IM0973510 R1-2

2

Before you start using this equipment, please read this manual carefully and

follow all instructions. We recommend that you keep this manual in a safe place

for reference purposes.

If you have any questions or issues concerning the operation of this equipment,

consult the relevant section in the manual or contact the Orlaco Products BV

Service department.

The camera/display systems from Orlaco comply with the latest CE, ADR, EMC

and mirror-directive regulations. All products are manufactured in accordance

with the ISO 9001 quality management, ISO/TS16949 quality automotive and

ISO 14001 environmental management.

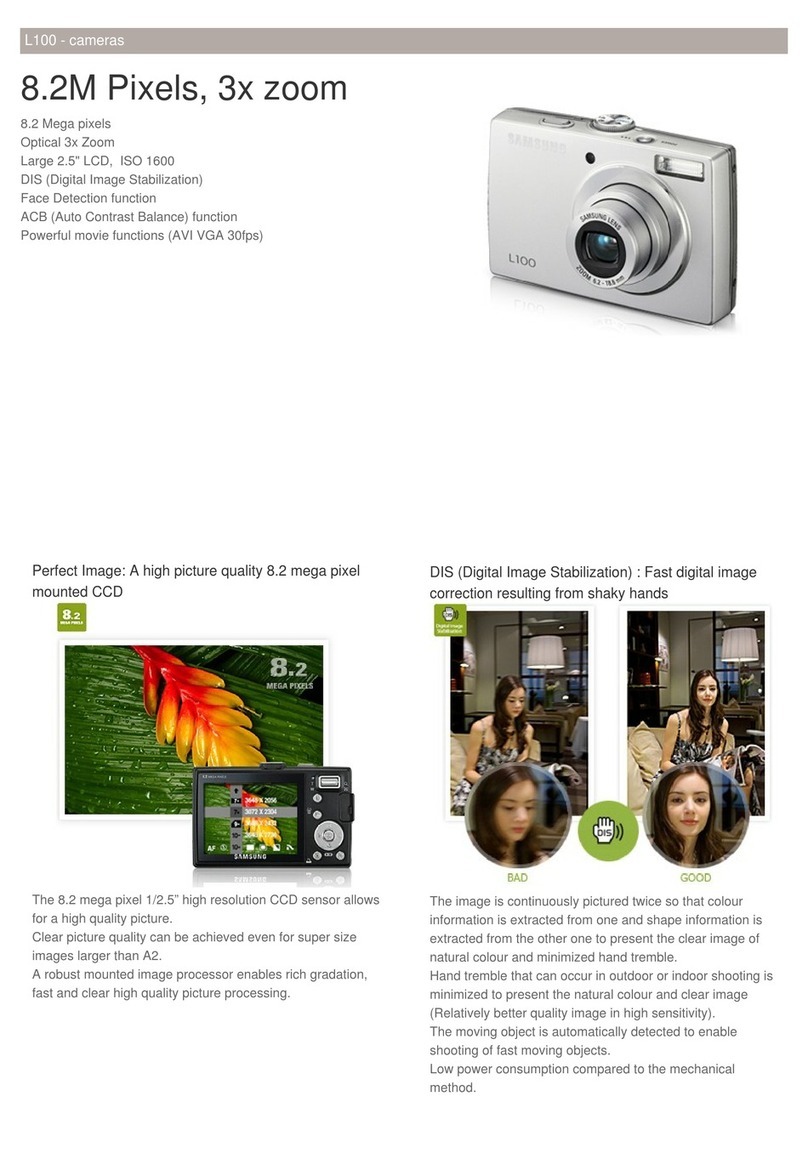

Compact Camera

Type FAMOS PAL NTSC

Safety

In order to guarantee safe operation, these safety instructions must

be read before you start using this equipment.

• Do not open the enclosure. This can cause damage, short-circuiting or

electrical shocks.

• Do not expose the equipment to extreme temperatures. This can cause defor-

mation of the enclosure or damage to internal components.

• Repairs may only be undertaken by the manufacturer.

• The equipment must be assembled as shown in this manual.

Installation manual

11

Installation manual

5. Disposal

Disassembly, removal and disposal. Local regulations for dealing with waste

must be followed when disposing of disassembled components or entire units.

6. General terms and conditions

Orlaco Products BV is not liable for damage resulting from inadequate servicing,

incorrect usage or alterations made to the equipment without informing the

manufacturer in writing.

This installation manual has been made available by Orlaco Products BV.

All rights reserved. No part of this manual may be reproduced and/or made

public in printed form, in photocopy form or on microfilm, or in any other way,

without the prior written permission of Orlaco. This also applies to the associa-

ted drawings and figures.

Orlaco reserves the right to make changes to components at any time without

informing customers beforehand or directly. All dimensions given are for com-

mercial purposes.

For information regarding repairs that is not covered in this manual, please

contact the Orlaco Products BV service department.

This manual has been prepared with all due care and attention. However, Orlaco

Products BV cannot be held responsible for any errors in this manual or any

consequences thereof.

7. Revision details

R1-0. First issue, January 2015.

R1-1. Specifications changed, page 8, February 2015.

R1-2. Camera lenses(page 8) and Friction pad added(page 4), October 2015.