OSKA 6 Series User manual

oska.uk.com | 0845 381 0600 1

SERIES6

USER INSTRUCTIONS

2 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 3

PLEASE READ THE FOLLOWING INSTRUCTIONS

CAREFULLY AND OBSERVE THE WARNING

INSTRUCTIONS BEFORE USING THE SYSTEM.

CONTENTS

Know your symbols.............................................................................

About your mattress...........................................................................

Design features......................................................................................

How to set up your mattress..........................................................

Directions for powered use.............................................................

Removing control unit....................................................

Power interruption...........................................................

Patient transport...............................................................

Head-of-bed elevation...................................................

Electromagnetic or other interference..................

Troubleshooting patient complaints.......................

General directions................................................................................

Cleaning....................................................................................................

EMC Emisisons......................................................................................

Technical description..........................................................................

Specication...........................................................................................

Troubleshooting....................................................................................

Warranty....................................................................................................

Maintenance and repair log.............................................................

4

5

7

9

12

13

13

13

13

14

14

14

16

20

24

25

26

28

29

CHANGING LIVESTM

oska.uk.com

0845 381 0600

4 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 5

WARNING or CAUTION

Protection against the

ingress of ngers or similar

objects and dripping water

WARNING: Situations or actions that

may have an effect on patient or user

safety. Ignoring a warning could cause

patient or user injury.

Authorized representative

in the European

Community

CAUTION: Points out special

procedures or precautions that persons

must obey to avoid equipment damage.

Potential trip hazards

See the user manual for use instructions Manufacturer

Electrical shock hazard warning Double insulated system

WEEE Electromagnetic Emissions

Type BF applied part Electrical Safety

European conformity marking Keep Dry or Do Not Wet

Foot end Not made with natural

rubber latex

Alternating current Quantity

Serial number Catalogue number

Non sterile Batch code

Humidity limitation Temperature limitation

Direct current

KNOW YOUR SYMBOLS

This manual contains different typefaces and symbols to make the content

easier to read and understand:

Standard text - used for regular information.

Boldface text - stresses a word or phrase.

NOTE: - sets apart special information or important instruction clarication.

ABOUT YOUR MATTRESS

The OSKA Series6 features a

proprietary system of interconnected

air support cylinders designed to deliver

outstanding pressure redistribution for

those with or at risk of skin breakdown.

The OSKA Series6 is intended for use as

a non-powered reactive therapy surface,

or as a powered active therapy surface

via the addition of a powered air control

unit.

DESCRIPTION:

The system consists of a foam shell

with a high-density, zoned foam top

layer that serves as the interface

between the patient and the inner air

system. The foam shell also includes a

contoured Safety Edge™ foam bolster

design, providing added patient stability

and positioning. OSKA Series6 also

includes the unique Heel Slope® feature,

designed to further reduce pressure

for the vulnerable heel area. Within

the foam shell is housed the ination

system, consisting of air cylinders

running lengthwise within the mattress.

One of two different, optional add-on

powered control units can be connected

to the mattress to provide alternating

pressure or powered otation modes.

The system also includes an auto rm

mode to provide a rm support surface

for use during patient care and to assist

during patient transfer. Built-in check

valves ensure an ideal therapeutic

setting for non-powered pressure

redistribution when the control unit is

not attached.

INDICATIONS FOR USE:

The OSKA Series6 model is intended

as an aid in the prevention and

treatment of pressure ulcers. Powered

modes are intended for active wound

treatment, and may be indicated for

use as a preventive tool against further

complications associated with critically

ill patients or immobility.

1. Use this unit only for its intended

use and with recognised accessories

which are described in the operating

instructions; use of other accessories

or materials may degrade minimum

safety level.

2. Never operate the product’s

powered control unit if it has a

damaged cord or plug, is not

working properly, has been dropped

or damaged, or has been exposed to

water. Return the unit to OSKA.

3. Keep the cord away from heated

surfaces. Discontinue use if power

cord is damaged or worn.

4. Never drop or insert any object into

any opening or hose. Keep away

from sharp objects.

5. Do not use outdoors.

CAUTION!

The Series6 is not for use by

those with unstable spinal

chords

WARNING!

To reduce the risk of burns,

electrocution, re or injury

to persons: READ ALL

INSTRUCTIONS BEFORE USING

THIS UNIT.

6 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 7

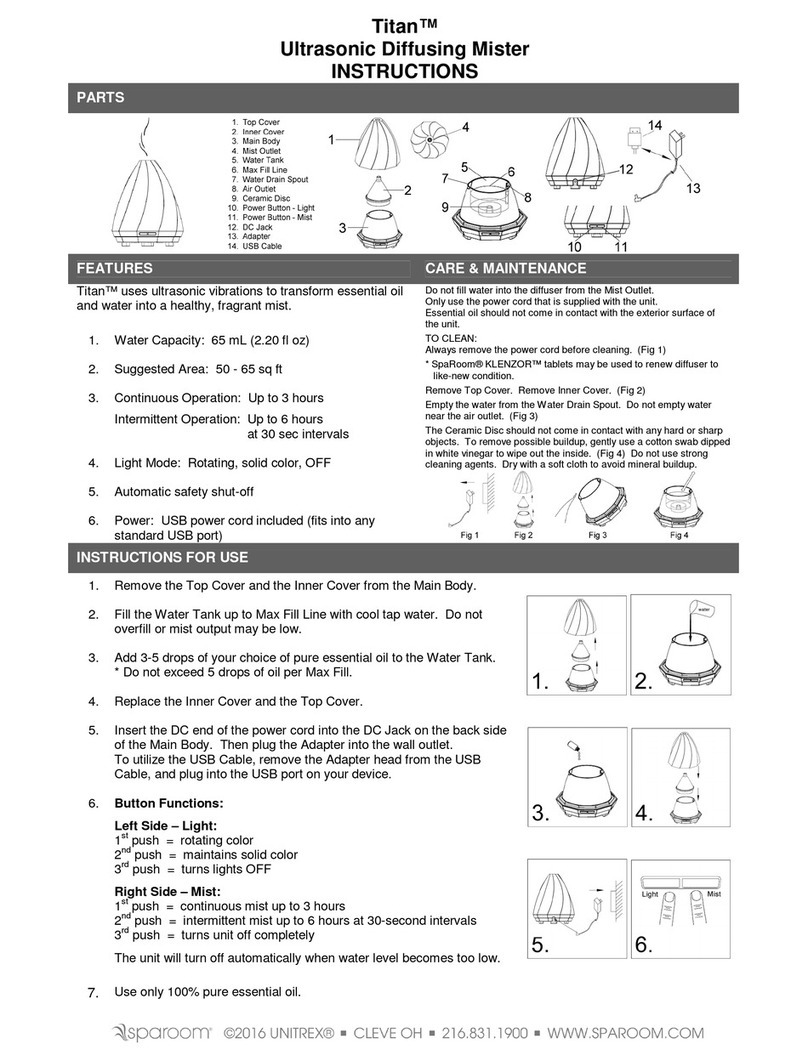

DESIGN FEATURES

6. Do not place or store product where

it can fall or be pulled into a tub or

sink.

7. Do not place in or drop into water or

other liquid.

8. Do not reach for a product that

has fallen into water. Unplug

immediately.

9. Possible explosion hazard if used

in the immediate proximity of

ammable gases (risk of explosion).

10. Use only original spare parts and

consumables.

11. Plug this product into a correctly

grounded outlet only.

12. Before cleaning, unplug unit from

its power source. Failure to do so

could result in personal injury or

equipment damage.

13. Do not use harsh cleansers, solvents,

or detergents. Do not expose

the unit to excessive moisture.

Equipment damage could occur.

V-GUARDTM Cover

Foam shell with Geo-Matt® topper

Safety Edge™ bolster system

Interconnected support cylinder system

1

2

3

4

8 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 9

HOW TO SET UP YOUR

MATTRESS

1. Place the Series6 mattress on the bed

frame with the airline connectors at

the foot end of the bed. The mattress

has a black bottom cover that should

be placed directly on the bed frame,

the mattress cover will have airline

connecters on the bottom left corner,

make sure this matches with the

airline connecters on the mattress.

The blue top cover should face

upwards, with the foot icon at the

bottom of the bed frame.

2. Check the bed frame is appropriate

for use with the mattress, i.e. the

length and width of the mattress

are appropriate for the frame. Place

directly on a healthcare bedframe

only, never on top of another

mattress.

3. The mattress is now ready for use

in the non-powered mode (that is,

without the powered control unit

attached) by users who are within the

500 lbs. (226 kg) weight limit for the

product [400 lbs. (180 kg) in powered

mode].

4. The surface is designed to be used

with appropriate linens in place. See

page 14.

CONNECTING OPTIONAL POWERED

CONTROL UNIT:

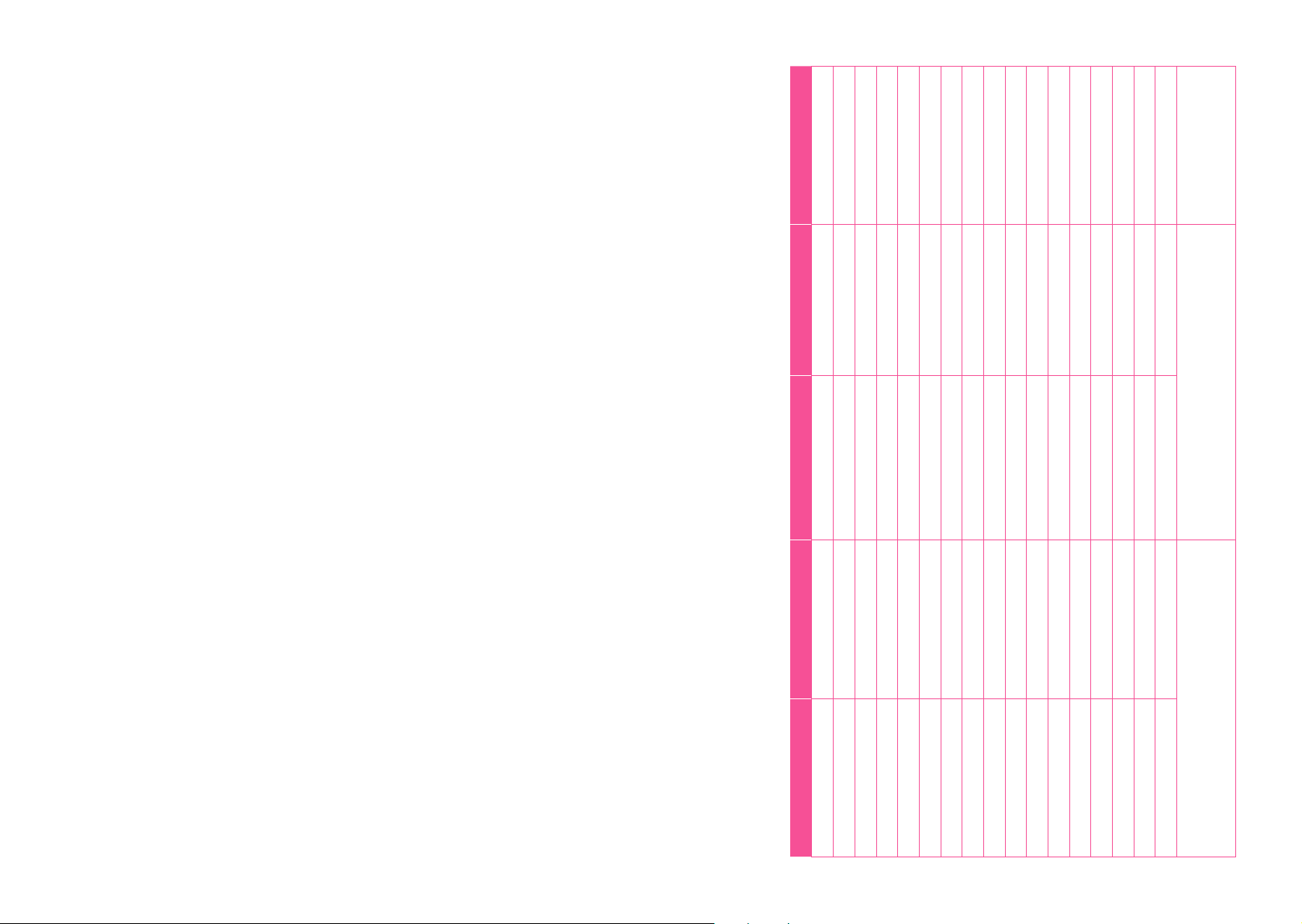

1. Hang the control unit on the foot

board at the end of the bed using

fold-out hangers (gure a). Connect

airlines to control unit by pressing

quick connector into port on the

side of unit. “Triangle” symbol should

face front. (gure b) audible “click”

indicates secure connection.

NOTE: The hanger lock strip (included,

item # P10064, Fig. C) can be used to

help hold control unit more snugly in

place on thin footboards such as those

often found on home health care beds.

To use, place the strip in position around

the hanger hooks as shown in Figure D.

DESIGN FEATURES

1.

V-GUARDTM cover

with Shear Transfer

Zones ™

Outer cover features a bi-directional stretch fabric designed to allow full

integration of the user into the surface. Top is made from proprietary

polycarbonate-fortied healthcare fabric, which provides high resistance to

the damaging effects of diluted bleach and other aggressive cleaners and

disinfectants. It wipes clean easily with standard, hospital-grade cleaners. It

has a low moisture vapour transmission rate (MVTR).

Patented “Shear Transfer Zones” incorporated beneath top fabric creates

shear-minimizing bands beneath heels, sacrum and scapula. Zones help

prevent these bony prominences from digging into the surface, while

protecting against the damaging effects of micro shear, macro shear, and

rotational (pivot-induced) shear. Design also helps

“glide” the user back to their original position following HOB elevation.

Exclusive split bottom design helps reduce sliding of mattress while also

reducing the “gatching noise” typical of non-slip fabrics.

2.

Foam shell with

Geo-Matt® top

surface

The clinically proven Geo-Matt® segmented design incorporated into the top

surface of the mattress is a high-density, medical grade foam. The unique

geometric design consists of over 800 individual cells, each of which acts

individually to redistribute pressure, to reduce heat and moisture build-up

on the skin, and to reduce shear to underlying tissues. This foam topper is

approximately 2” in height and tapered at the foot end of the mattress. The

unique Heel Slope® feature helps further reduce interface pressures on

vulnerable heels.

3.

Safety Edge™

bolster system

The supportive Safety Edge™ consists of engineered inner and outer foam

bolsters for added patient stability in sitting and lying down.

4.

Proprietary air

cylinder system

The air system consists of four interconnected support cylinders arranged

longitudinally (head-to-foot) and constructed from RF- (radio-frequency)

welded urethane. The system is designed to provide and maintain low

interface pressures throughout the mattress in the non-powered mode.

When the powered control unit is attached, it provides active therapy in the

alternating pressure mode via ination and deation in a xed 10-minute

cycle. The system requires no adjustment or maintenance for the ve-year

duration of its warranty.

5.

Control Unit

options:

Model 5900 Digital Control Unit. Model 5500 Standard Control Unit.

Figure B

WARNING!

The t of the mattress to

the bed frame is important.

Minimizing spaces or gaps

between the mattress and

frame will help prevent patient

entrapment issues.

Figure A

10 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 11

2. Connect the ends of the air lines

with two right angle male connectors

(Figure E) to the ports on the side

of the mattress. Ports are located

beneath a fabric ap near the right

corner at the foot of the mattress.

Ensure that the air lines are not kinked

or twisted. Press connectors into

ports until you hear an audible “click”

for each. Press ap closed.

3. Ensure that green On/Off switch

at side of control unit is “Off”. Plug

power cord into wall outlet. Press On/

Off switch “ON”.

Figure C Figure D

4. When power switch is turned to

ON, the unit will power up in “Auto

Firm” mode and begin performing a

system check. This lls the air system

completely, in order to conrm the

proper connection and function of

both the mattress and the control

unit prior to a patient being placed

on the surface. If the mattress is

completely empty of air, this can take

as long as 20 minutes. You must leave

the mattress for a full 20 minutes to

fully inate before using or trying to

change the comfort level setting.

5. System will remain in “Auto Firm”

mode until this process is complete.

“Low Pressure” indicator light and

audible alarm will remain on as well.

Audible Alarm can be disengaged

during this process by pressing the

Audible Alarm On/Off button.

6. When system check is complete, the

control unit will revert to previous

comfort setting and “Alternate” mode.

Low Pressure indicator light will turn

off. System is now ready to be set for

the next user.

NOTE: If “Low Pressure” remains on

after 30 minutes, call for service.

Do not connect the power

cord to an extension cord or

to a multiple outlet strip. If

the use of extension cords or

multiple outlet strips cannot be

avoided, use only heavy duty or

hospital-grade connectors that

Do not cover the power cord

with a rug or carpet. Rugs or

carpets can prevent normal air

ow, which can lead to greater

heat built-up. Place the cord in

a low or no trafc area. Check

to be sure the motion of the

bed does not interfere with the

bed’s power cord or plug.

WARNING!

To avoid potential for injury to

patient’s foot, the control unit

should be positioned such the

hangers remain ush to the

headboard and do not extend

on to the sleep surface. This

may require use of the hanger

lock strip. See NOTE above.

Figure E

CAUTION!

Do not cut air lines to increase

separation. If additional

separation is needed to connect

air lines to the mattress, gently

pull air lines away from one

another to lengthen the split.

CAUTION!

Never thread air line through

mechanical parts of the bed

or bed rails where normal bed

movement may damage the air

lines or the air control unit itself.

Check to be sure the motion of

the bed does not interfere with

the air lines.

WARNING!

Always plug the power cable

securely into the wall outlet.

Make sure the wall-mounted

outlet will accommodate a

heavy duty or hospital-grade

plug and that the outlet is in

good working order. The plug

of the power cord should t

tightly into the wall outlet.

The plug body, the wall outlet,

and the wall plate should not

be cracked or chipped. The

plug blades should be securely

retained in the plug body. The

ground pin of the plug should

be intact and secure.

are approved by the facility.

Multiple outlet strips should

be mounted on a xed object

to reduce the risk of liquid

spills and physical damage. In

addition, if multiple-receptacle

outlet boxes are used, they

also should be protected from

the risk of liquid spills and

physical damage. All extension

cords and multiple outlet

strips should be tagged and

inspected routinely.

12 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 13

DIRECTIONS FOR POWERED USE

WEIGHT LEVEL SELECTION

Use the +/- buttons to set according to

the patient’s weight. Use the chart on

the front of the pump to select the right

setting.

MODE SELECTION: PRESS BUTTON TO

SELECT “ALTERNATE”, “FLOAT”, OR

“AUTO FIRM”.

“ALTERNATE” MODE:

Creates an “A-B” sequence of ination

and deation of the mattress’s four air

cylinders designed to change loading

across the surface in a 10-minute

cycle. In this mode, air cylinders 1 and

3 inate while 2 and 4 deate. After

approximately 5 minutes, the pattern

reverses.

“FLOAT” (POWERED FLOTATION

THERAPY) MODE:

Suspends cyclical ination/deation of

the air cylinders and instead provides

powered otation therapy. In this mode,

all four air cylinders are evenly inated,

and the system maintains ideal pressure

management by adjusting in response

to any repositioning of the user on the

surface.

“AUTO FIRM” MODE:

Suspends cyclical ination/deation and

sets system to rmest ination level for

20 minutes to facilitate user transfer,

feeding, dressing changes, and other

activities of daily living (ADLs), and CPR.

After 20 minutes, system will revert to

previous comfort setting and “Alternate”

mode.

POWER FAILURE AND LOW PRESSURE

ALARMS:

AUDIBLE ALARM ON/OFF: When

indicator light is on, an audible alarm

will sound if either the Low Pressure or

Power Failure indicator light is on. Press

button to silence the alarm. Alarm can

also be toggled off in advance if audible

alarm is not desired for low pressure

conditions.

POWER FAILURE:

During power failure situation or

upon power down, the Power Failure

indicator light will come on and the

audible alarm will sound. Press the mute

button to silence the alarm. (See “Power

Interruption”, below.)

LOW PRESSURE:

If “Low Pressure” indicator light comes

on after initial set-up or when moving

mattress or control unit, rst check that

all air lines are properly connected and

that they are not kinked. If light is still on

after 30 minutes, call for service.

REMOVING CONTROL UNIT:

To ensure effective non-powered

performance, DO NOT leave the control

unit attached to the OSKA Series6

mattress when powered operation is

no longer desired. Instead, disconnect

the control unit from the air ports at the

mattress. This will allow the air system to

reset to its ideal, non-powered ination

level.

POWER INTERRUPTION:

The OSKA Series6 is designed to

eliminate concerns related to loss

of power. In the event of a power

interruption during powered use, the

system will maintain a safe level of

patient support. However, to maximise

patient support and comfort during

power interruptions, simply disconnect

the mattress air lines at the control

unit, or at the mattress port. In either

case, the air system in the mattress will

reset to its ideal non-powered ination

level.

PATIENT TRANSPORT:

The OSKA Series6 is designed to

facilitate patient transport. For transport

when the powered control unit is in use,

simply disconnect the air lines from the

control unit and reconnect when patient

has reached destination. In the non-

powered mode, no action is required.

NOTE: Transport cap is not intended for

use with OSKA Series6

HEAD-OF-BED ELEVATION:

All support surfaces using air as a

support medium are designed for

distributing pressures over the body

in a at, horizontal position. Bending

the support surface and the body at

the midpoint when elevating the HOB

concentrates the body weight over

WARNING!

DO NOT MOVE USER ON

MATTRESS ONLY. Mattress

should not be used alone for

user/patient transport.

14 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 15

and state laws/guidelines, and by

individual facility protocol. It is the

responsibility of the facility to be in

compliance with these laws, which

typically require that decisions on the

use of bed rails of any type are based on

assessment of the physical and mental

status of each patient individually. If

bed-rails are needed by the patient to

prevent fall-related injury, as determined

by this facility assessment, we

recommend that the bed-rails be locked

in the up position at all times. We do

not require use of bed-rails unless the

patient is deemed to be safer with them

than without them.

CPR:

The Standards for Life Support

recommended by the American Heart

Association suggests a hard level

surface for performing CPR. This

means moving the person to the oor if

possible. If that is not possible, do the

following: For performing CPR:

1. Press “Auto Firm” Button

2. Place a crash board beneath the

patient.

3. Follow CPR procedures.

STORAGE AND TRANSPORTATION:

Store the mattresses in a clean, dry

the centre of the surface, stressing that

small area. This extreme change in

dynamics creates a challenge for all air

support surfaces. Maximum pressure

management benets are realized

between zero and 30° HOB elevation.

Beyond 30°, the amplitude of the

changes in the air cylinders begins to

decrease in proportion to the increased

elevation of the HOB. Although the

mattress will maintain its support and

therapeutic capabilities up to and

including 70° HOB, for maximum benet

we recommend that any pressure

management surface be used with the

head of the bed elevated as little as

possible, and for limited periods at a

time.

ELECTROMAGNETIC OR OTHER

INTERFERENCE

This equipment generates, uses and can

radiate radio frequency energy and, if

not installed and used in accordance

with the instructions, may cause harmful

interference to other devices in the

vicinity. However, there is no guarantee

that interference will not occur in a

particular installation.

If this equipment does cause harmful

interference to other devices, which can

be determined by turning the equipment

off and on, the user is encouraged to

try to correct the interference by one or

more of the following measures:

- Reorient or relocate the receiving

device.

- Increase the separation between the

equipment.

- Connect the equipment into an outlet

on a circuit different from that to which

the other device(s) are connected.

- Consult the manufacturer for help.

TROUBLESHOOTING/PATIENT

COMPLAINTS:

Occasionally a patient may complain

of feeling as if he/she is “sinking into a

hole”.

1) This may occur when the head of the

bed is elevated and the mattress is

in alternating pressure mode. This

sensation is a combination of the

deation of the cylinders during their

cycle and the increased weight of

the patient on the sacrum and pelvis

when the head of the bed is elevated.

This demonstrates the need to

minimize elevation of the head of the

bed, or to select alternating pressure

mode if HOB elevation is necessary.

2) A patient may complain when he/

she is supine or side-lying and are

not used to the changing pressures

within the air system. Reassure the

patient that this is normal functioning,

as the cylinders alternately inate

and vent. The vented tubes are not

fully deated. Some air is always

maintained in them to prevent

bottoming out. After reassurance,

patients typically become acclimated

to the changing pressures.

GENERAL DIRECTIONS

BED LINENS:

Seven-inch deep tted sheets are

recommended. Multiple layering of linens

or underpads beneath the patient should

be avoided for the prevention and

treatment of pressure ulcers.

BED RAILS:

Due to concerns over the possibility of

patient entrapment, OSKA recognises

that the use of rails of any length is a

matter currently addressed by federal

CAUTION!

Be careful not to puncture the

mattress with needles or sharp

instruments. This may result in

loss of integrity of the cover or

internal air system. Regularly

inspect the mattress cover for

cuts, rips, cracks or tears.

Do not use the mattress if the

cover is damaged.

place. Once the mattress is removed

from the box, store in a at position if

possible. Protect from damage. Avoid

temperature extremes (below freezing

or above 120° F/50° C). Allow to

acclimate to room temperature before

use. Do no stack more than 10 high. Do

not stack other equipment on top of the

mattresses.

Store and transport control units in

a clean, dry place, protected from

accidental damage or falls. Avoid

temperature extremes (below freezing

or above 120° F/50° C); suggested

storage and transportation temperature

60° to 120° F (15~50° C), humidity

40%~80%. Do not stack other

equipment on top of the control unit.

For transportation, secure to prevent

damage or falls. For shipment, use

box and packaging as provided by the

manufacturer.

ENVIRONMENTAL CONDITIONS FOR

USE:

• Indoor Use

• Altitude up to 6,500’ (2,000 meters)

• Temperature 40°F to 95°F (5°C to 35°C)

• Maximum relative humidity 80% for

temperatures up to 87° F (31° C),

decreasing linearly by 50 percent

relative humidity at 104° F (40° C)

• Mains Supply Voltage Fluctuation up

to 10 +/-% of the nominal voltage

• Over-voltage Category II

• Pollution Degree 2

WARRANTY:

The OSKA Series6 is unconditionally

guaranteed against failure due to

manufacturing defects under normal use

for 18 months for the control unit and 5

years for the mattress. See page 28.

16 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 17

USE IN WOUND CARE:

Use of the OSKA Series6 is only one

element of care in the prevention and

treatment of pressure ulcers. Frequent

repositioning, proper care, routine skin

assessment, wound treatment and

proper nutrition are but a few of the

elements required in the prevention

and treatment of pressure ulcers.

As there are many factors that may

inuence the development of a pressure

ulcer for each individual, the ultimate

responsibility in the prevention and

treatment of pressure ulcers is with the

health care professional.

CLEANING.

V-GUARDTM CLEANING AND

AFTERCARE GUIDELINES.

OSKA V-GUARDTM technology covers

are durable but, as medical devices,

they need treating with great care. The

surface is vapour permeable so it is

waterproof, but breathable to reduce

sweating of patient. This outer barrier

must not be penetrated. Even the

smallest breach of this barrier will cause

uid to penetrate the mattress.

There are specic cleaning and care

instructions that need to be strictly

adhered to prolong the life of the

product.

GENERAL GUIDELINES

Do not puncture the mattress with

needles or sharp instruments. This may

result in loss of integrity of the mattress

air system and will void the warranty.

Inspect the covers and zipper area for

signs of damage, puncture, or wear

that could result in uid pass-through.

If the cover is stained, soiled, or torn,

inspect the internal components for

signs of contamination. If contamination

is evident, quarantine the mattress and

remove from service following infection

control procedures.

The air control unit should be dusted

every 30 days and cleaned with a damp

cloth and mild detergent.

AIR FILTER PREVENTIVE

MAINTENANCE:

The air lter for the Control Unit

should be checked routinely for signs of

dirt or contamination.

The frequency for cleaning depends on

the air quality. The air lter is accessible

from the backside of the Control Unit.

As the lter is white, the need to clean

is obvious. Simply turn the controller

off and remove the plastic cover,

remove the lter, and hand wash using

warm water and mild detergent. Rinse

thoroughly and allow to air dry. Replace

the lter and the plastic cover.

DELAMINATION:

Delamination is when the layers within

the structure of the mattress cover

separate. This can be caused by using

incorrect chemicals or too high a

concentrate of cleaning chemicals on

the surface.

HOW TO PREVENT DELAMINATION:

OSKA V-GUARDTM Technology covers

incorporate a special layering system

to make them much more resistant to

delamination than many other mattress

covers. However, to help prevent

delamination:

1. Always abide by the cleaning

instructions

2. Avoid using chemicals with too high

concentration.

3. Ensure cleaning chemicals are always

thoroughly rinsed off before allowing

to dry

4. The V-GUARDTM covers can tolerate

up to 10,000ppm chlorine but using

a weaker solution of 1,000ppm will

reduce the risk of a high concentrate

being left on the surface

5. Ensure the covers are thoroughly dry

before using or storing the mattress

Abrasive cleaning agents should

NOT be used.

In addition, due to the range

of cleaning chemicals and

conditioners being used, customers

should ascertain that any fabric

performs as expected, without any

adverse effect.

Some surface wrinkling may result

from cleaning procedures. This

1.1

1.2

1.3

should have no adverse effect on

the fabric’s properties.

If customers have their own

particular cleaning methods that

must be used and that are not

covered in this article, they should

consult OSKA for further direction

and guidance.

All polyurethane coatings need to

be treated with care when cleaning

the surface. Many industrial

cleaning agents are extremely

harsh on the coating and can cause

it to break down.

For supercial dirt use a disposable

wipe and a warm solution of

neutral detergent. Do not use

abrasive cleaners.

Disinfect in situ using 0.1% sodium

hypochlorite solution (1000ppm

available chlorine). Wipe off

any residue with clean water.

V-GUARDTM covers can tolerate

10,000ppm chlorine but using

a weaker solution of 1,000 ppm

will reduce the risk of a high

concentrate being left on the

surface.

The fabrics are able to be washed

in warm soap water at up to 95°C.

All cleaning agents and

disinfectants must be thoroughly

rinsed off and the item dried before

storage.

Spin and tumble dry on a low

setting (not more than 130°c. The

fabric surface may wrinkle but

this will not impede function). The

operator ensures it is removed as

soon as all moisture is removed.

The fabric must not be left sitting

on the heated bowl of the drier

when drying is complete.

Do not mangle.

Do not iron.

Store in a cool dry area.

Avoid excessive pressure and

always thoroughly dry fabric before

re-use or storage. Do not fold away

wet or store in damp conditions.

Keep away from sharp objects.

Regularly check the inside of the

cover for any signs of leakage

If the cover leaks then the

waterproof barrier has been

broken and a new cover should be

purchased from OSKA

1. GENERAL DIRECTIVES

1.4

2.1

2.2

2.3

2.4

2.5

3.1

3.2

3.3

4.1

4.2

4.3

5.1

5.2

5. DAMAGES AND REPLACEMENT

4. STORAGE

2. WASHING AND DISINFECTION

3. DRYING

18 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 19

STRIKETHROUGH:

Strikethrough occurs when the bres

in the mattress covers start to break

down. Small cracks develop, which on

inspection, may not be visible. This

means uids and other contaminates

can pass through the cover and

contaminate the core of the mattress.

HOW TO PREVENT STRIKETHROUGH:

Covers are most susceptible to

strikethrough damage when they are

wet. During cleaning, extra care should

be taken to avoid abrasion of the

surface. OSKA V-GUARDTM Technology

covers incorporate a special layering

system to make them much more

durable than many other mattress

covers. However, to help prevent

strikethrough:

1. Always abide by the cleaning

instructions

2. Avoid using chemicals with too high

concentration.

3. Ensure cleaning chemicals are always

thoroughly rinsed off before allowing

to dry

4. The V-GUARDTM covers can tolerate

up to 10,000ppm chlorine but using

a weaker solution of 1,000ppm will

reduce the risk of a high concentrate

being left on the surface

5. Ensure the covers are thoroughly dry

before using or storing the mattress

ROUTINE INSPECTION OF POWER

CORDS AND SAFETY TIPS TO

PREVENT FIRES

1. Assure that the electrical resistance

of the safety ground conductor

and the level of leakage current

(line conductor-to-safety ground

and neutral conductor-to-safety

ground) meet applicable standards

for resistivity and leakage current.

Protection afforded by the ground

pin is negated if the receptacle is

not properly grounded. If you have

questions about the adequacy of

your facility’s building wiring, contact

a qualied electrician or consult the

code authority in your jurisdiction.

2. Check all electrical outlets, including

accessory outlets for cleanliness,

physical integrity and functionality.

The IEEE standard 602-1996, section

4.2.2 advises that hospital-grade

outlets be used and that they should

be mounted with the ground pin or

neutral blade up to assure that any

metal that may drop between the

plug and the wall will most likely

contact an unenergized blade.

3. Check the power cord to assure that

contact pins are straight and secure

4. Routinely inspect the power cord for

damage sustained from crushing,

pinching, shearing, cutting, or from

being worn through. They can

be damaged by bed movement,

deterioration from use or aging, or

human or equipment trafc. The

cord’s insulation should be intact

and there should be no evidence

of bulging, stretching, crimping,

cracking, or discoloration, especially

at the ends, where the cord is

attached to the plug body and the

control unit.

5. Regularly inspect all parts of the bed

frame, motor, mattress and controller,

and the oor beneath and near the

bed for build-up of dust and lint.

6. Inspect the cover of the control panel

to assure that the covering is not

cracked or damaged, allowing liquids

or other conductive material to

penetrate to the switches.

7. Report any unusual sounds, burning

odours, or anything unusual to

maintenance personnel. Discontinue

use of the power cord immediately

and contact OSKA for replacement.

MATTRESS

Inspect the covers and zipper area for

signs of damage, puncture, or wear

that could result in uid pass-through.

If the cover is stained, soiled, or torn,

inspect the internal components for

signs of contamination. If contamination

is evident, quarantine the mattress and

remove from service following infection

control procedures.

You may use the Preventive Maintenance

Log provided on page 27 of this manual

to monitor and document regular

inspection and maintenance of your

OSKA Surfaces.

EMC

Electric devices may interact due

to electro-magnetic radiation. We

recommend a safety distance of at

least one meter, especially for sensitive

equipment.

Upon request, we will provide you with a

table for more detailed information.

20 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 21

Emissions Test Compliance Electromagnetic Environment-Guidance

RF emissions

CISPR 11 Group 1

The device uses RF energy only for its

internal function. Therefore, its RF emissions

are very low and are not likely to cause any

interference in nearby electronic equipment.

RF emissions

CISPR 11 Class B

The device is suitable for use in all

establishments, including domestic

establishments and those directly connected

to the public low-voltage power supply

network.

Harmonic emissions

IEC61000-3-2 Class A

Voltage uctuations

/ Flicker emissions

IEC61000-3-3

Complies

WARNING:

1. The device should not be used adjacent to or stacked with other equipment. If

adjacent or stacked use is necessary, the device should be observed to verify

normal operation in the conguration in which it will be used.

2. Use of accessories, transducers and cables other than those specied or

provided by the manufacturer of this equipment could result in increased

electromagnetic emissions or decreased electromagnetic immunity of this

equipment and result in improper operation.

3. Portable RF communications equipment (including peripherals such as antenna

cables and external antennas) should be used no closer than 30 cm (12 inches)

to any part of the [ME EQUIPMENT or ME SYSTEM],including cables specied

by the manufacturer. Otherwise, degradation of the performance of this

equipment could result.

GUIDANCE AND MANUFACTURER’S DECLARATION- ELECTROMAGNETIC

EMISSIONS:

This device is intended for use in the electromagnetic environment specied below.

The user of this device should make sure it is used in such an environment.

Electrical fast

transient/ burst

IEC61000-4-4

±2kV for power supply line

±1kV for input/out line

±2kV for

power supply

line

±1kV for input/

out line

Mains power quality

should be that of a

typical commercial or

hospital environment.

Surge

IEC61000-4-5

±1 kV line(s)

to

line(s)

±2 kV line(s)

to earth

±1 kV line(s) to

line(s)

±1 kV line(s) to

line(s)

Mains power quality

should be that of

atypical commercial or

hospital environment.

Voltage

dips, short

interruptions

and voltage

variations on

power supply

input lines

IEC61000-4-11

Voltage Dips:

i) 100% reduction for 0.5

period,

ii) 100% reduction for 1 period,

iii) 30% reduction for 25/30

period,

Voltage Interruptions:

100% reduction for 250/300

period

240V Mains power quality

should be that of a

typical commercial or

hospital environment. If

the user of this device

requires continued

operation during power

mains interruptions, it is

recommended that the

device be powered from

an uninterruptible power

supply or a battery.

Power frequency

(50/60Hz)

magnetic eld

IEC61000-4-8

3 A/m 30 A/m 30 A/m

Power frequency

magnetic elds

should be at levels

characteristic of a

typical location in a

typical commercial or

hospital environment.

Immunity Test IEC60601 test level Compliance Electromagnetic

environment-

guidance

Basic EMC

standard

Immunity

Test Levels

Professional

healthcare

facility

environment

Home

healthcare

environment

Electrostatic

Discharge (ESD)

IEC61000-4-2

±8kV contact

±15kV air

±8kV contact

±15kV air

Floors should be wood,

concrete or ceramic tile.

If oors are covered with

synthetic material, the

relative humidity should

be at least 30%.

22 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 23

Radiated RF EM

Fields

IEC61000-4-3

3 V/m 80

MHz to 2.7

GHz

80 % AM at

1 kHz

385-6000

MHz, 9-28V/

m, 80%

AM(1kHz)

pulse mode

and other

modulation

10 V/m 80 MHz

to 2.7 GHz

80 % AM at 1

kHz

385-6000

MHz, 9-28V/m,

80% AM(1kHz)

pulse mode

and other

modulation

10V/m Recommended

separation distance

d=√P 150kHz to 80MHz

d=0.6√P 80MHz to

800MHz

d=1.2√P 800 MHz to

2.7G MHz

Where P is the

maximum output power

rating of the transmitter

in watts (W) according

to the transmitter

manufacturer and d

is the recommended

separation distance in

meters (m).b

Field strengths from

xed RF transmitters,

as determined by an

electromagnetic site

survey,ashould be less

than the compliance

level in each frequency

ranged.

Interference may

occur in the vicinity of

equipment marked with

the following symbol:

NOTE 1: UT is the a.c. mains voltage prior to the application of the test level

NOTE 2: At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is

affected by absorption and reection from structures, objects and people

a) Field strengths from xed transmitters, such as base stations for radio (cellular/

cordless) telephones and land mobile radios, amateur radio, AM and FM radio

broadcast and TV broadcast cannot be predicted theoretically with accuracy.

To assess the electromagnetic environment due to xed RF transmitters, an

electromagnetic site survey should be considered. If the measured eld strength

in the location in which the device is used exceeds the applicable RF compliance

level above, the device should be observed to verify normal operation. If abnormal

performance is observed, additional measures may be necessary, such as

reorienting or relocating the device.

b) Over the frequency range 150 kHz to 80 MHz, eld strengths should be less

than 10 V/m.

Rated maximum

output power of

transmitter

(W)

Separation distance according to frequency of transmitter

m

150 kHz to 80 MHz

d=√P

80 MHz to 800 MHz

d=0.6√P

800 MHz to 2.7 GHz

d=1.2√P

0.01 0.1 0.06 0.12

0.1 0.31 0.19 0.38

1 1 0.6 1.2

10 3.1 1.9 3.8

100 10 6 12

For transmitters rated at a maximum output power not listed above, the

recommended separation distance using the equation applicable to the frequency

of the transmitter, where P is the maximum output power rating of the transmitter

in watts (W) according to the transmitter manufacturer.

NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher

frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic

propagation is affected by absorption and reection from structures,

objects, and people.

RECOMMENDED SEPARATION DISTANCES BETWEEN PORTABLE AND MOBILE RF

COMMUNICATIONS EQUIPMENT AND THIS DEVICE:

This device is intended for use in an electromagnetic environment in which radiated

RF disturbances are controlled. The customer or the user of this device can help

prevent electromagnetic interference by maintaining a minimum distance between

portable and mobile RF communications equipment (transmitters) and this

device as recommended below, according to the maximum output power of the

communications equipment

24 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 25

Item Specication

Power Supply (NOTE: See rating label on

the product)

AC 100-120V 60 Hz, 0.17A (for 120V system) AC

220-240V 50 Hz, 0.08A (for 230V system)

Fuse Rating T1A, 250V for 120 V system, T1AL 250V for 230V

system

Cycle time Fixed

Environment

Temperature Operation:10° C to 40° C (50° F to 104° F)

Storage: -15° C to 50° C (5° F to 122° F)

Shipping: -15° C to 70° C (5° F to 158° F)

Humidity Operation: 10% to 90% non-condensing

Storage: 10% to 90% non-condensing

Shipping:10 % to 90% non-condensing

Atmospheric

Pressure

Operation: 70 – 106 kPa

Storage: 50 – 106 kPa

Shipping: 50 – 106 kPa

Classication

Class II, Type BF, IPX0 for 120V system, IP21 for

230V system, Applied Part: Air Mattress.

Not suitable for use in the presence of a ammable

anaesthetic mixture (No AP or APG protection)

TECHNICAL DESCRIPTION

COVER:

Bacteriostatic, ame resistant, uid-

proof, tear resistant

FOAM:

High-density open-cell polyurethane.

Conforms to NFPA 101 small scale and

Cal TB# 117

AIR CYLINDERS:

Urethane

ELECTRICAL:

3200CEG: 220-240 VAC/50Hz., 0.08A

For 240V system:

CE marked in line with Medical Devices

Directive (93/42/EEC)

CONTROL UNIT:

3200CEG (UK)

Classication: Class II, Type BF

No AP or APG protection

Weight: 2.1kg

29.21cm x 17.78cm x 11.43cm

MATTRESS WEIGHT:

Approximately 9kg. (standard model

and Safety Supreme)

WEIGHT LIMIT:

180kg (pumped)

226kg (pumpless)

CYCLE TIME:

10 minutes (digital control unit)

8 minutes (standard control unit)

PLACEMENT:

All mattresses can be placed directly on

a healthcare bed frame.

SPECIFICATIONS:

26 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 27

Problem Possible Cause Solution

Low pressure

indicator illuminated.

Air lines not connected. Disconnect and reconnect air lines

to verify they have all locked into

place.

Air lines or quick disconnect

connectors are damaged.

Call for replacement.

Defective Control Unit. Call for service.

Leaking ination system. Call for replacement. To replace,

turn mattress upside down and

unzip cover. Remove ination

system, install new system, zip

cover and restore mattress to

upright position.

Interference

produced to

electronic

equipment/devices

in surrounding area.

Electromagnetic interference

caused by the unintentional

emission of electromagnetic

waves of energy. These waves

are transmitted through the air

at various frequencies which

may produce interference such

as abnormal functioning to

nearby electronic equipment.

Determine if emissions are causing

the interference by turning the

equipment off and on. If the

interference in the affected device

subsides when control unit is off,

proceed with the following steps.

a) Reorient or relocate the affected

device.

b) Increase the distance between

the equipment.

c) Connect the equipment into an

outlet on a circuit different than

that of the affected device.

d) Consult the eld service

technician or manufacturer of the

affected device.

TECHNICAL SERVICE: 0845 381 0600

TROUBLESHOOTING GUIDE:

Problem Possible Cause Solution

System will not

power up.

Note:

Always plug power

supply into properly

earthed receptacle.

The system is not plugged in. Plug power cord into wall

There is no power at outlet. Restore power

Power chord is damaged. Call for service

Blown fuse Call for service

Patient not turning/

alternating properly.

System is not turned ON Plug power cord into wall

Patient not centred on mattress Reposition patient

Patient has severe contractures Turning can be difcult to observe

in patients with severe contractures.

Observe someone without

contractures lying on the bed for

20 minutes (2 cycles) to conrm

turning is functioning properly

Head of bed is elevated, or

knees are gatched

The degree of patient turn achieved

is reduced with elevation of the

head of bed or gatching of the

knees. Adjust each as necessary

to meet patient needs while

maximizing turn angle

Defective control unit Call for service

Patient exceeds weight limit Call OSKA for alternative products

Mattress not

inating or patient

reports a sinking

feeling,

Control unit is not turned on Turn control unit on

Airlines not connected Ensure secure connection of airlines

at control unit and mattress

Airlines or quick disconnect

connectors are damaged

Call for replacement

Head of bed elevated Lower head of bed and allow

air to equalise. Return head of

bed to elevated position that is

comfortable for patient.

Defective control unit (mattress

lls without patient, sinks with

patient weight)

Call for service

TROUBLESHOOTING GUIDE:

28 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 29

FOAM AND CELLS - 5 YEARS

OSKA (the “Company”), warrants to

the original purchaser that the Series6

therapeutic support surface will be

free from defects in materials and

workmanship for a period of 5 years

from the date of purchase. During the

warranty period, the Company will repair,

or replace, with a new product which is

identical or reasonably equivalent to the

warranted product shown to be defective

in materials or workmanship. During

the full 5 years of the warranty period,

such repair or replacement will be made

without charge to the original purchaser.

All claims must be submitted in writing

and must be accompanied by the

Company’s original sewn-in label and

by the original invoice for the product

or a copy of the original invoice. All

transportation and handling costs

incurred in returning the system or any

component at any time throughout

the warranty period will be paid by the

Company when accompanied by a return

authorisation number.

CONTROL UNITS: 18 MONTHS

OSKA (the “Company”), warrants to

the original purchaser that the Series6

control unit will be free from defects in

materials and workmanship for a period

of 18 months from the date of purchase.

During the warranty period applicable to

the control unit for Series6 the Company

will repair, or replace, with a new product

which is identical or reasonably equivalent

to the warranted product shown to be

defective in materials or workmanship.

During the full 18 months of the warranty

period, such repair or replacement will

WARRANTY

V-GUARDTM COVER - 4 YEARS PRO RATA:

Year 1 - 100%

Year 2 - 75%

Year 3 - 50%

Year 4 - 25%

be made without charge to the original

purchaser.

All claims must be submitted in writing

and must be accompanied by the

product’s serial number and by the

original invoice for the product or a copy

of the original invoice. All transportation

and handling costs incurred in returning

the unit or any component at any time

throughout the warranty period will be

paid by the Company when accompanied

by a return authorization number.

This warranty specically excludes liability

for defects caused by improper use of

the system and use of the system without

the cover or otherwise contrary to the

approved instructions provided by the

Company.

Other than the warranties set out above,

the Company makes no other warranties

of any kind, expressed or implied, as to

merchantability, tness for any particular

purpose, or any other matter with respect

to the goods.

In no event, including, but not limited

to, cases of claims of negligence or

strict liability, shall the Company be

liable for indirect, incidental, special or

consequential damages, nor shall the

Company, in any event, be liable for

damages in excess of the purchase price

of the products claimed to be defective.

With regard to questions relating to the

WARRANTY, contact OSKA.

Date Air lter Power cord Mattress Repair

Manufacturer: OSKA

Date Purchased:

Serial Number/

D/O/B:

C=Cleaned

OK=Okay

R=Repaired/Replaced

SERIES6 PREVENTIVE

MAINTENANCE AND REPAIR LOG

30 oska.uk.com | 0845 381 0600 oska.uk.com | 0845 381 0600 31

Date Air lter Power cord Mattress Repair

Manufacturer: OSKA

Date Purchased:

Serial Number/

D/O/B:

C=Cleaned

OK=Okay

R=Repaired/Replaced

SERIES6 PREVENTIVE

MAINTENANCE AND REPAIR LOG

Date Air lter Power cord Mattress Repair

Manufacturer: OSKA

Date Purchased:

Serial Number/

D/O/B:

C=Cleaned

OK=Okay

R=Repaired/Replaced

SERIES6 PREVENTIVE

MAINTENANCE AND REPAIR LOG

32 oska.uk.com | 0845 381 0600

Edward House, 5 Penner Road,

Havant, PO9 1QZ

oska.uk.com

0845 381 0600

Table of contents

Other OSKA Personal Care Product manuals

Popular Personal Care Product manuals by other brands

nCase

nCase SmartCase Quick setup

AgeGracefully

AgeGracefully CarbonBond quick start guide

Gaiam restore

Gaiam restore 05-61830 Setup, Workout Tips and Care & Safety Guide

ProMed

ProMed ProM-660 user manual

Ossur

Ossur REBOUND AIR WALKER LT Instructions for use

Panasonic

Panasonic EW1611 operating instructions