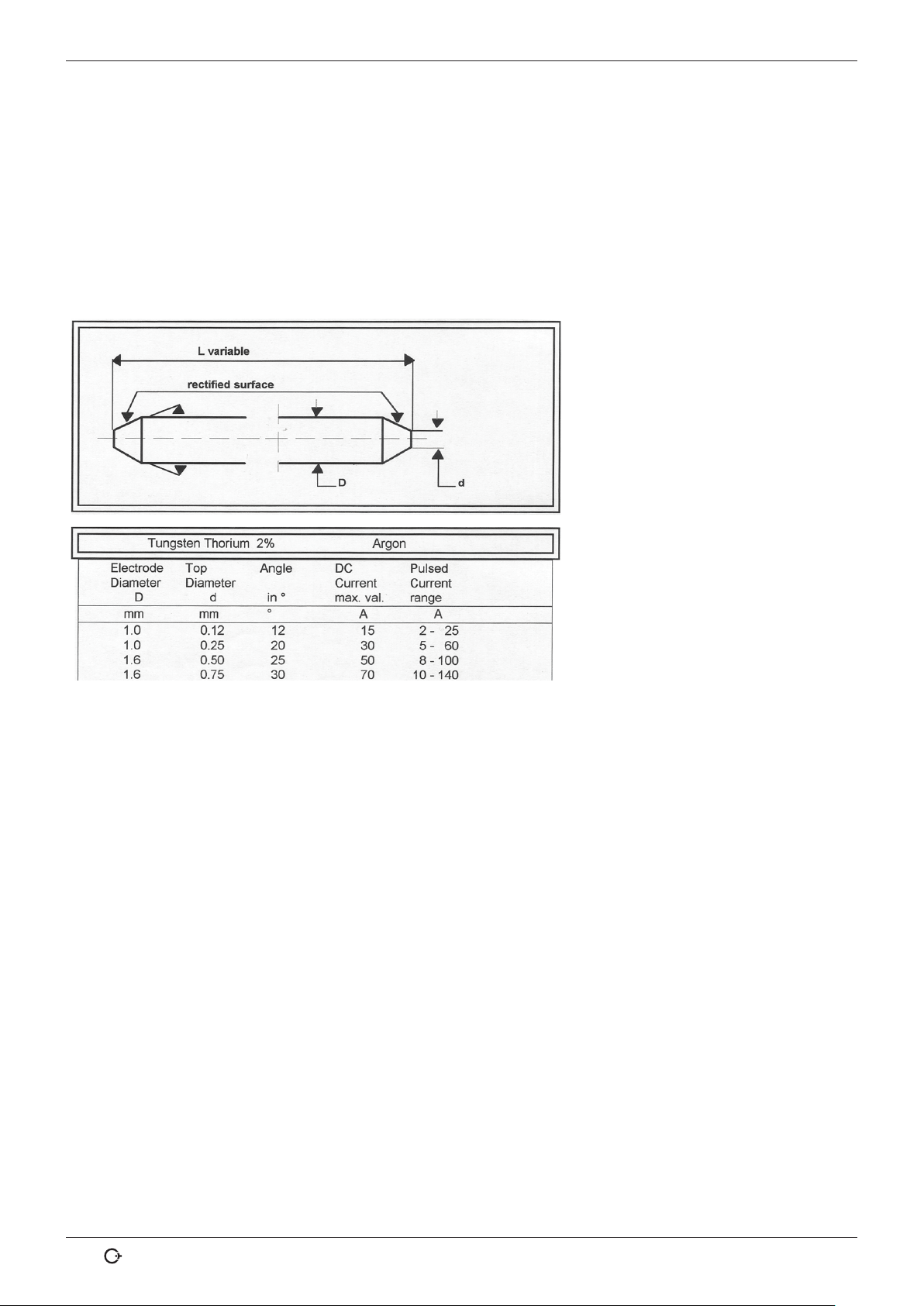

4.4 Preparation and replacement of the electrode......................................................................................... 8

4.5 Adjustment and replacement of microswitch........................................................................................... 8

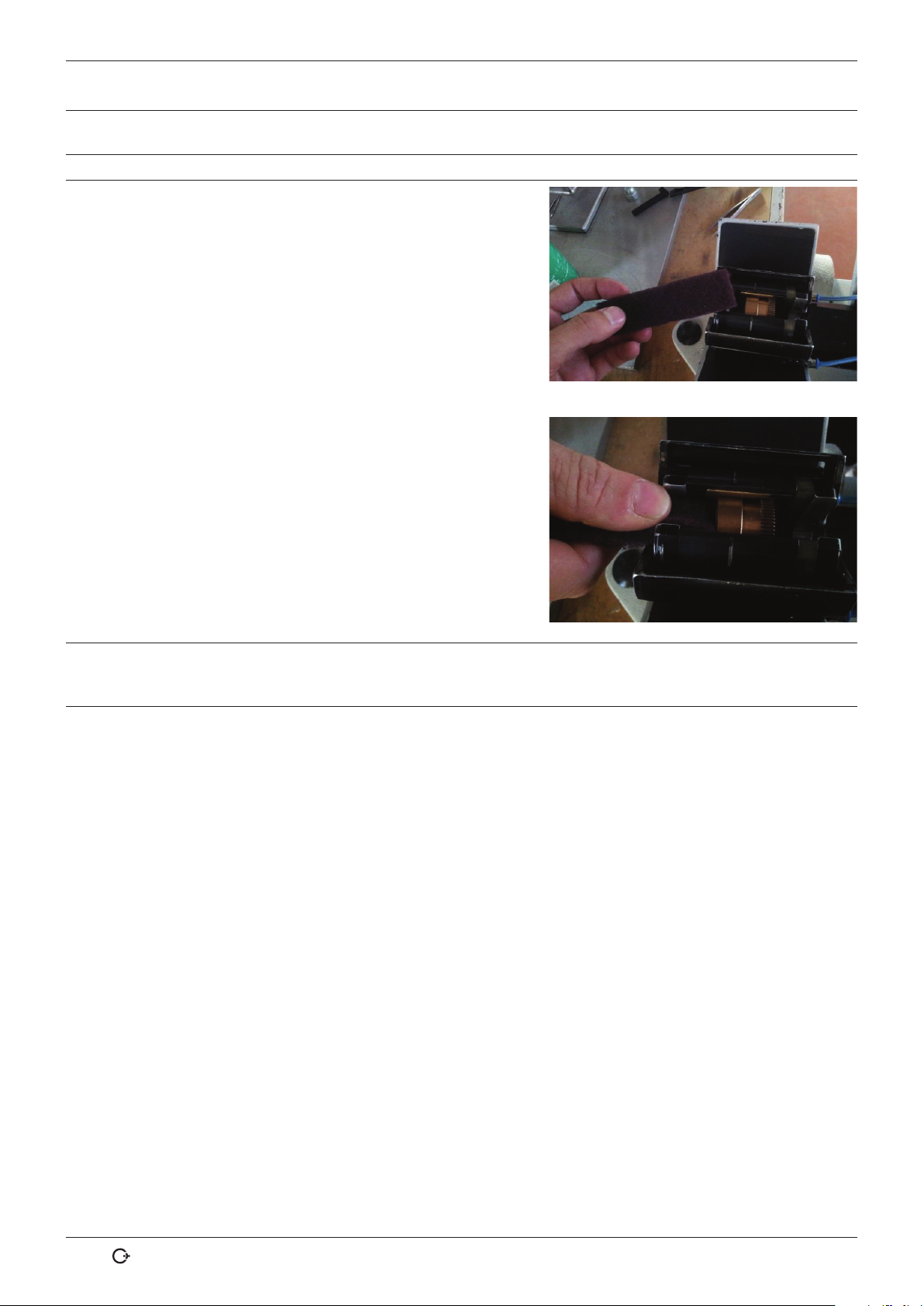

4.6 Cleaning the orbital weld head ............................................................................................................... 9

4.6.1 Equipment ................................................................................................................................... 9

4.6.2 Procedure .................................................................................................................................... 9

5. General safety rules ........................................................................................................................................11

5.1 Welding cables......................................................................................................................................11

5.2 Polarity switch......................................................................................................................................11

5.3 Ground power circuit .............................................................................................................................11

5.4 Welding operations ...............................................................................................................................12

5.5 Explosion hazards.................................................................................................................................12

5.6 Ventilation ............................................................................................................................................12

5.7 Solvents ...............................................................................................................................................12

5.8 Fire hazards..........................................................................................................................................13

5.9 Dangers of electric shock ......................................................................................................................13

5.10 Face protection .....................................................................................................................................13

5.11 Eye protection.......................................................................................................................................13

5.12 Clothing................................................................................................................................................14

5.13 Hot metals burns ..................................................................................................................................14

TABLE OF CONTENTS