2. Purpose 2

3. General 2

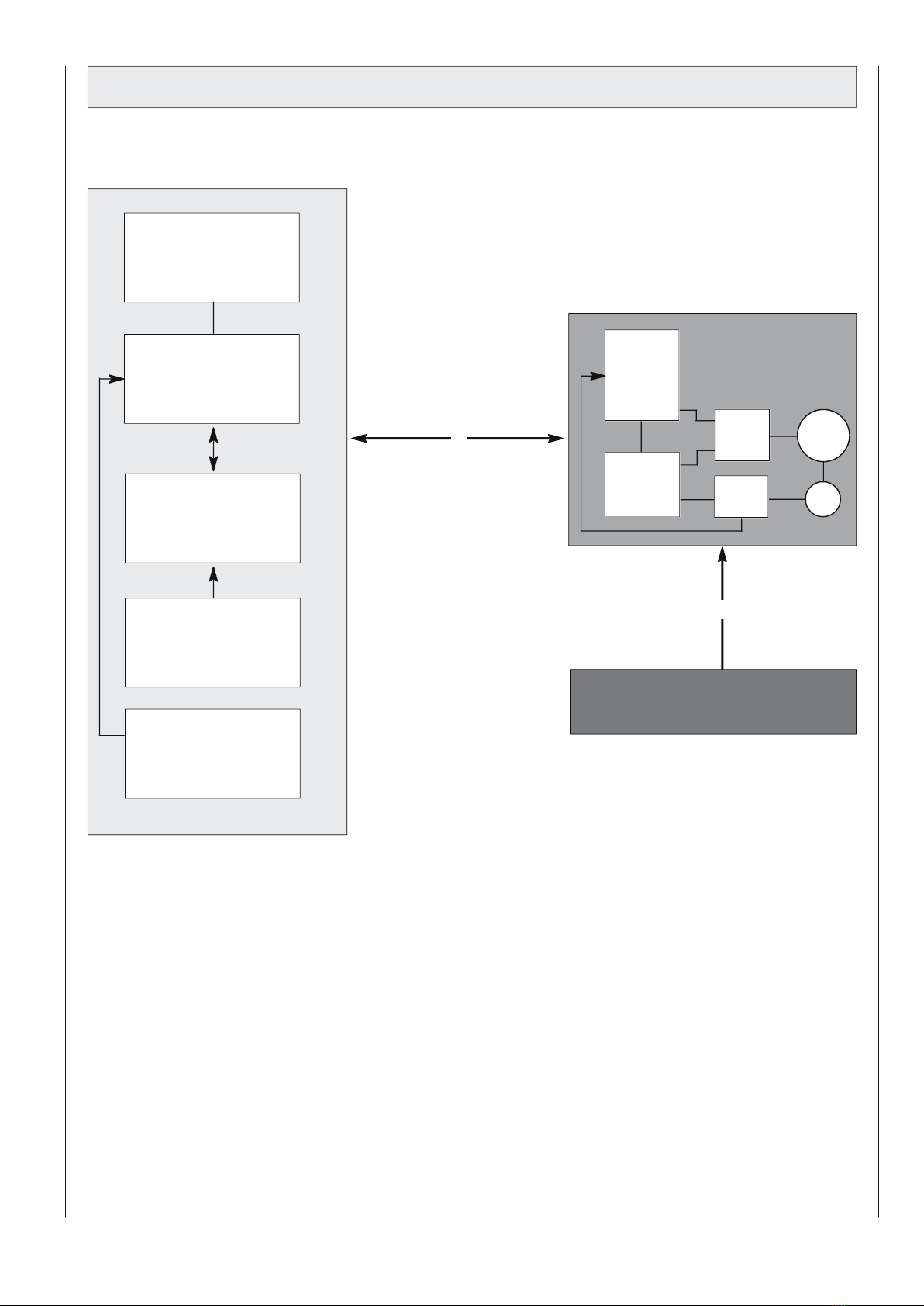

5. Block diagram of the electronic

parts ARTROMOT®-K1

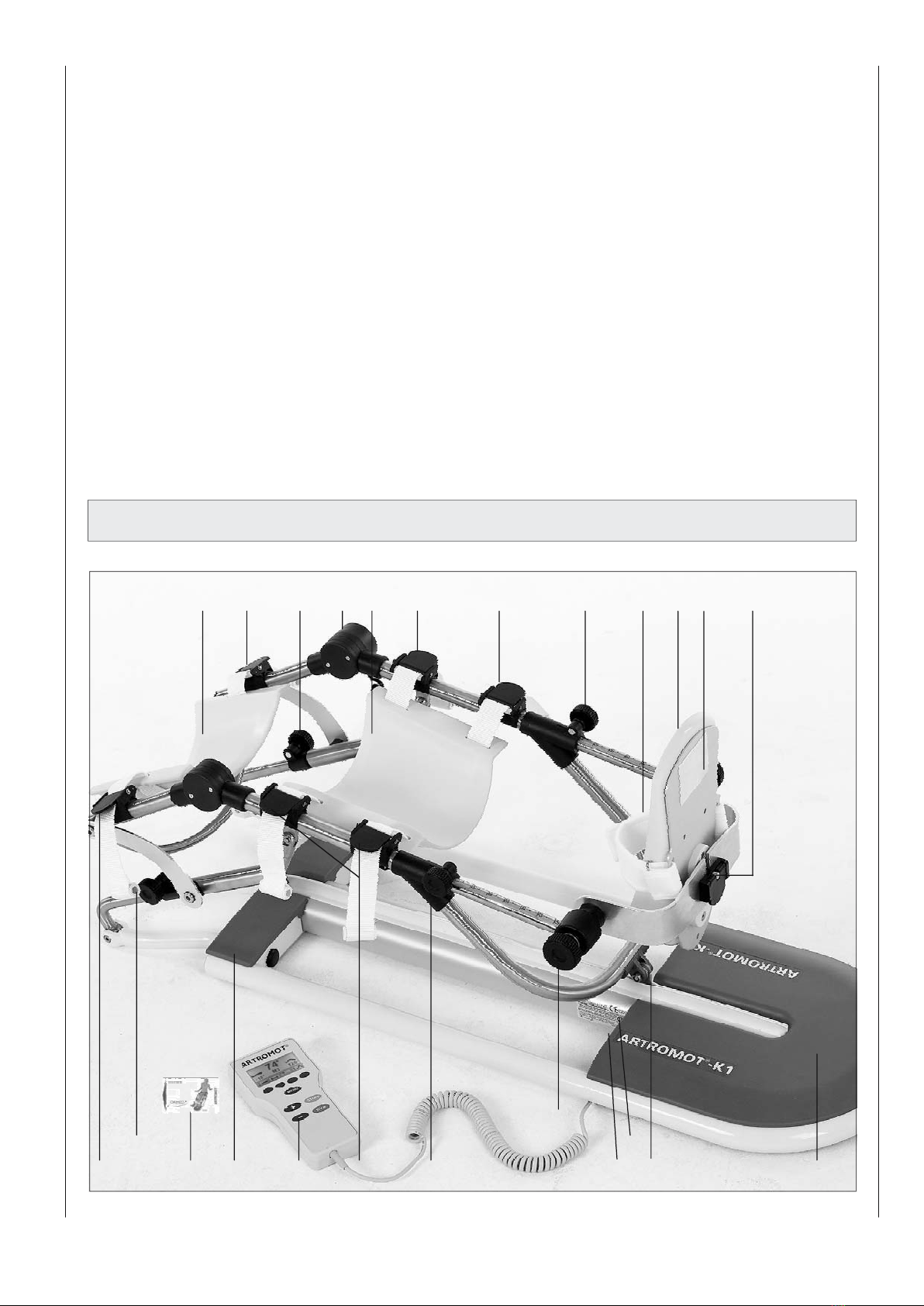

6. Bill of material for service parts ARTROMOT®-K1

7. Figure for bill of material

8. Special function Service menu for

ARTROMOT®-K1Comfort and Standard version

9. Special function Service menu for

ARTROMOT®-K1Classic

10. How to perform repairs

11. Checklist of safety and function test

ARTROMOT®-K1Comfort and Standard version

12. Checklist of safety and function test

6

7

8

10

12

14

15

16

simple repairs on the ARTROMOT®-K1. Only authorized

staff may perform repairs and maintenance as the manufac-

turer’s warranty and liability would otherwise be invalidated.

Only original parts may be used for servicing in accordance

the attached spare parts list.

1

2

3

4

unit is switched on. Always switch the ARTROMOT®-K1

off before connecting or disconnecting a plug.

The locks for spiral cable for the hand-held program-

ming unit have to be closed at all times.

When you assembling with electronic parts make sure

to use ESD (Electro Static Discharge) equipment.

Only original chip cards may be used. Insert the chip

cards so that ARTROMOT® is visible.

If you have to exchange any of the printed circuit boards

including the knee electronics, hand held programming

unit, motor control or power supply electronics you have

to perform a calibration.

Possible errors: Errors will be displayed on the hand-

held programming unit as follows shown:

Wrong angle information

-> Replace knee electronics (Pos. 5)

-> Replace motor control (Pos. 25)

Connection to the potentiometer is interrupted

-> Replace knee electronics (Pos. 5)

-> Replace motor control (Pos. 25)

The motor driver IC reported an error

The motor did not turn properly

-> Replace the motor (Pos. 26)

1 10.02.2006 S. Herr Service Manual

created

2 14.07.2006 S. Herr Pos. 25,

chapter 10

3 14.08.2006 S.Herr Pos. 20,

Chapter 9, 12

XX