NOTE:- ØEquipment that fails inspection in any way must immediately be

removed from use, or repaired by an entity approved by the

ØWorkplace conditions, including, but not limited to, ame, manufacturer.

corrosive chemicals, electrical shock, sharp objects,

machinery, abrasive substances, weather conditions, and ØNo on-site repair of equipment unless explicitly permitted by the

uneven surfaces, must be assessed by a Competent Person manufacturer.

before fall protection equipment is selected.

ØEquipment subjected to forces of fall arrest must immediately

ØThe analysis of the workplace must anticipate where workers be removed from use. Snap hooks, karabiners, and other

will be performing their duties, the routes they will take to reach connectors must be selected and applied in a compatible

their work, and the potential and existing fall hazards they may fashion. All risk of disengagement must be eliminated. All snap

be exposed to. Fall protection equipment must be chosen by a hooks and karabiners must be self-locking and self-closing, and

Competent Person. Selections must account for all potential must never be connected to each other.

hazardous workplace conditions. All fall protection equipment

should be purchased new and in an unused condition. ØAge, tness, and health conditions can seriously affect the

worker should a fall occur. Consult a doctor if there is any

ØFall protection systems must be selected and installed under reason to doubt a user's ability to withstand and safely absorb

the supervision of a Competent Person, and used in a fall arrest forces or perform set-up of equipment.

compliant manner.

ØPregnant women and minors must not use this equipment.

ØFall protection systems must be designed in a manner Physical harm may still occur even if fall safety equipment

compliant with all federal, state, and safety regulations. functions correctly. Sustained post-fall suspension may result in

serious injury or death. Use trauma relief straps to reduce the

ØForces applied to anchors must be calculated by a Competent effects of suspension trauma. Allowable individual worker

Person. weight limit (including all equipment), unless explicitly stated

otherwise, is 40-100 kgs..

ØHarnesses and connectors selected must be compliant with

manufacturer's instructions, and must be of compatible size MAINTENANCE, CLEANING, AND STORAGE

and conguration.

ØRepairs to C0850 can only be made competent person or

ØA pre-planned rescue procedure in the case of a fall is required. an entity authorized by manufacturer. If a C0850 fails

The rescue plan must be project specic. The rescue plan must inspection in any way, immediately remove it from service, and

allow for employees to rescue themselves, or provide an contact manufacturer to inquire about its return or repair.

alternative means for their prompt rescue.

ØCleaning after use is important for maintaining the safety and

ØStore rescue equipment in an easily accessible and clearly longevity of C0850.

marked area.

ØRemove all dirt, corrosives, and contaminants from C0850

ØTraining of Authorized Persons to correctly erect, disassemble, before and after each use. If C0850 cannot be cleaned with

inspect, maintain, store, and use equipment must be provided plain water, use mild soap and water, then rinse and wipe dry.

by a Competent Person. NEVER clean C0850 with corrosive substances.

ØTraining must include the ability to recognize fall hazards, ØWhen not in use, store equipment where it will not be affected by

minimize the likelihood of fall hazards, and the correct use of heat, light, excessive moisture, chemicals, or other degrading

personal fall arrest systems. elements.

ØNEVER use fall protection equipment of any kind to hang, lift, LIMITATIONS

support, or hoist tools or equipment, unless explicitly certied

for such use. Fall Clearance: There must be sufcient clearance below the

anchorage connector to arrest a fall before the user strikes the

ØMaintenance of equipment must be done according to ground or an obstruction. When calculating fall clearance, account

manufacturer's instructions. Equipment instructions must be for a MINIMUM 3'safety factor, deceleration distance, user height,

retained for reference. length of lanyard/SRL, and all other applicable factors.

ØPrior to EACH use, all equipment in a fall protection system Swing Falls: Prior to installation or use, make considerations for

must be inspected for any potential or existing deciencies that eliminating or minimizing all swing fall hazards. Swing fall occurs

may result in its failure or reduced functionality. IMMEDIATELY when the anchor is not directly above the location where a fall

remove equipment from service if any deciencies are found. occurs. Always work close to in line with anchor point as possible.

Swing falls signicantly increase the likelihood of serious injury or

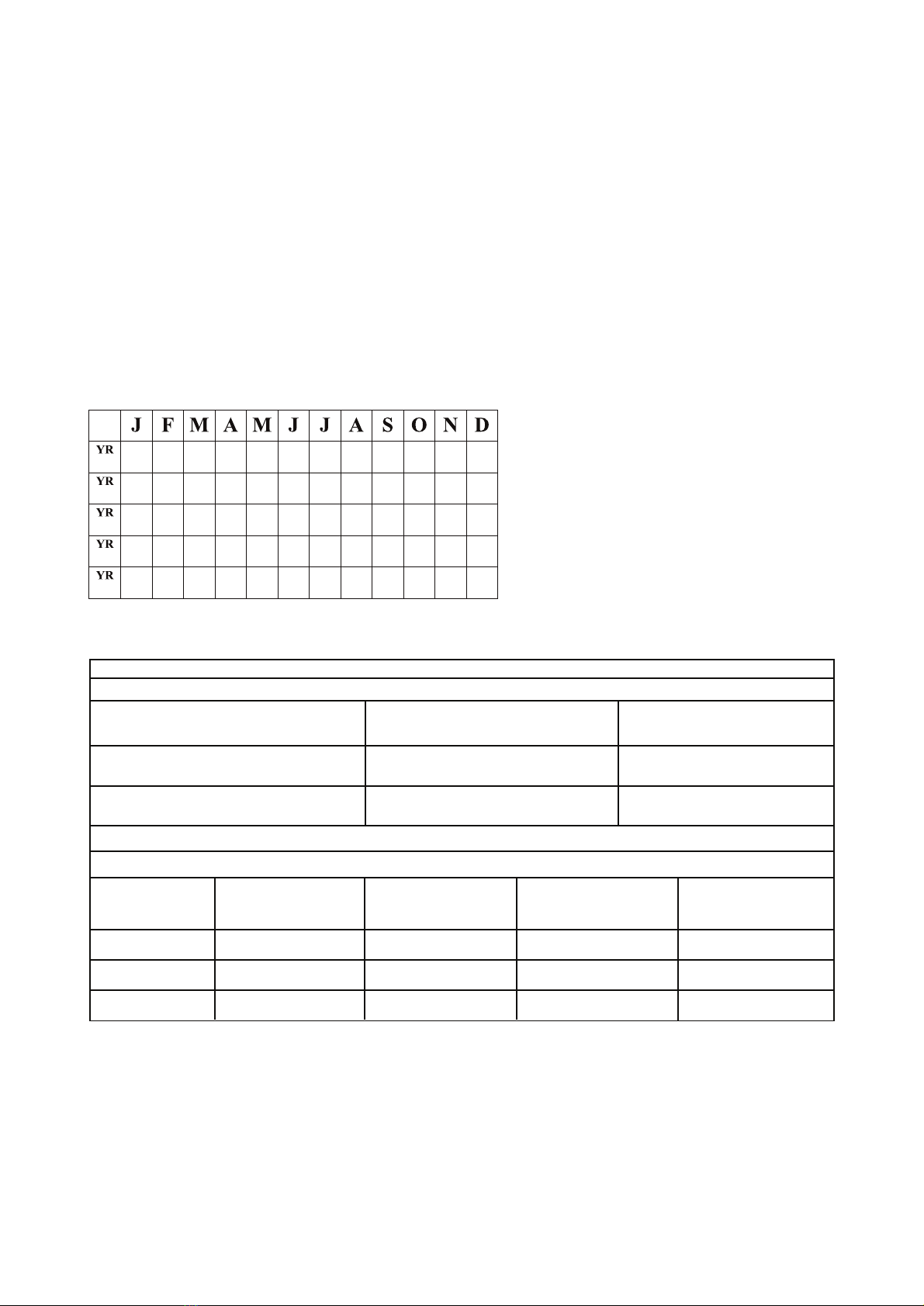

ØEquipment must be inspected by a Competent Person at least death in the event of a fall.

every six months. These inspections must be documented in

equipment instruction manual and on equipment inspection Compatibility: When making connections with C0850,

grid label. eliminate all possibility of roll-out. Roll-out occurs when interference

between a hook and the attachment point causes the compatible

ØEquipment must be inspected for defects, including, but not with C0850 by a competent person. All connector gates must be

limited to, the absence of required labels or self closing and self-locking and withstand minimum load of 3600

lbs.

markings, improper form/t/function, evidence of cracks, sharp

edges, deformation, corrosion, excessive heating, alteration, Vertical Lifeline Assembly (VLA): Specic Applications

excessive wear, fraying, knotting, abrasion, and absence of

parts.

Page 2 of 4

Direction of Usege

Close the flange and

Tigten the screw nut

Direction of Usege

Now, Connect The

System with your

Harness using a

karabiner and the

System is ready for

use

Now Install the Rope

Into The Fall Arrester

Direction of Usege