3

MAINTENANCE

Good maintenance procedures assure better operation,

fewer repairs and longer life to your machine.

DISCONNECT THE ELECTRICAL PLUG OF THE MA-

CHINE FROM THE ELECTRICAL OUTLET BEFORE

DOING ANY CLEANUP, REPAIRS OR MAINTENANCE

OFTHEMACHINEANDWHENLEAVINGTHEMACHINE

UNATTENDED.

CLEAN THE MACHINE AFTER EACH USE:

1. Wipe the outside with a clean cloth.

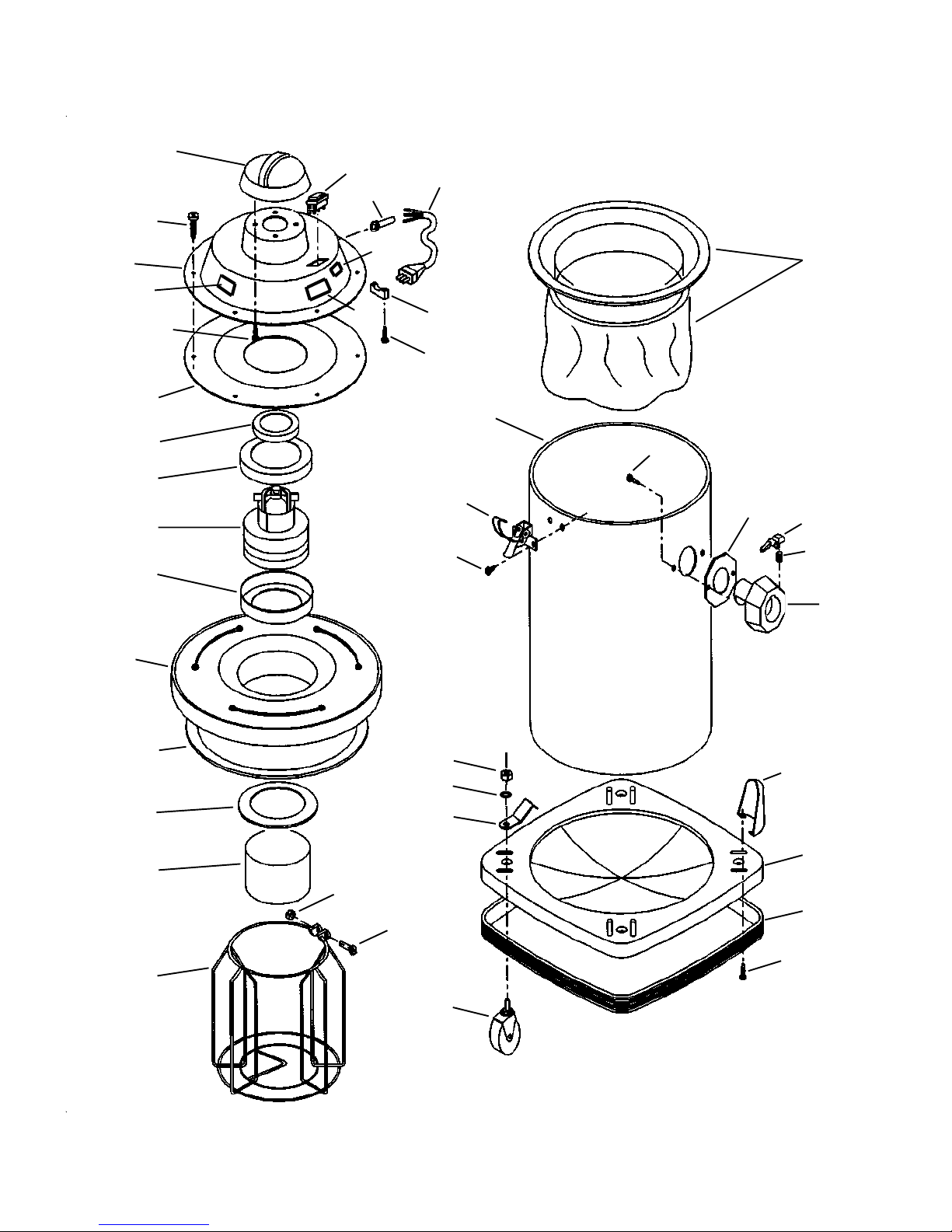

2. Clean the collector tank: Release the clamps on each side

of the tank and head assembly. Lift the head assembly off

and set aside. Lift the filter assembly out of the collector

tank and set aside. Then wipe the inside of the collector tank

with a clean cloth.

3. Empty and check the filter assembly: Empty the recovered

soilage into a suitable container and shake to remove clinging

dirt. Brush the outside of the filter bag to remove embedded

dirt. Check the filter assembly for tears or holes; repair or

replace if necessary. Install the clean filter assembly into the

clean collector tank.

ELECTRICAL CABLE:

Check the cord for any nicks, cuts or damage. Report these to

your supervisor for correction.

VACUUM HEAD ASSEMBLY:

1. Gaskets: Clean the vacuum head gasket and the float shut-off

gasket.

2. Float Shut-Off Device: This should move freely. Remove

any debris or strings from the float cage.

3. Head Assembly: Replace and leave ajar if the collector tank is

damp to prevent mildew.

WHEELS AND CASTERS:

Check these for cuts and nicks. Remove any strings or debris that

may restrict the free movement of the wheels. Wipe the treads

clean.

CARBON BRUSH INSPECTION:

Check for wear at six month intervals or every 600 hours of

operation. The carbon brushes must be replaced if worn shorter

than 3/8 inch.

OPERATING PROCEDURES

WARNING! For the safe operation of this machine follow

the instructions given in this booklet and the training given

by your supervisor. Failure to do so can result in personal

injury and/or damage to machine and property!

DO NOT OPERATE MACHINE IN AN EXPLOSIVE

ENVIRONMENT!

To prepare the machine for operation, make sure it is of the correct

voltage and properly assembled. If in doubt, ask your supervisor.

FOR DRY PICK-UP:

“Dry” refers to material such as dust, dirt, debris and dry foam

shampoo.

1. Release the clamp on each side of the tank and head assembly.

Lift the head assembly off and set it aside.

2. Then lift the cloth filter assembly out of the collector tank.

Clean the cloth filter if needed (reference the “Maintenance”

section).

3. Empty the collector tank of all dust and debris. If the debris

is wet, empty and dry the inside of the tank thoroughly.

4. Place the cloth filter assembly back into the collector tank.

Check for a good seal around the outer filter lip and tank rim.

5. Replace the head assembly and fasten both clamps. Attach

the hose, wand and floor tool of choice (reference page 5).

6. Plug the power cord into a 115-volt, 60 cycle grounded outlet.

7. Turn the machine’s motor on by pressing the rocker switch

which is located on the head assembly.

WARNING! NEVER USE THIS MACHINE TO PICK UP

VOLATILE OR EXPLOSIVE MATERIALS.

FOR WET PICK-UP:

“Wet” refers to liquids such as water, scrub solutions and deter-

gents; NOT VOLATILE OR EXPLOSIVE MATERIALS.

1. Release the clamp on each side of the tank and head assembly.

Lift the head assembly off and set it aside.

2. Then lift the cloth filter assembly out of the collector tank.

Store the filter assembly for future, dry pick-up use. DO

NOT REINSTALL.

3. Empty the collector tank of all dust and debris. Also wipe

the inside of the collector tank to remove clinging dust.

4. Check the float shut-off device on the lower portion of the

head assembly. The float should have free movement. When

the recovered liquid soilage reaches the collector tank capac-

ity, the float will rise to shut off the air flow, stopping the

liquid recovery. This prevents damaging overflow and signals

the operator when to empty the collector tank.

5. Replace the head assembly and fasten both clamps. Attach

the hose, wand and floor tool of choice (reference page 5).

6. Plug the power cord into a 115-volt, 60 cycle grounded outlet.

7. Turn the machine’s motor on by pressing the rocker switch

which is located on the head assembly.