INSTRUCTION MANUAL

Safety Control Unit

SF-C21

ME-SFC21 No.0077-22V

Thank you very much for purchasing Panasonic products. Read this Instruction Man-

ual carefully and thoroughly for the correct and optimum use of this product. Kindly

keep this manual in a convenient place for quick reference.

●This is an abridged instruction manual simply explains mounting, wiring and etc.

For detailed handling instructions, refer to “SF-C21 Instruction Manual” avail-

able for download at the following.https://panasonic.net/id/pidsx/global

●Instruction Manuals in the following languages are published on our Web site.

Japanese, English, Chinese, French, Spanish, Italian

• Le manuel d’instructions français est publié sur notre site web.

•

El Manual de Instrucciones en español se encuentra publicado en nuestro sitio web.

• Il manuale di istruzioni italiano è pubblicato sul nostro sito web.

1SAFETY PRECAUTIONS

● Use this device as per its specications. Do not modify this device since its func-

tions and capabilities may not be maintained and it may malfunction.

●This device has been developed / produced for industrial use only.

●Use of this device under the following conditions or environments is not presup-

posed. Please consult us if there is no other choice but to use this device in such

an environment.

1) Operating this device under conditions or environments not described in this

manual.

2)

Using this device in the following elds: nuclear power control, railroad, aircraft,

auto mobiles, combustion facilities, medical systems, aerospace development, etc.

●In case of installing this device to a particular machine, follow the safety regula-

tions in regard to appropriate usage, mounting (installation), operation and main-

tenance. The users including the installation operator are responsible for the intro-

duction of this device.

●Note that this device may be damaged if it is subject to a strong shock (if it is

dropped onto the oor, for example).

●Use this device by installing suitable protection equipment as a countermeasure

for failure, damage, or malfunction of this device.

●Before using this device, check whether the device performs properly with the

functions and capabilities as per the design specications.

●In case of disposal, dispose this device as an industrial waste.

WARNING

♦Machine designer, installer, employer and operator

• The machine designer, installer, employer and operator are solely responsible

to ensure that all applicable legal requirements relating to the installation and

the use in any application are satised and all instructions for installation and

maintenance contained in the instruction manual are followed.

• Whether this device functions as intended to and systems including this de-

vice comply with safety regulations depends on the appropriateness of the ap-

plication, installation, maintenance and operation. The machine designer, in-

staller, employer and operator are solely responsible for these items.

♦Engineer

• The engineer would be a person who is appropriately educated, has wide-

spread knowledge and experience, and can solve various problems which

may arise during work, such as a machine designer, or a person in charge of

installation or operation etc.

♦Operator

• The operator should read this instruction manual thoroughly, understand its

contents, and perform operations following the procedures described in this

manual for the correct operation of this device.

•

In case this device does not perform properly, the operator should report this to

the person in charge and stop the machine operation immediately. The machine

must not be operated until correct performance of this device has been conrmed.

♦Environment

• Do not use a mobile phone or a radio phone near this device.

•

This device starts running approximately 2 seconds after the power is turned

on. Make sure that the control system is operational when the device starts up.

• Do not use the device in places where:

1) The device is exposed to direct sunlight

2) Dew condensation may occur due to sudden changes in temperature

3) The ambient air contains corrosive or ammable gas

4) There is a high level of dust, metallic dust, or salt content

5) The device may be exposed to organic solvents such as benzene, thinner,

or alcohol and/or strong alkaline substances such as ammonia or caustic

soda, or any such substances exist in the ambient air

6) The device may be directly exposed to vibration or impact or to water drops

7) The device may be exposed to interference from nearby high-voltage lines,

high-voltage equipment, power wires, motor equipment, an amateur radio

station or other transmitter, or a device with large switching surges (the de-

vice must be placed at a distance of 100mm or greater from any interfer-

ence sources)

♦Machine in which this device is installed

• This device starts the performance after 2 seconds from the power ON. Have

the control system started to function with this timing.

♦Wiring

• Do not work on (connect or remove etc.) the device while the power is ON.

Failure to follow this precaution could result in an electric shock.

•

All electrical wiring should conform to the regional electrical regulations and laws.

The wiring should be done by engineer(s) having the special electrical knowledge.

• Do not run the wires together with high-voltage lines or power lines or put

them in the same raceway. This can cause malfunction due to induction.

• Do not control the device only at one control output.

♦Maintenance

• When replacement parts are required, always use only genuine supplied re-

placement parts. Do not use a third-party part because doing so could cause

the device to malfunction, possibly resulting in a death or serious injury.

• The periodical inspection of this device must be performed by an engineer

having the special knowledge.

• After maintenance or adjustment, and before starting operation, test this de-

vice following the procedure specied in “ 9MAINTENANCE.”

• Clean this device with a clean cloth. Do not use any volatile chemicals.

♦Others

• Never modify this device. Failure to follow this precaution may cause the de-

vice to malfunction, possibly resulting in a death or serious injury.

2CONFIRMATION OF PACKED CONTENTS

□

SF-C21 1 pc.

□Quick Instruction Manual (Japanese, English, Chinese) 1 pc. each language

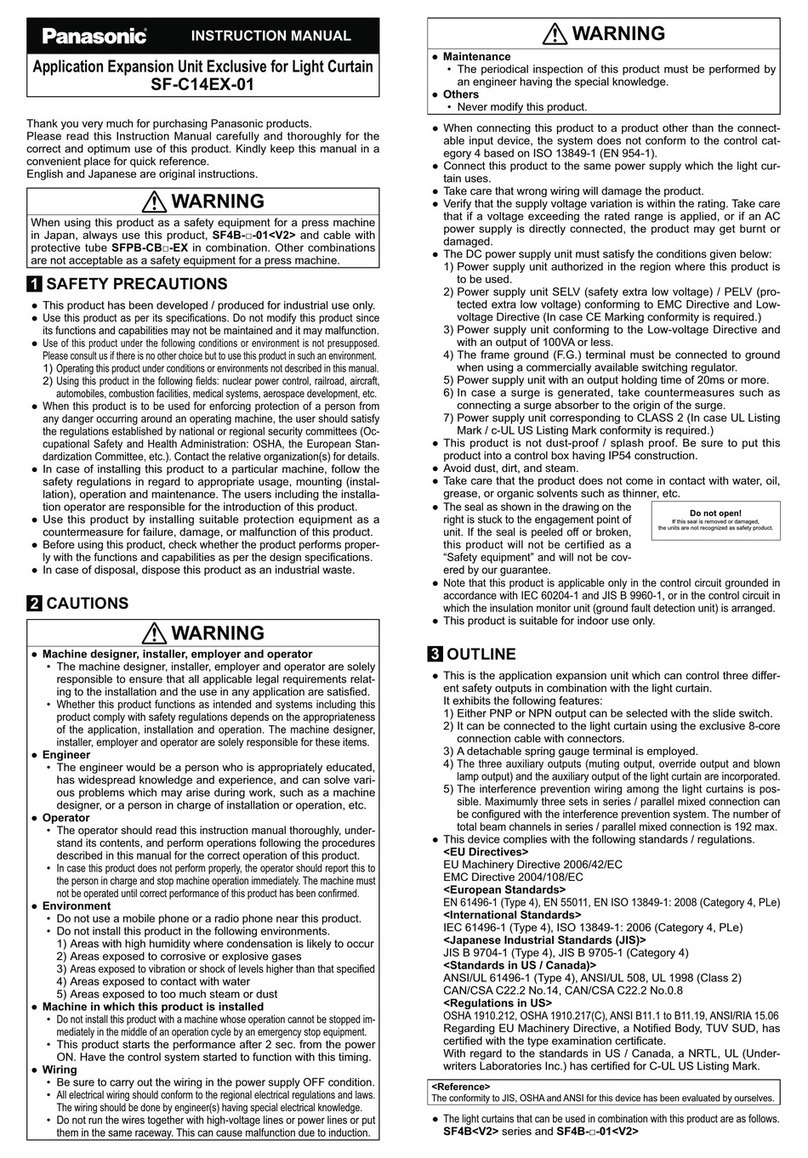

3PART NAMES

Password selection indicator (Orange)

Delay selection indicator (Orange)

Logic selection indicator (Orange)

Mode selection switch

Indicator A USB connector (miniB)

Indicator B

Terminal block

for external

power supply

Indicator C

DIN rail stopper

Terminal block for

internal power supply

DIP switch for RS-485

Terminal block for

RS-485

Rotary switch

Terminal block for

I/O 1

7-segment indicator (Red)

Terminal block for

I/O 2

[Indicator A]

Input 1 indicator (Orange)

Input 5 indicator (Orange)

Input 3 indicator (Orange)

Input 7 indicator (Orange)

Input 2 indicator (Orange)

Input 6 indicator (Orange)

Input 4 indicator (Orange)

Input 8 indicator (Orange)

[Indicator B]

Output 1 indicator (Green)

Auxiliary output 1 indicator (Orange)

Output 3 indicator (Green)

Auxiliary output 3 indicator (Orange)

Output 2 indicator (Green)

Auxiliary output 2 indicator (Orange)

Output 4 indicator (Green)

Auxiliary output 4 indicator (Orange)

[Indicator C]

Operation indicator (Green)

Muting indicator (Orange)

Interlock 1 indicator (Yellow)

Setting indicator (Orange)

Interlock 2 indicator (Yellow)

4MOUNTING

●When installing this device, make sure that it is correctly oriented: The device

must be installed vertically with its indicators and terminal blocks facing the opera-

tor side in order to ensure heat dissipation.

Installed in vertically

reversed orientation

Horizontally installed Sideways installed

●In addition, make sure that the device’s upper, low-

er, left, and right surfaces are spaced by a 50mm or

more from surrounding objects such as other devic-

es and wiring ducts.

50mm

or more

50mm

or more

50mm

or more

50mm

or more

● Do not install the unit above devices which generate heat such as heaters, trans-

formers or large scale resistors.

●In order to eliminate any eects from noise emission, power wires and electro-

magnetic devices should be kept a 100mm or more away from the surfaces of the

device. When installing the unit behind the doors of the control board, be espe-

cially careful to secure clearances as above.

100mm or more

SF-C21

Other

devices