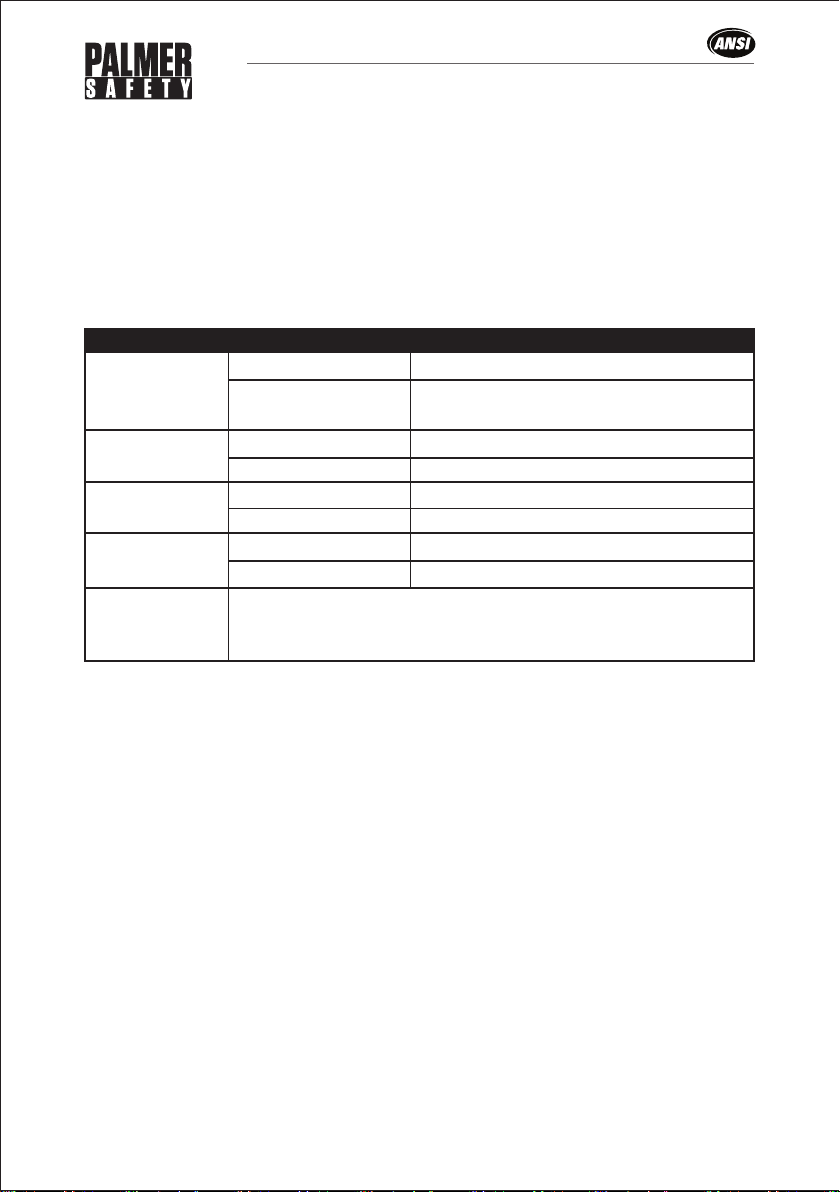

THESE INSTRUCTIONS APPLY TO

THE FOLLOWING MODELS:

H11110005, H11110105, H11210005, H112100341,

H11210105, H134200021, H21110002, H211100052,

H211101031, H21210003, H212100031, H212100031.LG,

H212100031.SM, H21210003123, H212100061,

H212100062, H212100062.2XL, H212100062.3XL,

H212100062.SM, H21210006223, H21210006224,

H212100072, H212100072.2XL, H212100072.3XL,

H212100072.SM, H21210007223, H21210007224,

H212100162, H212100162.2XL, H212100162.3XL,

H212100162.SM, H212100172, H212100172.2XL,

H212100172.3XL, H212100172.SM, H212100574,

H212100574.2XL, H212100574.3XL, H212101031,

H21210111, H212101131, H212101131.SM,

H212101131.XXL, H21210115, H21210116, H212110031,

H212111031, H212300031, H2130111051, H222100041,

H222100081, H222100111, H222100123, H222100141,

H222100141.2XL, H222100141.SM, H222100181,

H222100181.2XL, H222100181.SM, H222100421,

H222101121LG, H222101121MD, H222101121SM,

H222101121XLG, H222101123LG, H222101123MD,

H222101123SM, H222101123XLG, H222101125LG,

H222101125MD, H222101125SM, H222101125XLG,

H222101126LG, H222101126MD, H222101126SM,

H222101126XLG, H222101521, H222101631.2XL,

H222101631.3XL, H222101631LG, H222101631MD,

H222101631XLG, H22310052, H223100521,

H223100521.XL, H22311162, H223111621,

H223111621.LG, H223111621.Med, H223111621.XLG,

H22312162, H22312162.L/XL, H22312162.S/M,

H234300021, H234302122, H234302522

01

Palmer Safety | 6000 Jefferson Hwy | Harahan, LA 70123