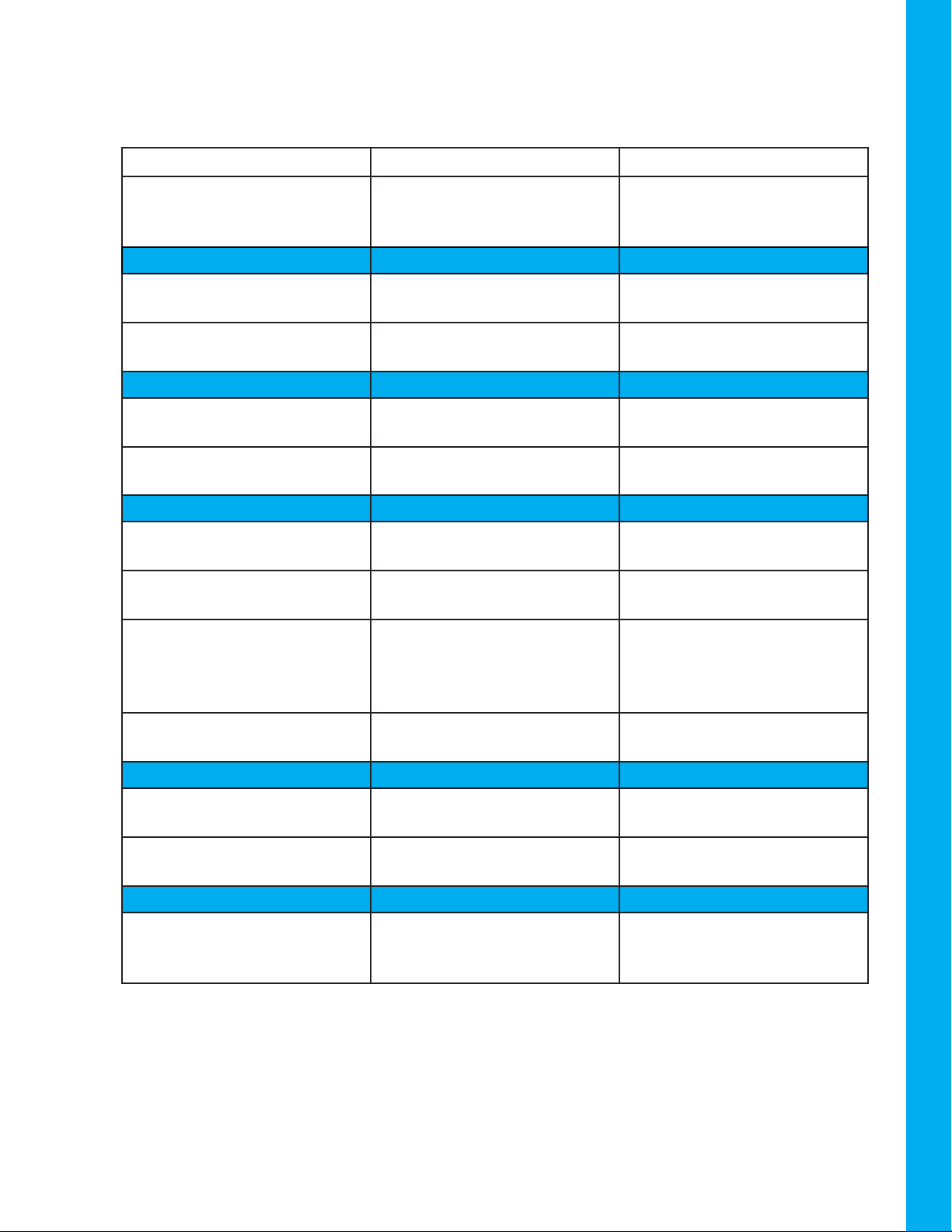

System Possible Cause Solution

Unit doesn’t turn on Unit is not connected to pow-

er source, or is connected to

improper power source

Refer to Input Power Require-

ments, section 4.0, for proper

electrical requirements

Red light on power supply will

not illuminate

Improper outlet voltage Verify power at outlet

Damaged or defective power

supply

Replace power supply

Green light on ozone genera-

tor will not illuminate

Damaged or defective power

supply

Check power supply

operation; replace if necessary

Loose or disconnected inter-

nal wiring

Check internal wiring; remedy

any loose connections

Unit turns on, but no ozone

output

High voltage lead not

connected to CD cell.

Connect frequency driver HV

lead to CD cell

Water has backed up into CD

cell

Clean or replace CD cell.

Cell is plugged with nitric by-

product buildup or particulate

matter

Clean or replace CD cell.

If not installed, install an air

dryer onto ozone generator

air inlet

CD cell not seated in retaining

clips

Re-install CD cell into

retaining clips

Moisture in the inlet and/or

outlet tubing

Improper air preparation Install an air dryer onto ozone

generator air inlet

Yellow discoloration in the

outlet tubing

Nitric byproduct buildup in

CD cell and/or tubing

Clean or replace CD cell and/

or tubing

Water has backed up into the

ozone unit

Failed or missing inline check

valve on ozone output tubing

Clean or replace CD cell.

Replace or install new inline

check valve.

5

6.0 Troubleshooting Guide