IM0973570 A 05

12

Installation manual

Image processing: Color and gamma correction, 3D noise correction, edge

enhancement, digital WDR, advanced contrast enhancement, auto white-balance,

auto exposure control, mirroring, flipping, photometric and geometric lens

distortion correction.

Electrical

Power input: 12/24V/DC. Below 7V: camera is non-functional. Above 33V the

overvoltage protection is activated. This overvoltage protection is deactivated

below 30V. Powercircuit is protected up to 80V/DC. Outputs are Short Circuit

Protected.

In all these above mentioned values; a tolerance of +/-10% is applied.

Power consumption: <2W.

Transient protection: Camera may be powered directly from 12V or 24V battery

without additional electrical protection since camera has an integrated circuit

that protects the camera against over- and undervoltage, spikes, ripples and

loaddumps.

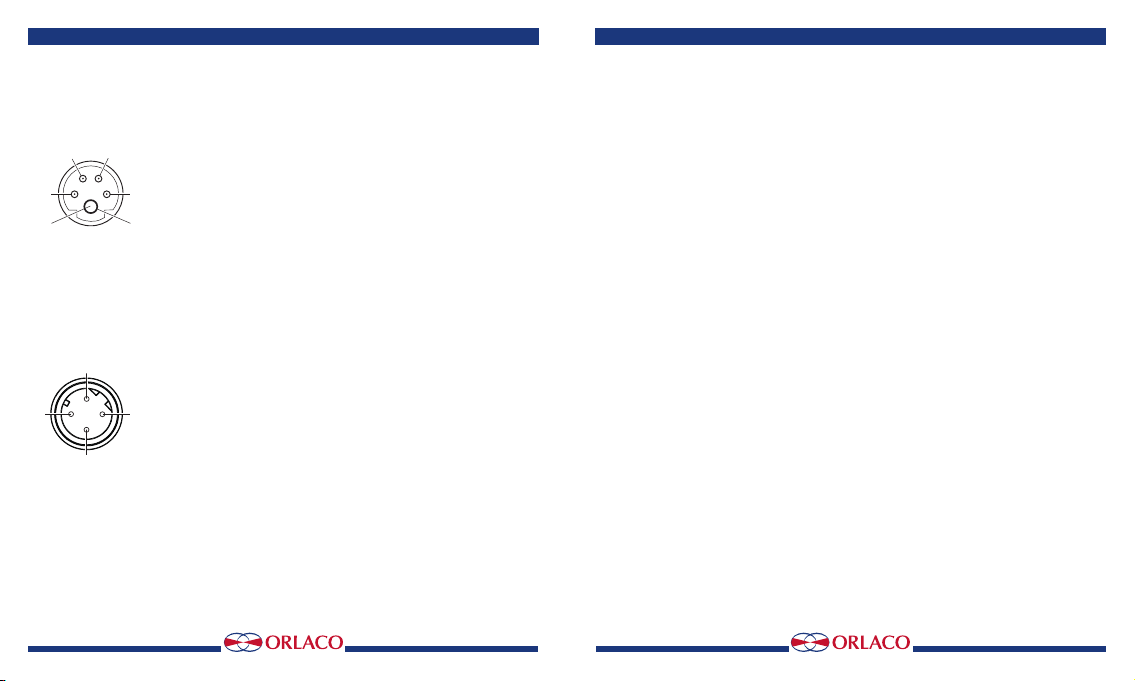

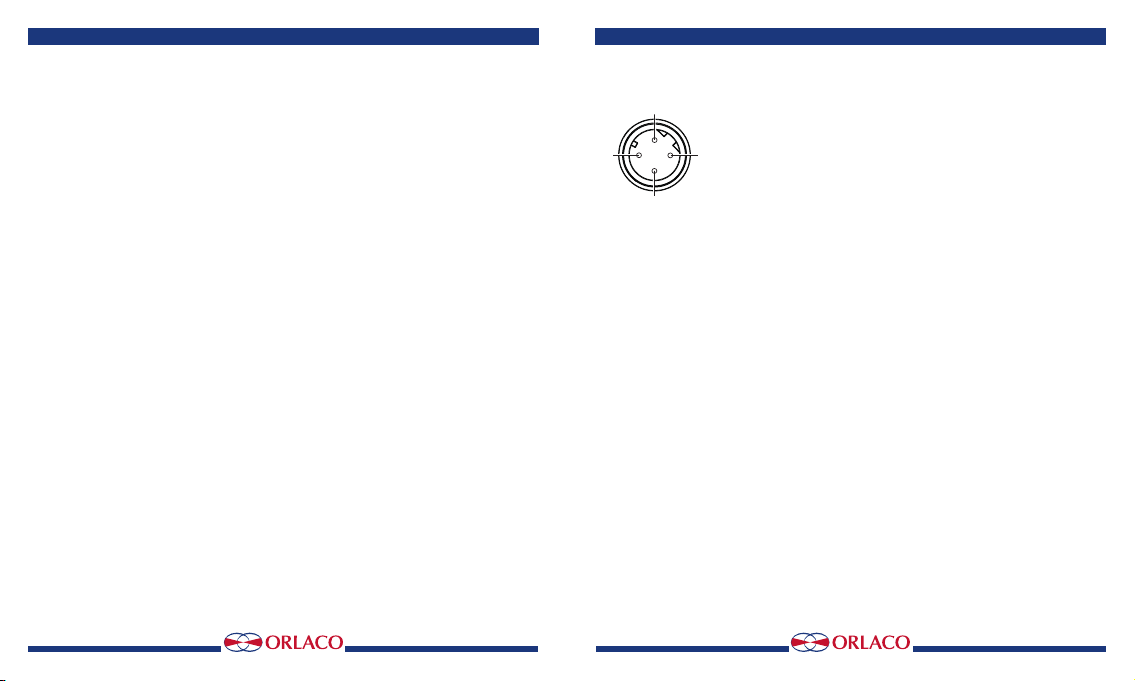

Connector/Cable: 6 wire: 2x twisted pair for data and 2 wires for power supply.

Connector 4-pin M12 d-coded for data and open wires for

power supply.

Min. cable bend radius: 50mm.

Mechanical

Housing: Anodised aluminium, black, UV resistant, light fastness >8, corrosion

proof according IEC 60068-2-52 salt mist, cyclic.

Filling: Camera is potted with automotive potting resin

Ingress protection: IP67 according to IEC 60529; dust tight and protected

against the effects of continuous immersion in water up to 1m under water for

30 minutes, IP69k according to DIN 40050-9: camera can withstand a high

pressure cleaning/washing with water: 14-16L/min. 80°C and 100 bars flow.

9

Installation manual

Electrical

Power input:Camera HMOS may only be powered by Orlaco monitor HLED. The

camera HMOS has no internal power protection.

Power consumption: <2W

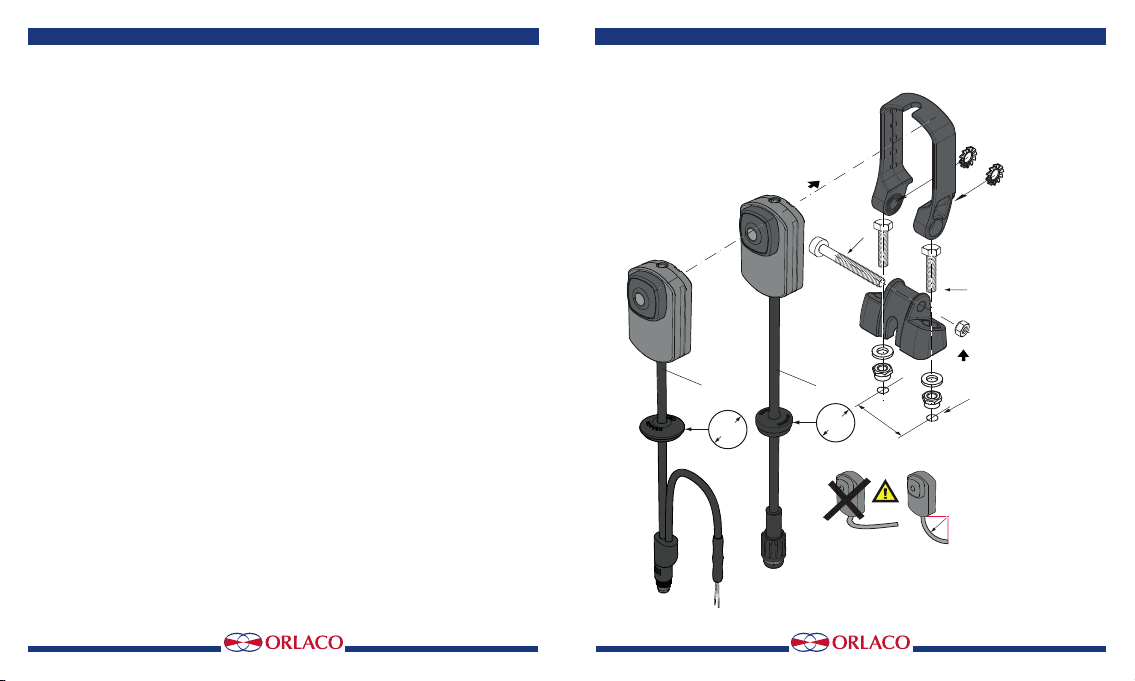

Connector/Cable: 0,5m cable with Coax and molded male connector (camera

power input and video output).

Min. cable bend radius: 50mm.

Mechanical

Housing: Anodised aluminium, black, UV resistant, light fastness >8, corrosion

proof according IEC 60068-2-52 salt mist, cyclic.

Filling: Camera is potted with automotive potting resin

Ingress protection: IP67 according to IEC 60529; dust tight and protected

against the effects of continuous immersion in water up to 1m under water for

30 minutes. IP69k according to DIN 40050-9: camera can withstand a high pres-

sure cleaning with water: 14-16L/min. 80°C and 100 bars flow.

Mounting hardware: Standard stainless steel.

Shock constancy: Shock and vibration resistant for usage on trucks, cranes,

fork-lifts, maritime applications, machinery.

Camera bracket: glass reinforced polyamide, test: 50 Nm at -40°C to +85°C.

Weight: 0,24kg. including cable, bracket and mounting material. 0,30kg. in

standard packing.

Truck use: Withstand all fluids and materials used in and around trucks like:

ammonia solution 5%, ethanol 80-100%, isopropanol 5-10%, soapy water (min.

50% soap per volume), alkaline degreasing compounds(used in high pressure

washing equipment).