MiPNet15.03 O2k-MultiSensor-ISE 10

Oroboros Instruments Mitochondria and cell research

Short term: Place the tip of the electrode in a test

tube or beaker containing reference electrolyte (3 M

KCl). Falcon type 15 mL vials are well suited. If

necessary, refill electrolyte before use.

Long-term (>4 weeks): Remove the glass barrel

containing the electrolyte and store the entire glass

barrel in a closed test tube filled with the reference

electrolyte. Rinse the silver wire and electrode cap to

remove the salt solution and dry using an absorbent

towel. Store in the accessory box or any closed

container to keep dust off the electrode and protect

from light.

Troubleshooting: Try to locate the problem either at the measuring

ISE or at the reference electrode by switching

electrodes. If you have only one reference electrode

you can switch to a spare glass barrel for diagnostic

purposes. The following text assumes that the problem

was located on the reference electrode.

Little or no response: Inspect the electrode for visible cracks.

If any exists, the glass barrel is defective and must be

replaced with a spare. The slightest crack in or around

the tip of the electrode may cause the electrode to read

about the same signal in all solutions.

Response pegs OFF scale: 1) Check the pX gain setting.

2) Visually inspect the electrode for broken or

dissolving internal Ag-AgCl wire or for inadequate

volume of reference electrolyte. Reference electrolyte

level should be above the Ag-AgCl element.

3) Blocked or clogged liquid junction –first clean

electrode tip, then soak it in warm (not hot) distilled

water for 5 to 10 min. If still clogged, remove the wire

from the glass barrel, clean the barrel with distilled

water, then soak it in distilled water. Next, clean it with

enzyme cleaning solution such as Terg-a-zyme

(Alconox, Inc.) to remove protein from the reference

junction. If still clogged, replace reference barrel with

spare barrel supplied.

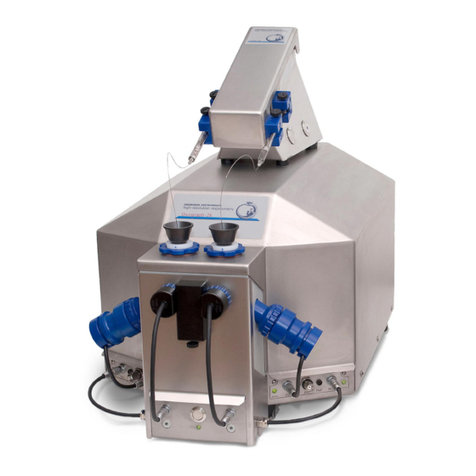

3. O2k-MultiSensor system

The O2k-FluoRespirometer supports all add-on O2k-

Modules and includes all O2k-MultiSensor channels

mentioned below. For O2k- Series B and C see

Appendix.

Before handling the BNC plugs (on the O2k-Main

Unit) and connecting the electrodes, always touch the