1. BEFORE YOU BEGIN............................................................................................................................. 4

1.1 Confirming the Tag ............................................................................................................................ 4

1.2 Transportation Considerations .......................................................................................................... 4

1.3 Storage Considerations..................................................................................................................... 4

2. GENERAL ............................................................................................................................................... 5

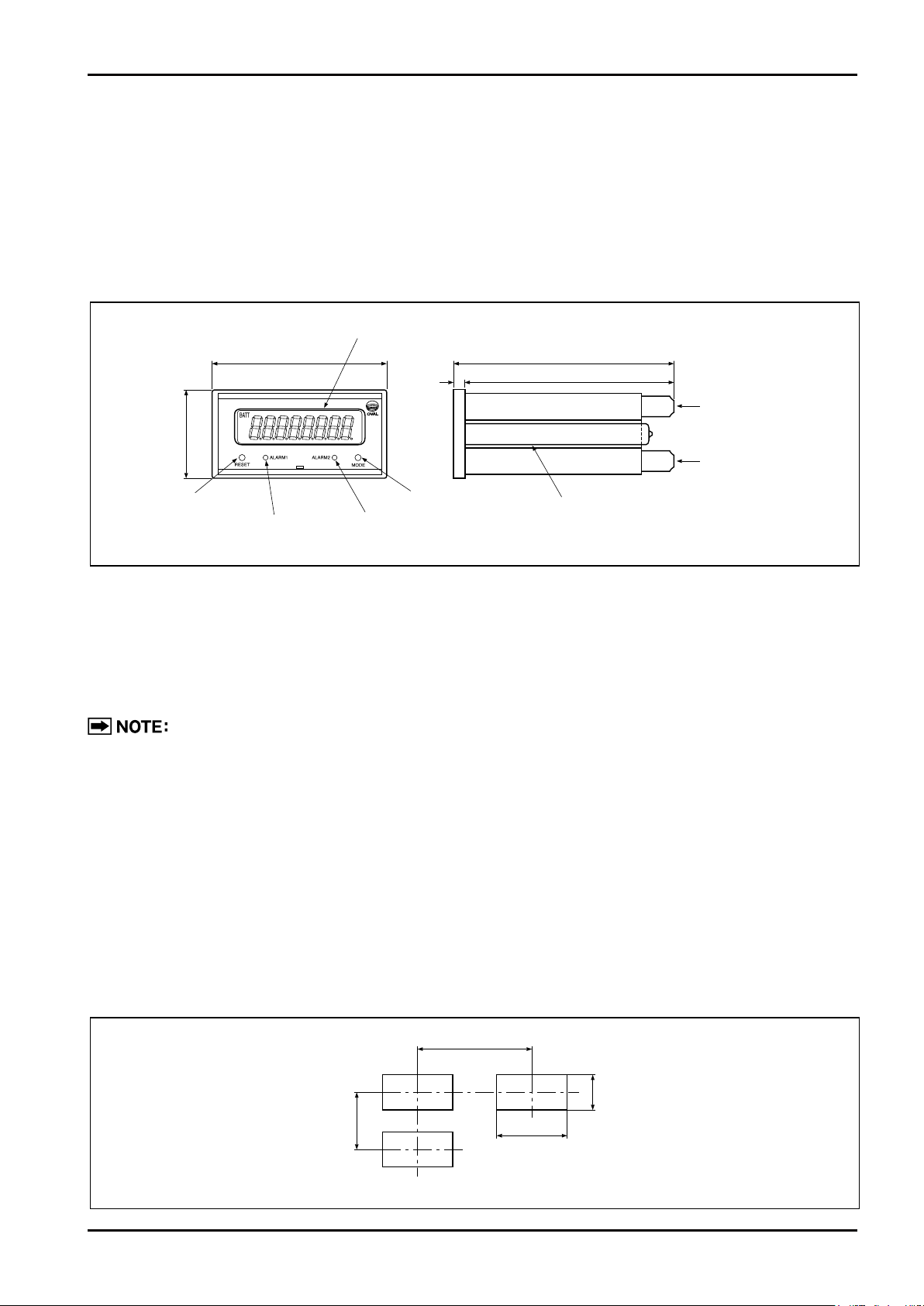

3. PART NAMES AND OUTLINE DIMENSIONS ....................................................................................... 5

4. INSTALLATION....................................................................................................................................... 5

4.1 Installation Location .......................................................................................................................... 5

4.2 Installation ......................................................................................................................................... 5

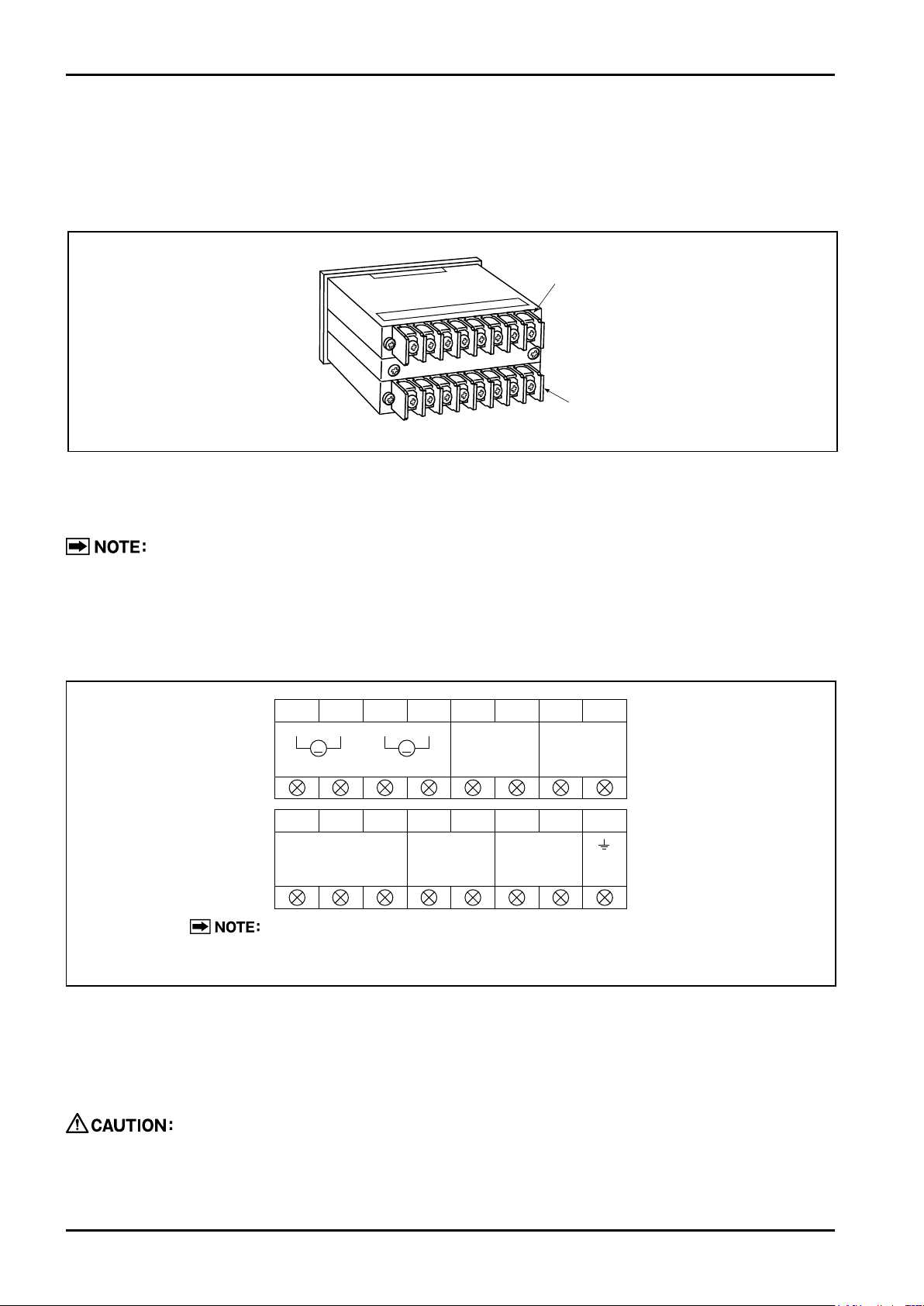

5. WIRING ................................................................................................................................................... 6

5.1 Cables for Field Wiring...................................................................................................................... 6

5.2 Field Wiring and Electrical Connections............................................................................................ 6

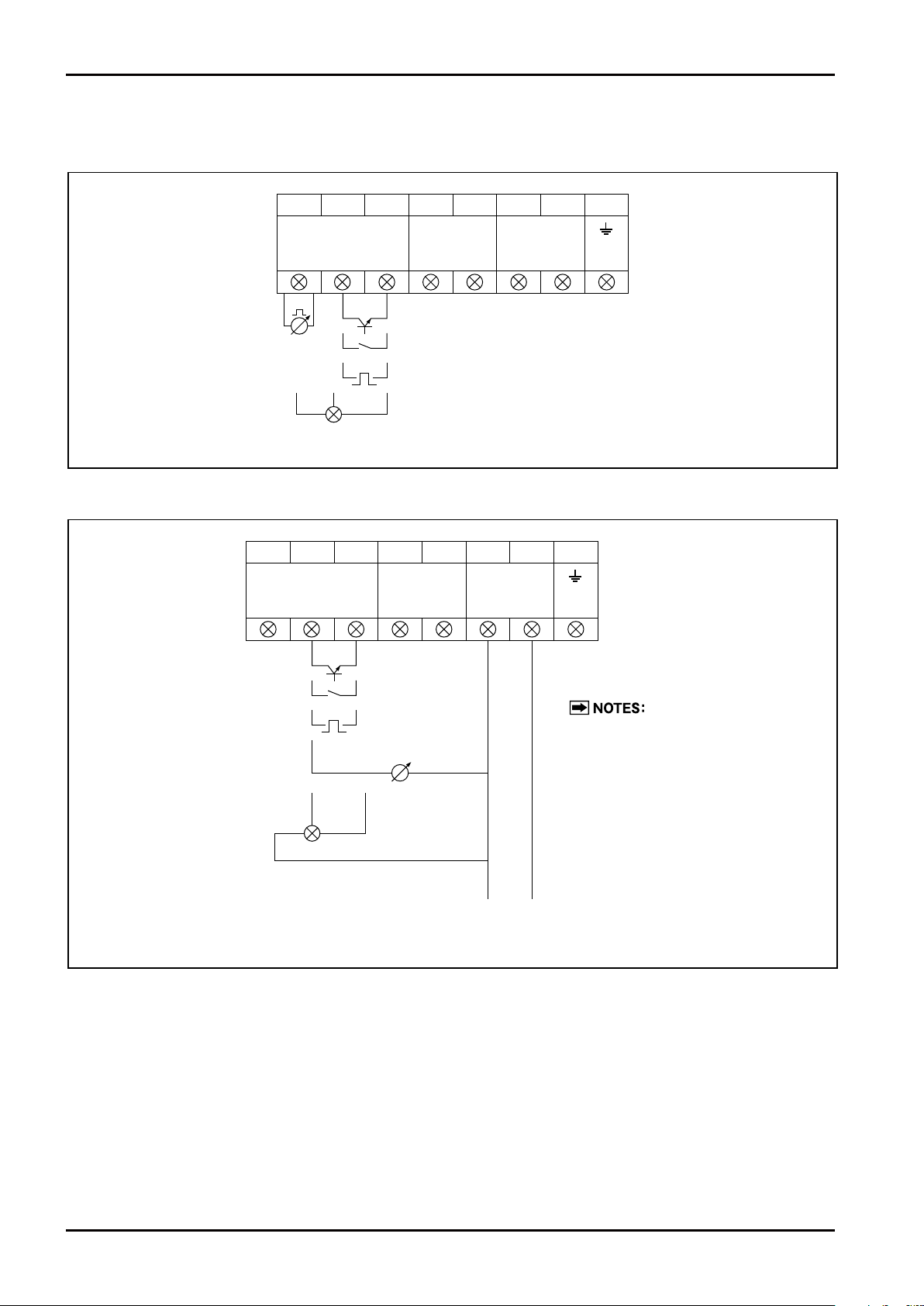

5.3 Terminal Block for External Connections .......................................................................................... 6

5.4 Electrical Connections by Type of Input Signal ................................................................................. 8

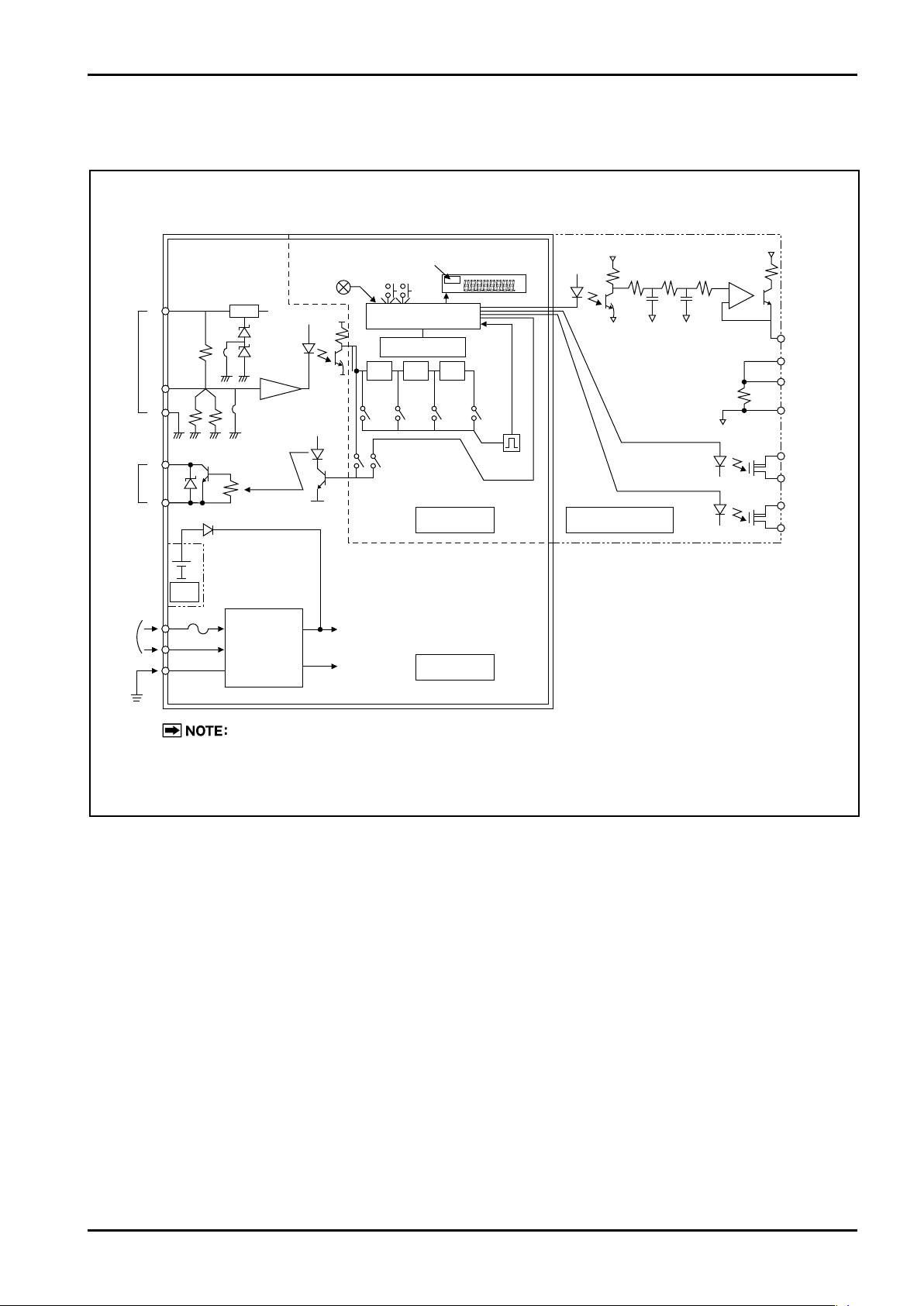

6. BLOCK DIAGRAM.................................................................................................................................. 9

7. FUNCTIONS AND OPERATION .......................................................................................................... 10

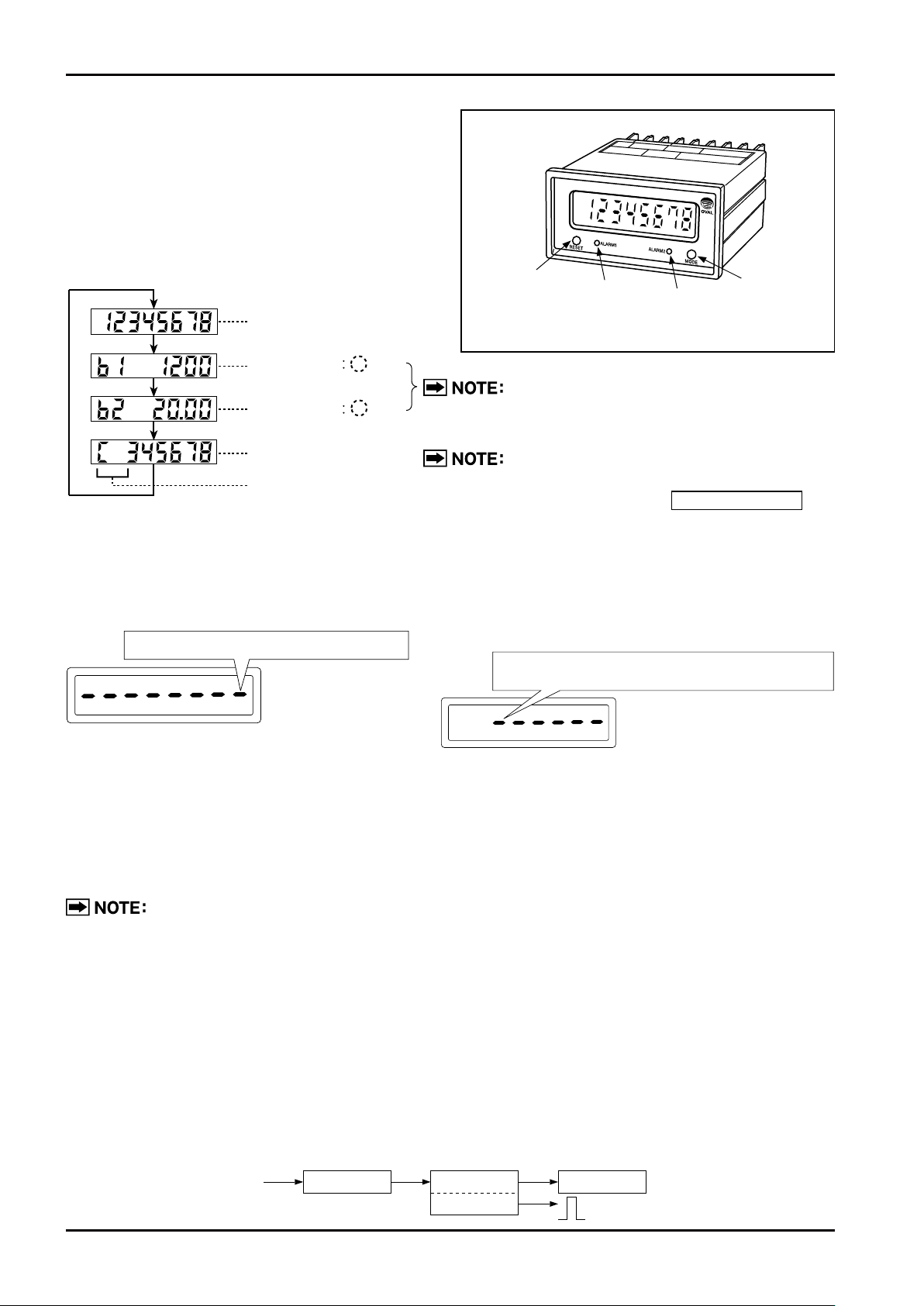

7.1 LCD Counter Display ...................................................................................................................... 10

7.2 About the Displayed Messages during Operation ........................................................................... 10

7.3 Computing Formula for Total Flow and Instantaneous Flowrates ................................................... 10

7.4 Jumper, Switch, Potentiometer Setup and Adjustment ....................................................................11

7.4.1 Construction of Internal Electronics Assembly ...........................................................................11

7.4.2 How to Remove Internal Electronics Assembly..........................................................................11

7.4.3 Waveshaping Function .............................................................................................................. 12

7.4.4

Setup of Other Functions (common to EL0122/0123) LCD Board SW3

......................................... 13

7.4.5 How to Change Output Signal and Pulse Width (option) .......................................................... 13

7.4.6

Parameter Setup, Alteration, and Adjustment in Analog Output Circuit (option)........................ 13

7.5 Parameter Setup Procedure ........................................................................................................... 14

7.5.1 Procedure to Modify a Parameter ............................................................................................. 14

7.5.2 Procedure to Enter a Parameter ............................................................................................... 14

7.5.3 About Dummy Output Features (special functions)................................................................... 16

7.5.4 Parameter Initialization.............................................................................................................. 16

7.5.5 About Alarm Output (option) ...................................................................................................... 17

7.5.6 About Error Messages............................................................................................................... 18

●Table 7.5 Menu Trees and Switch Operation................................................................................... 20

●Table 7.6 Parameter List.................................................................................................................. 20

8. BATTERY REPLACEMENT.................................................................................................................. 22

8.1 About the Batteries.......................................................................................................................... 22

8.2 Battery Replacement....................................................................................................................... 22

CONTENTS