M43-31334&5 REV A

INTERNAL

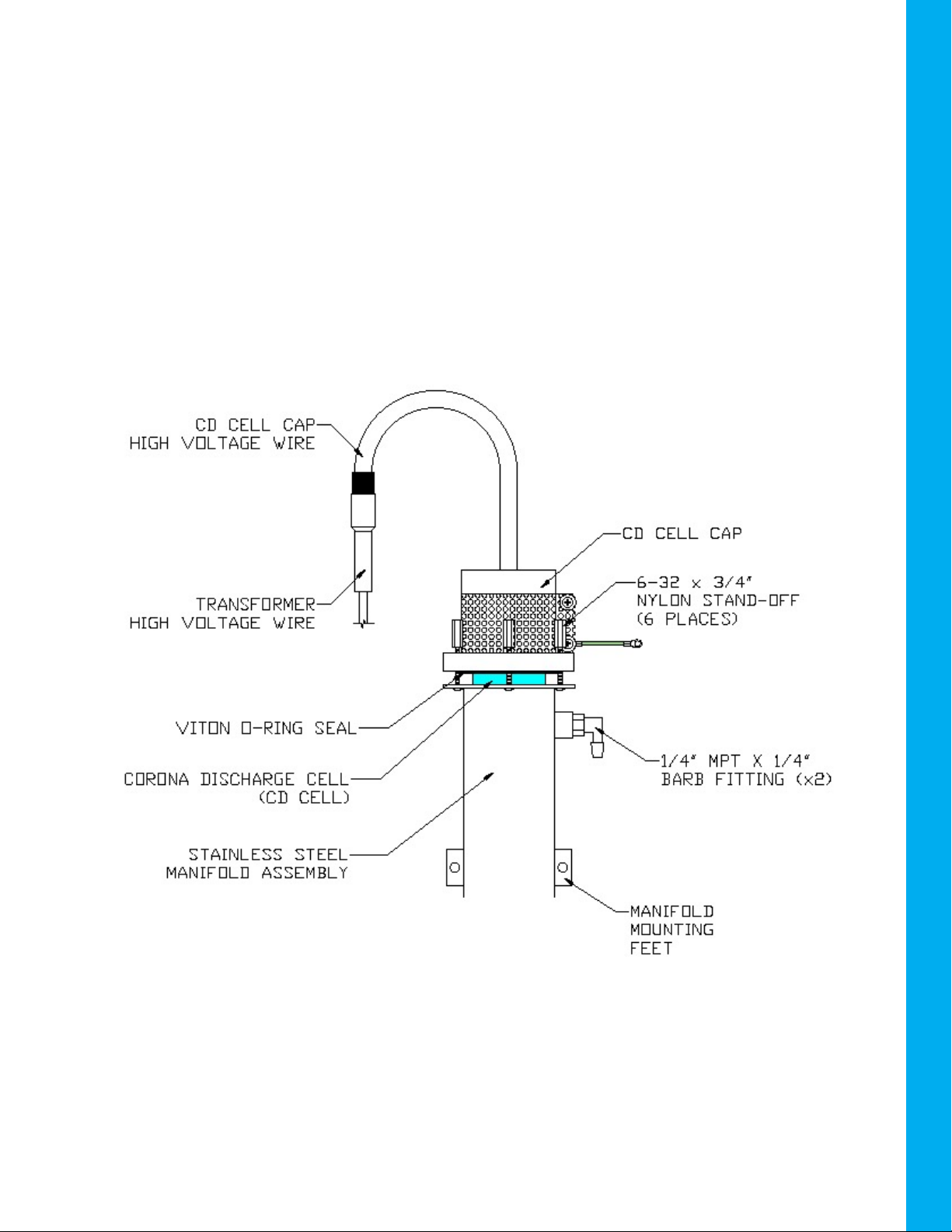

The operating environment inside the chassis is also important. Maintaining a clean, dry unit will

increase overall performance and extend service life. A common cause of failure is un-contained

corona (electrical arcs) within the chassis environment. Moisture and dust are facilitators of this

condition. They both help set up a “path” for the corona to develop and follow. Once established,

corona usually does not stop until it has become severe enough to cause catastrophic failure of

the corona discharge cell or manifold, and subsequently blows the fuse. Note: If this condition

develops, contact the manufacturer.

2.2 Internal Air ow Specications

As mentioned in the Theory of Operation section, Cold Plasma Corona Discharge relies upon a

ow of air passing between the corona discharge cell and the perforated grid to produce ozone

and keep the corona cell and manifold cool.

The rate at which air is drawn (or forced) through the ozone generator is user adjustable. You

may ne-tune the ow rate to best suit your specic application. However, in no case should the

airow rate be allowed to drop below the minimum values specied below. Failure to provide

minimum airow rates may allow your ozone generator to develop excessive heat, possibly

leading to equipment failure.

The minimum air ow rate is: 3 SCFH (1.5 LPM).

The maximum air ow rate is: 20 SCFH (9.5 LPM).

2.3 Input Air Preparation

Regardless of the method of ozone generation, properly preparing the input air (feed gas) will

pay huge dividends in performance and reliability. Ozotech, Inc. does not recommend the use

of any AIM series ozone generator without air preparation. Warranty coverage of your ozone

generator is contingent upon operation with air preparation equipment.

The key to air preparation is in the removal of hydrogen (H) and nitrogen (N) found in ambient air.

When atoms of hydrogen and nitrogen are subject to corona discharge (cold spark or otherwise),

by-products such as nitrous acid (HNO2) and nitric acid (HNO3) are formed. The formation of

these compounds inhibits performance and increases the frequency of maintenance.

To understand how performance is aected, we must recall from the Theory of Operation section

that ozone is created by splitting an oxygen molecule (O2), and then joining the liberated oxygen

atoms (O) with intact oxygen molecules.

Imagine that in addition to oxygen molecules, your feed gas also contains hydrogen and nitrogen

atoms. After being subjected to corona, some of the hydrogen and nitrogen atoms will attach

themselves to intact ozone molecules, forming HNO3, or nitric acid. Others will attach themselves

to oxygen molecules, forming HNO2, or Nitrous acid. It is the formation of these compounds

that reduces performance potential. It is simple to understand why. If ozone molecules were not

being “used” by hydrogen and nitrogen in the formation of acids, more would be available to be

used in oxidation. Likewise, if oxygen molecules were not“used” to form acids, they would be

available for the creation of more ozone.

2