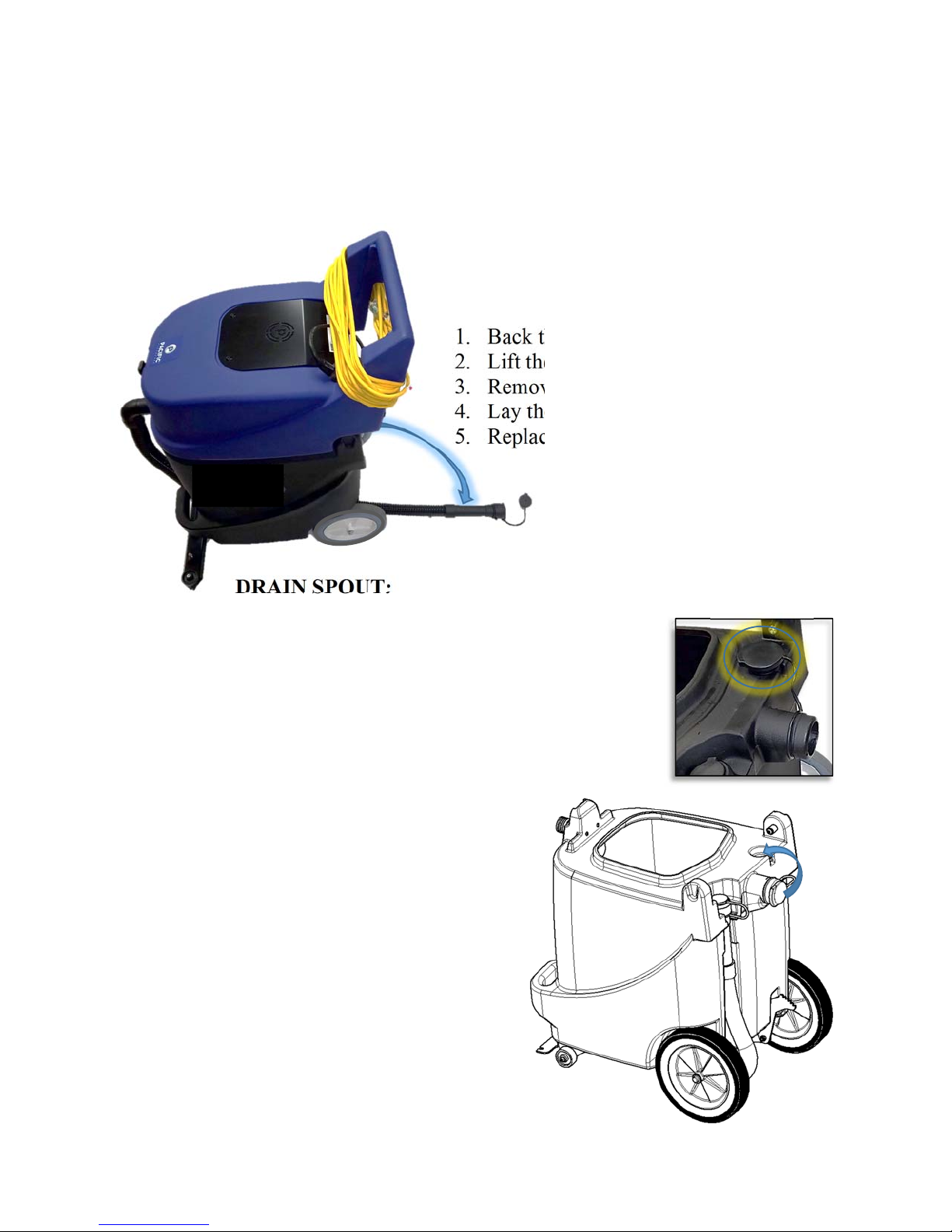

Pacific WDV-18 User manual

Other Pacific Vacuum Cleaner manuals

Pacific

Pacific PWD 600 Installation and operation manual

Pacific

Pacific GULPER 16SV Installation and operation manual

Pacific

Pacific WAV-30 User manual

Pacific

Pacific GENIUS 14 Installation and operation manual

Pacific

Pacific TopVac User manual

Pacific

Pacific RAPID VAC Installation and operation manual

Pacific

Pacific ARROW User manual

Pacific

Pacific WAV-26 User manual

Pacific

Pacific Upright Vacuum Cleaner User manual

Pacific

Pacific Aura Installation and operation manual

Pacific

Pacific WDV-18 User manual

Pacific

Pacific Performance 127G User manual

Pacific

Pacific PV-12 Installation and operation manual

Pacific

Pacific GULPER 12SS Installation and operation manual

Pacific

Pacific PV-12 Installation and operation manual

Pacific

Pacific WIZ Installation and operation manual

Pacific

Pacific 549401 User manual