7

4. STORAGE

This equipment should be stored in a cool, dry environment away from direct sunlight.

5. INSTALLATION AND USE

l Pivot the locking clip away from the body and then turn the locking screw counter- clockwise until it is

disengaged. The rope grab can now be pivoted open. Inspect as previously outlined.

l When the rope grab is positioned properly, the arrow will be facing up. (The roller attached to the hinge

pin will be pointing down.)

l Lifeline can now be inserted. Only 5/8 inches (16mm) diameter rope should be used.

l Pivot the ring until the gripper does not press against the rope, then close the unit around the rope.

l Tighten the locking screw, it should thread easily and tighten against the rope grab body. The body parts

should be touching. Rotate the locking clip over the dimple into the notch in the body. The locking clip

should rotate easily and stay in the locked position with the help of the detent and bronze thrust washer.

Check that the screw is tight and the clip is totally in the locked position.

l Test mobility: This rope grab is designed to work with minimum effort. To move upward, pull up on the

ring, it should move easily. To move downward, lift up on the ring to release the gripper. The weight of

the unit should move it downwards. To ensure you have proper freedom of movement, repeat the

above steps.

l To test the installation, pull down sharply on the ring. Th e mechanism will lock onto the rope if it is

functioning properly.

6. MAINTENANCE

To clean, use water and a mild soap. Wipe dry with a clean cloth or use low-pressure compressed air.

To lubricate, use light oil such as WD-40. A small amount of oil can be used on pivot and roller bearing points.

Take care to remove any excess oil from the body and surfaces of the rollers to ensure no transfer of oil to

the rope.

7. WARNING

When in use, do not manipulate or hold the fall arrester body or lever. If the user should fall while holding

the rope grab, they could restrict the locking mechanism. This would prevent the device from arresting the

fall. Serious injury or death could result. Maintain the lever of the fall arrester is forced upward by lanyard,

the fall arrester will be able to move freely up/down on the lifeline.

l Rope grabs are designed to be attached to no more than one lifeline.

l Rope grabs are designed to be a part of a fall arrest system for one person with weight (equipment and

person) of 130-310 lbs (59-140 kg).

l Make sure your path is free and clear of obstructions and hazards and that the rope grab does not come

in contact with any outside objects when in use.

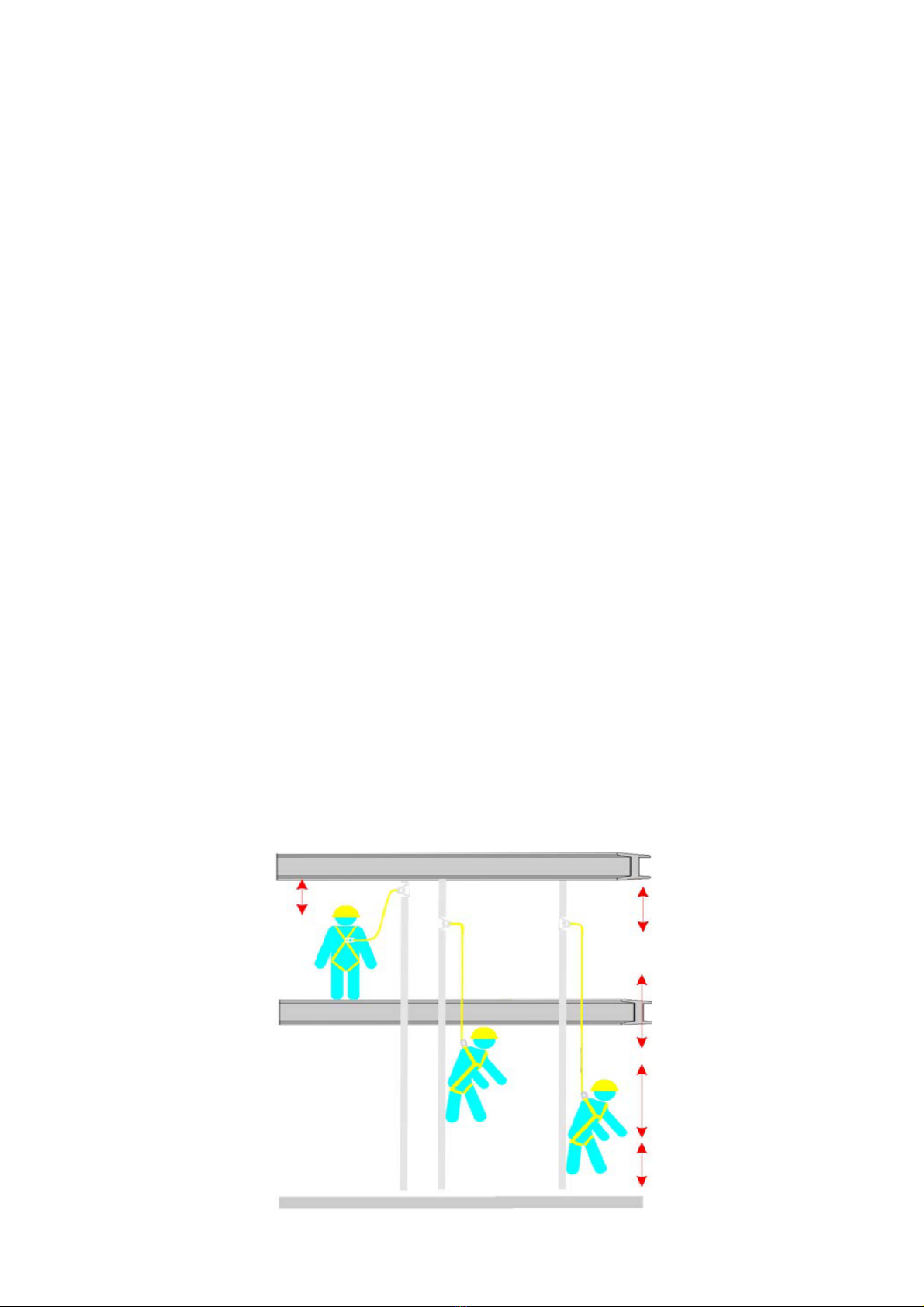

l To minimize falling distance, position the rope grab above the user on the lifeline.

l Rope grabs should be removed from service and discarded once it is subject to a fall.

l After each use, the rope grab should be inspected as mentioned above, then cleaned and stored.

l Avoid exposure to chemical substances or hazards which the fall arrester is not designed to withstand;

failing to do so may result in compromising the material, allowing for the potential of personal injury or

death.

l This product is neither intended for, nor is it suitable for use when the user is positioned on an unstable

surface such as fine grain materials or particulates.

l Users shall not alter the equipment, doing so may result in serious death or injury.

l Care should be taken when using equipment near machines and electrical hazards.

l Contact should be avoided with sharp edges and abrasive surfaces.