2

Ortlieb Präzisionssysteme GmbH & Co. KG • Jura Str. 11 • 73113 Zell u. Aichelberg • Germany

Tel.: +49 (0) 7164 79 70 1-0 • Fax.: +49 (0) 7164 79 70 1-51 • e-mail: info@ortlieb.net • www.ortlieb.net

Content:

1

Gerneral.................................................................................................................................3

1.1

Introduction.....................................................................................................................3

1.2

Guarantee......................................................................................................................4

1.3

Intended Use..................................................................................................................5

1.4

Initial start-up..................................................................................................................5

2

Product description ................................................................................................................6

2.1

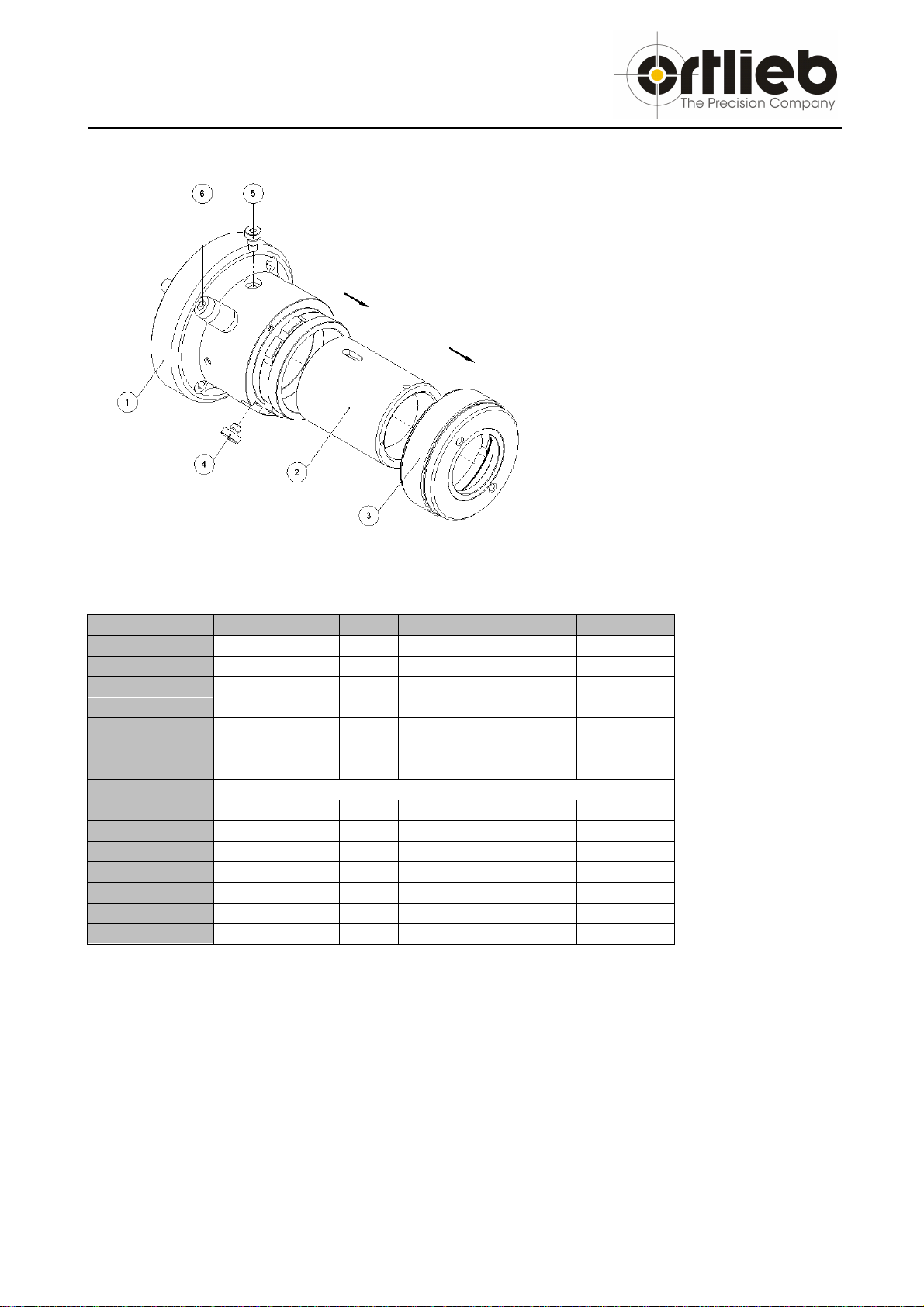

Component-overview......................................................................................................7

2.2

Technical Data ...............................................................................................................7

2.3

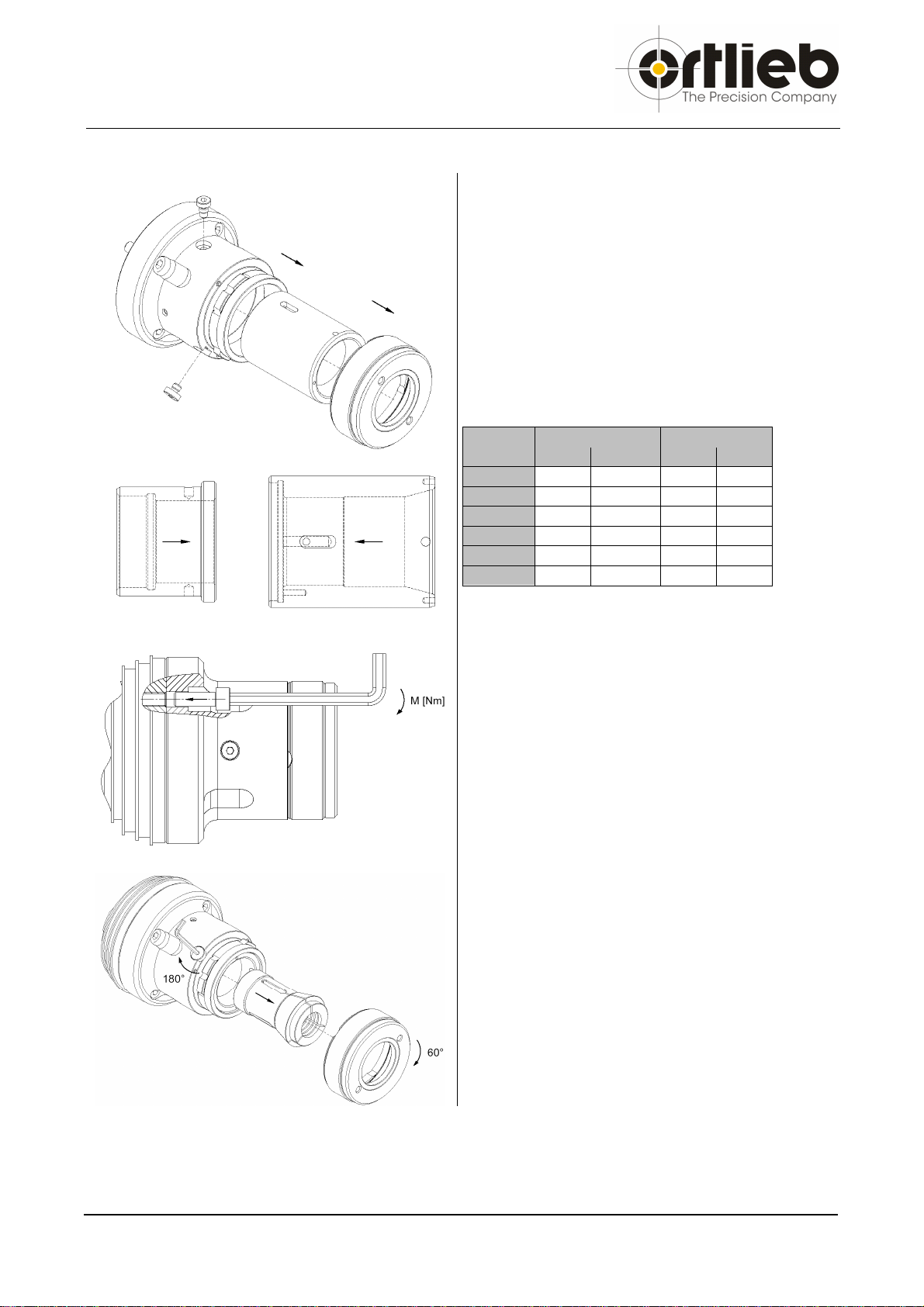

Mounting instructions......................................................................................................8

2.4

Check run-out.................................................................................................................9

2.5

Change the collet............................................................................................................9

3

Accessory ............................................................................................................................10

3.1

Spare parts...................................................................................................................10

3.2

Reduction parts............................................................................................................11

3.3

Twin-chucking ..............................................................................................................11

4

General Safety Instructions..................................................................................................12

5

Troubleshooting ...................................................................................................................14

6

Assembly declaration...........................................................................................................15

7

Shipping data.......................................................................................................................16